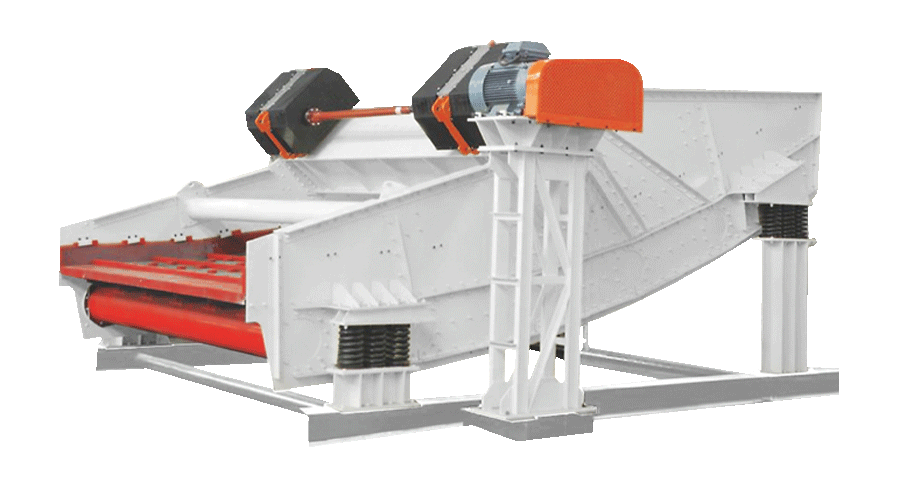

Zhenyuan ZXF series banana screen is a heavy-duty screening machine designed for equal thickness screening, primarily used in industries such as coal and mining for the dry screening of medium and fine-grained materials. It is also widely utilized in coal preparation plants for dewatering and medium removal operations.

This screen employs advanced equal thickness screening principles, offering advantages such as high processing capacity, efficient screening performance, and reliable operation compared to traditional screening machines.

