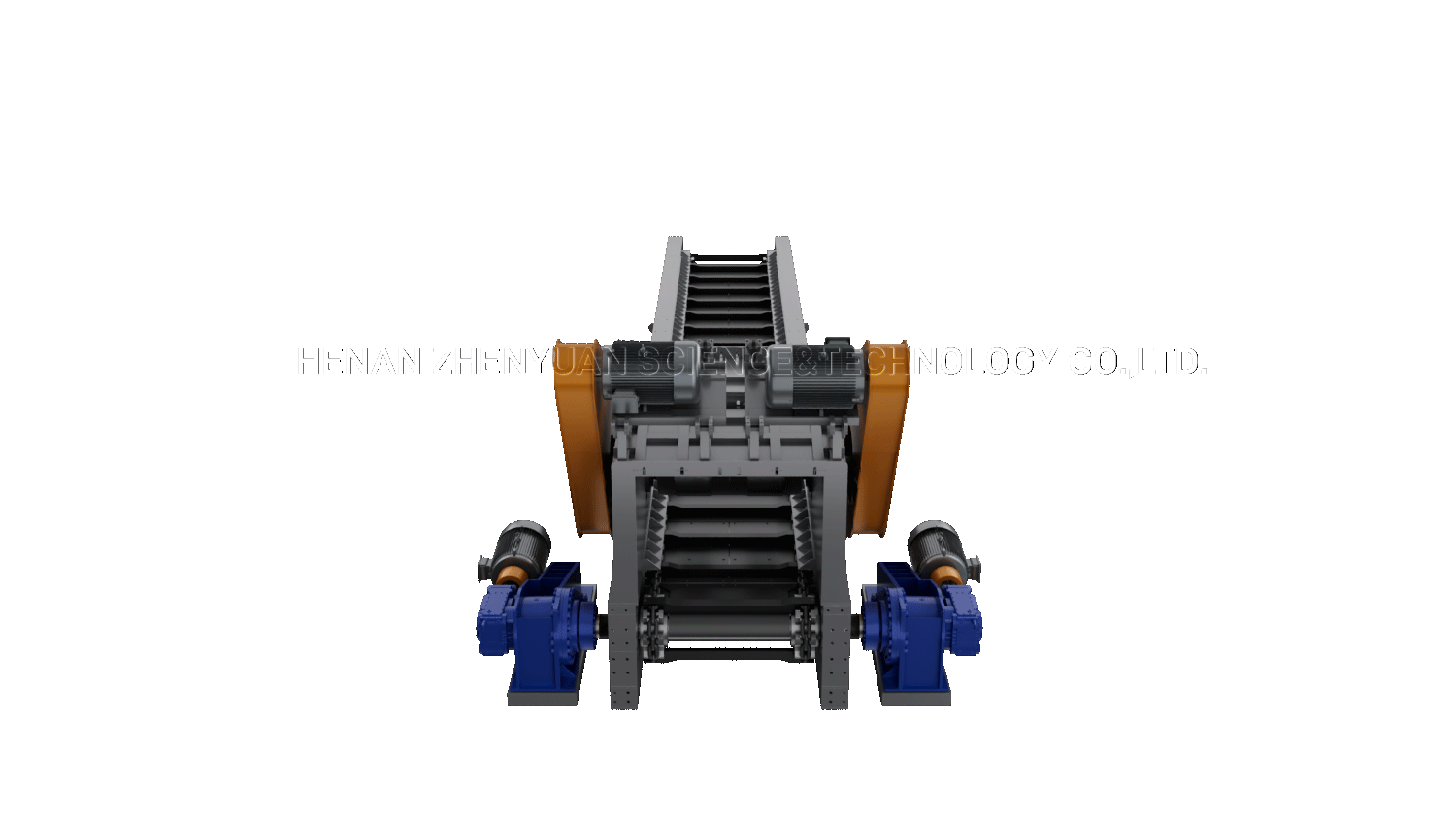