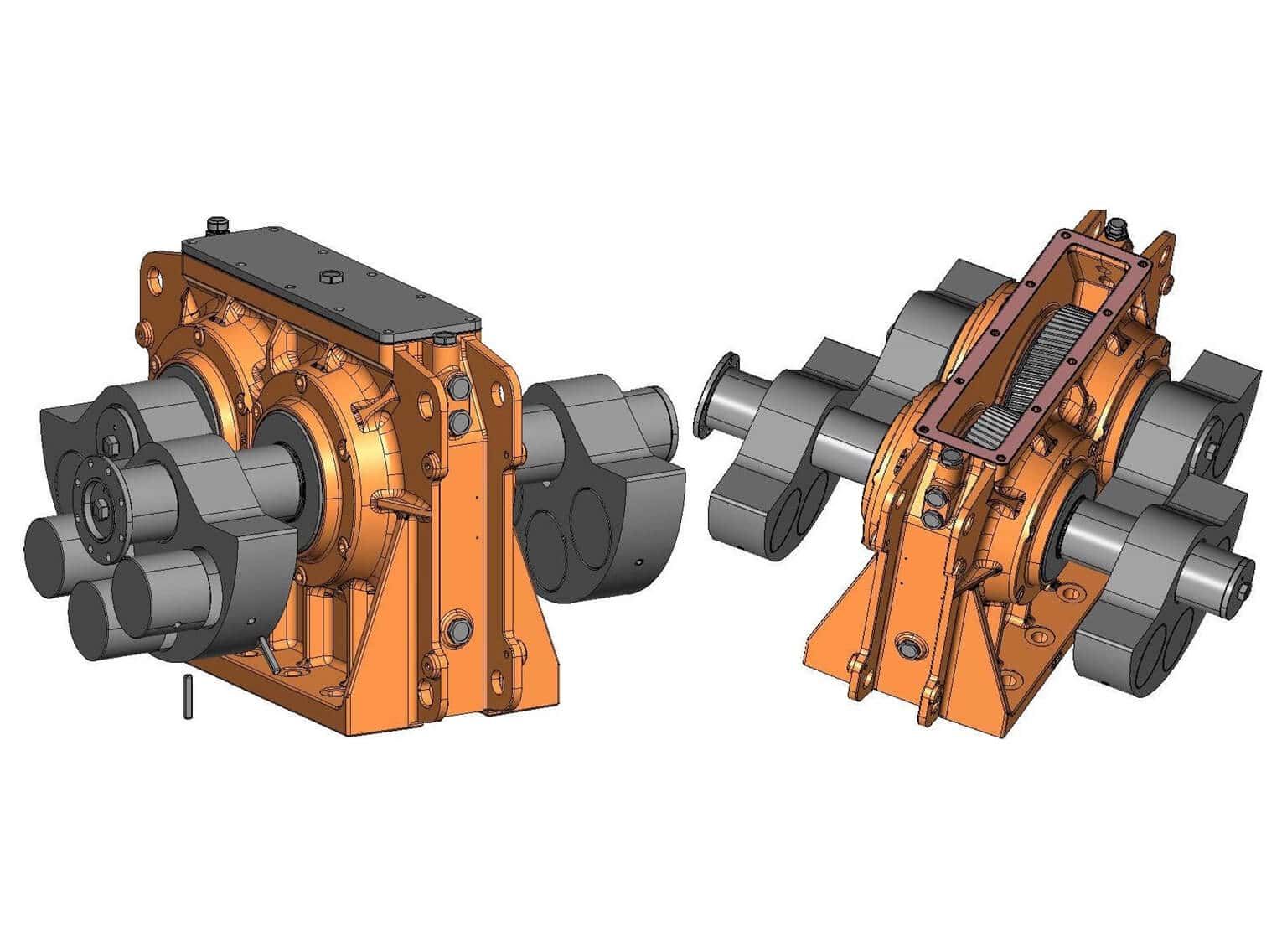

Side plates and rivet holes are formed in one cut using a high-precision laser cutting machine, ensuring high manufacturing accuracy

Riveted connections are used instead of welding, eliminating welding stress. This results in a machine with high overall strength and a long service life

The crossbeam adopts a rectangular hollow structure. After welding, the entire structure undergoes stress-relief treatment. This design ensures a high safety factor and superior strength

The screen plates feature a modular design, offering strong versatility and short delivery cycles

The lower crossbeam's surface, which comes into contact with materials, is coated with polyurea or bonded with TIPTOP high-wear-resistant rubber. This provides the crossbeam with excellent impact resistance, corrosion resistance, and wear resistance

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Screen Plate |

Max. Input Size |

Capacity |

Electrical Motor |

|||

|

Layer(s) |

Area(m2) |

Mesh Size(mm) |

(mm) |

(t/h) |

Power(kw) |

Qty(pcs) |

|

|

ZXF2461 |

1 |

14.64 |

0.5-80 |

300 |

40-550 |

37 |

1 |

|

2ZXF2461 |

2 |

14.64×2 |

0.5-80 |

300 |

40-650 |

45 |

1 |

|

ZXF3061 |

1 |

18.3 |

0.5-80 |

300 |

60-650 |

45 |

1 |

|

2ZXF3061 |

2 |

18.3×2 |

0.5-80 |

300 |

60-750 |

55 |

1 |

|

ZXF3661 |

1 |

21.96 |

0.5-80 |

300 |

80-850 |

55 |

1 |

|

2ZXF3661 |

2 |

21.96×2 |

0.5-80 |

300 |

80-950 |

75 |

1 |

|

ZXF4361 |

1 |

26.23 |

0.5-80 |

300 |

100-1200 |

55 |

1 |

|

2ZXF4361 |

2 |

26.23×2 |

0.5-80 |

300 |

100-1300 |

75 |

1 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Copper Ore

Input Size: 0-300mm

Upper Screen Mesh Size: 40mm

Lower Screen Mesh Size: 16mm

Capacity: 1000-1200TPH

Processing Materials: Bauxite Ore

Input Size: 0-300mm

Upper Screen Mesh Size: 50mm

Lower Screen Mesh Size: 10mm

Capacity: 800-1000TPH