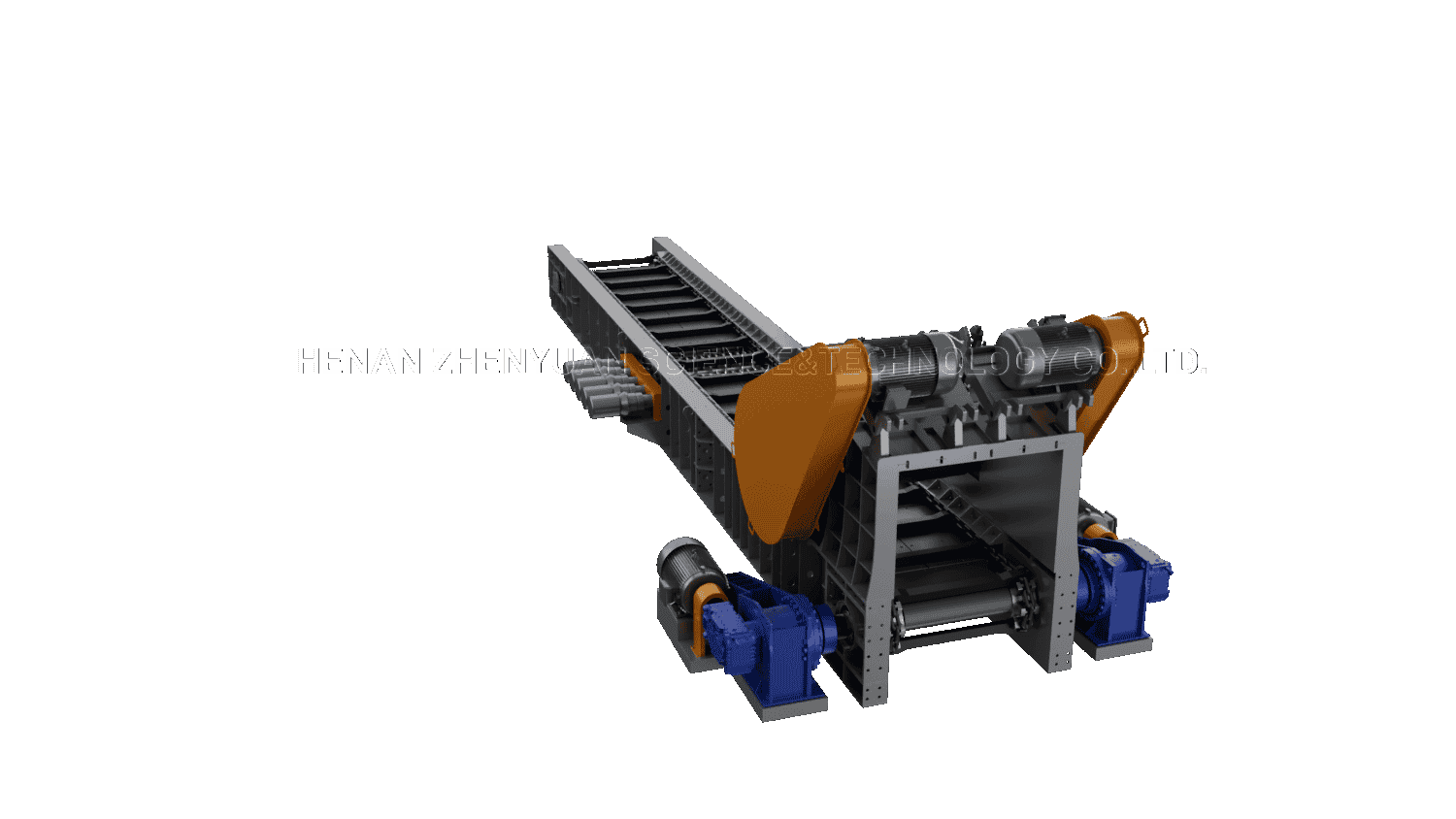

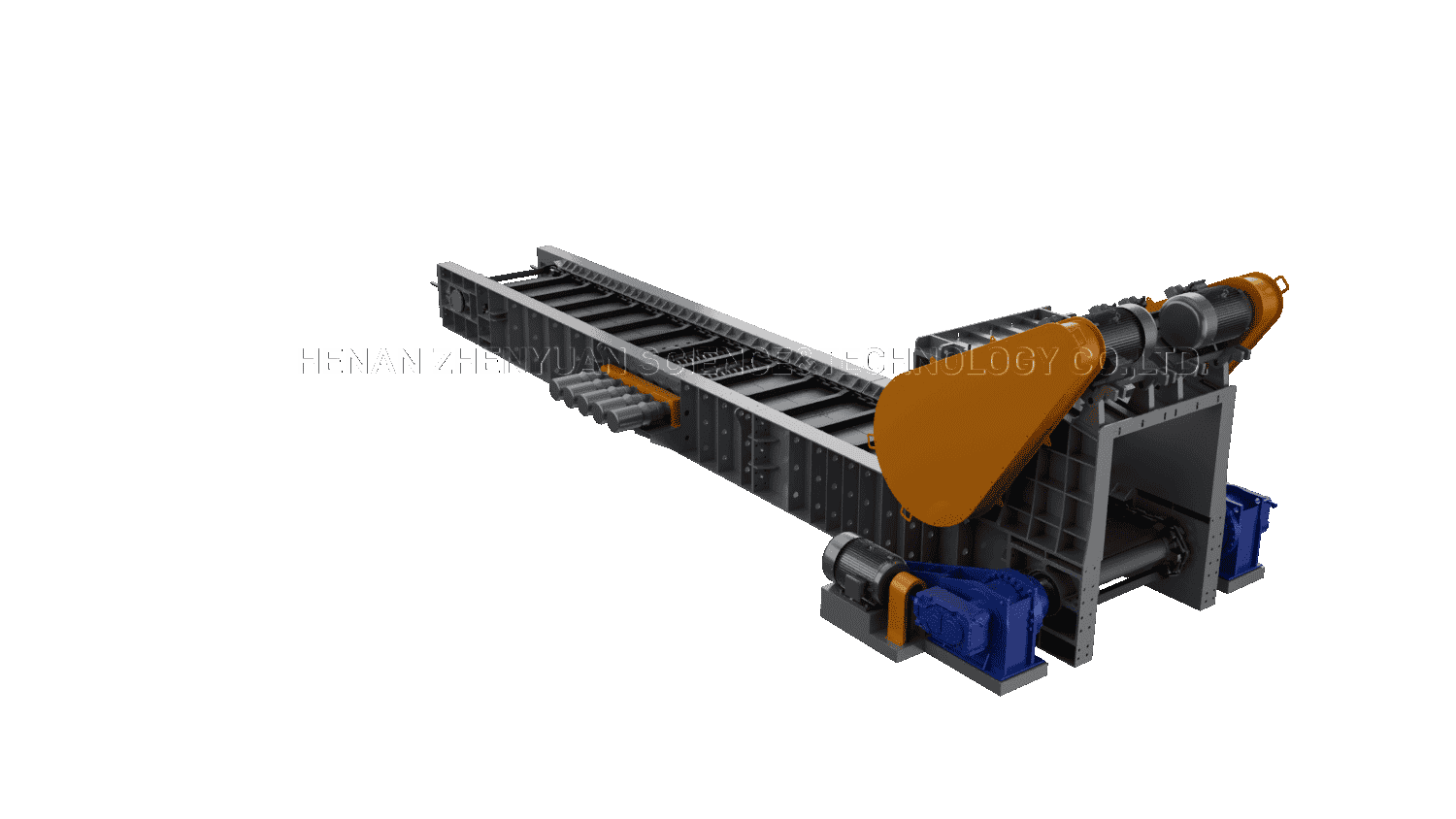

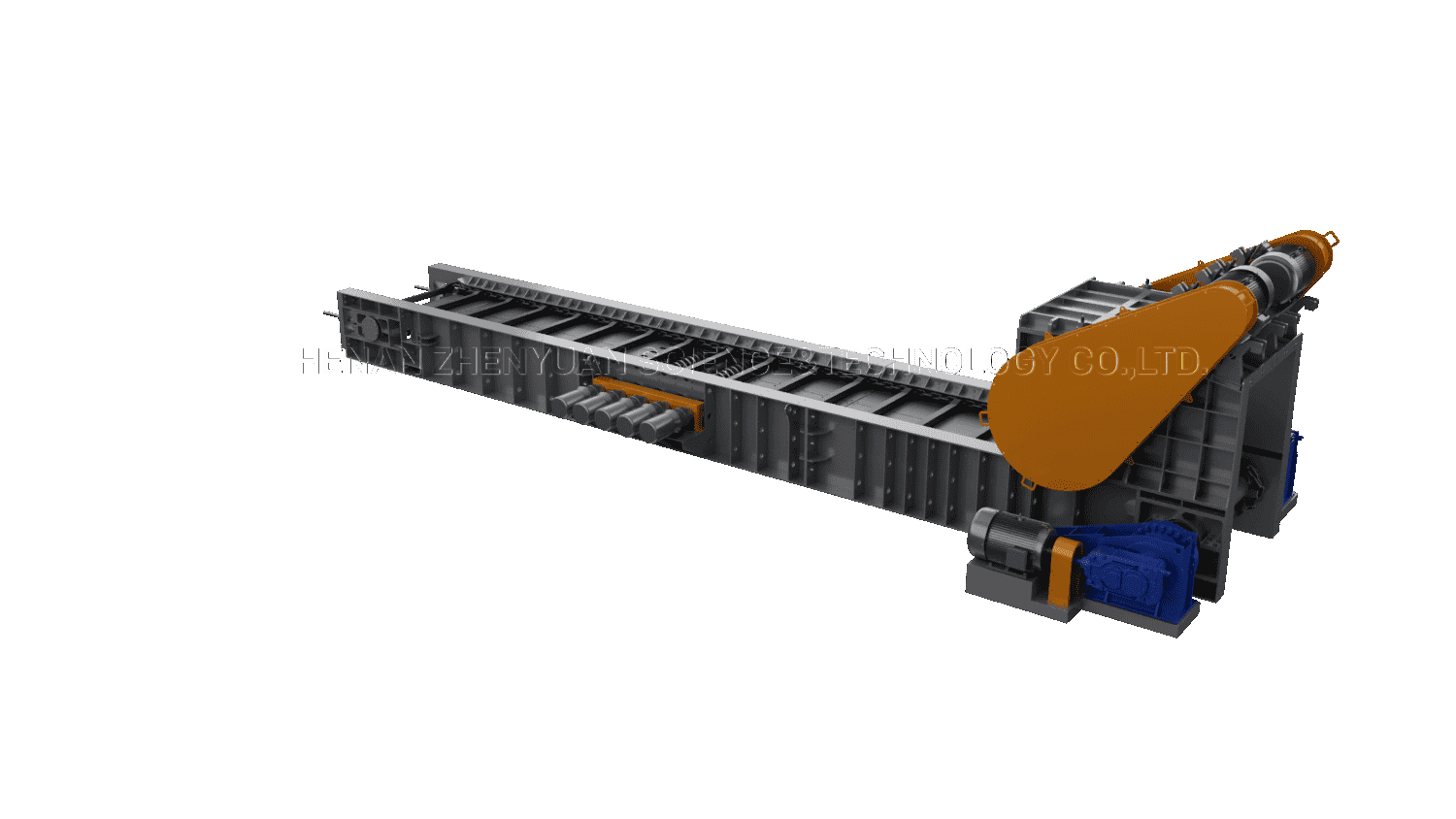

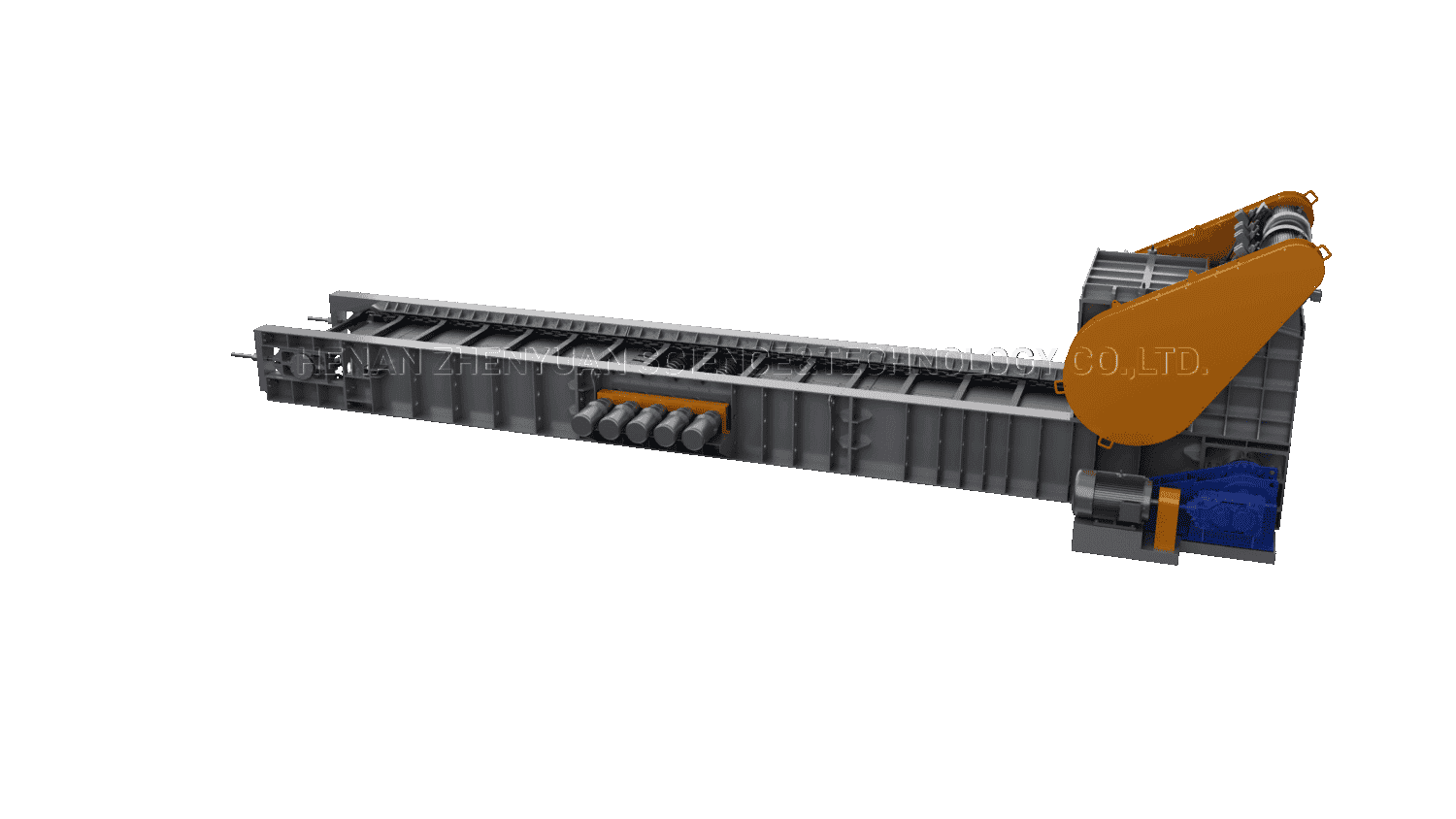

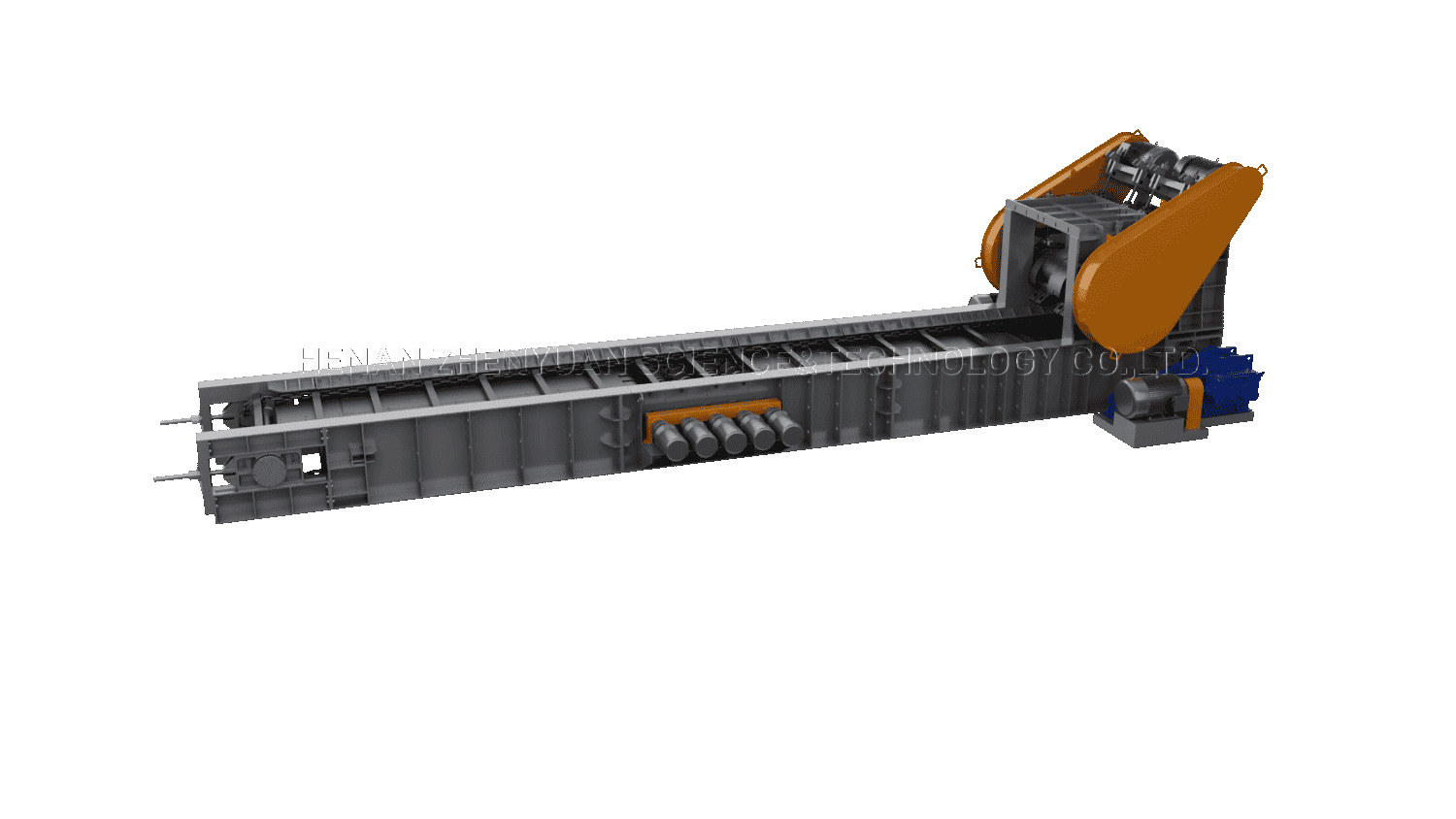

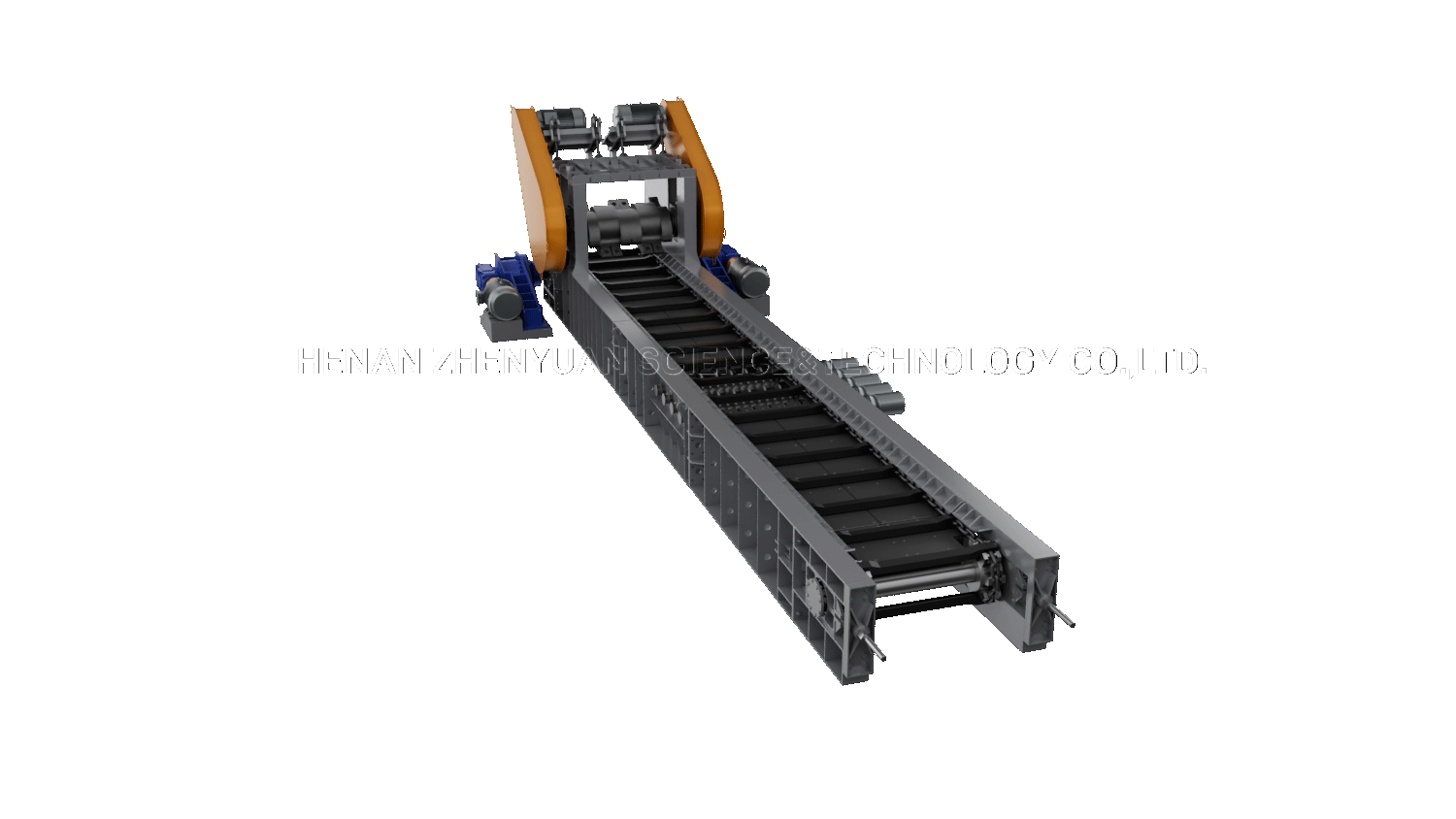

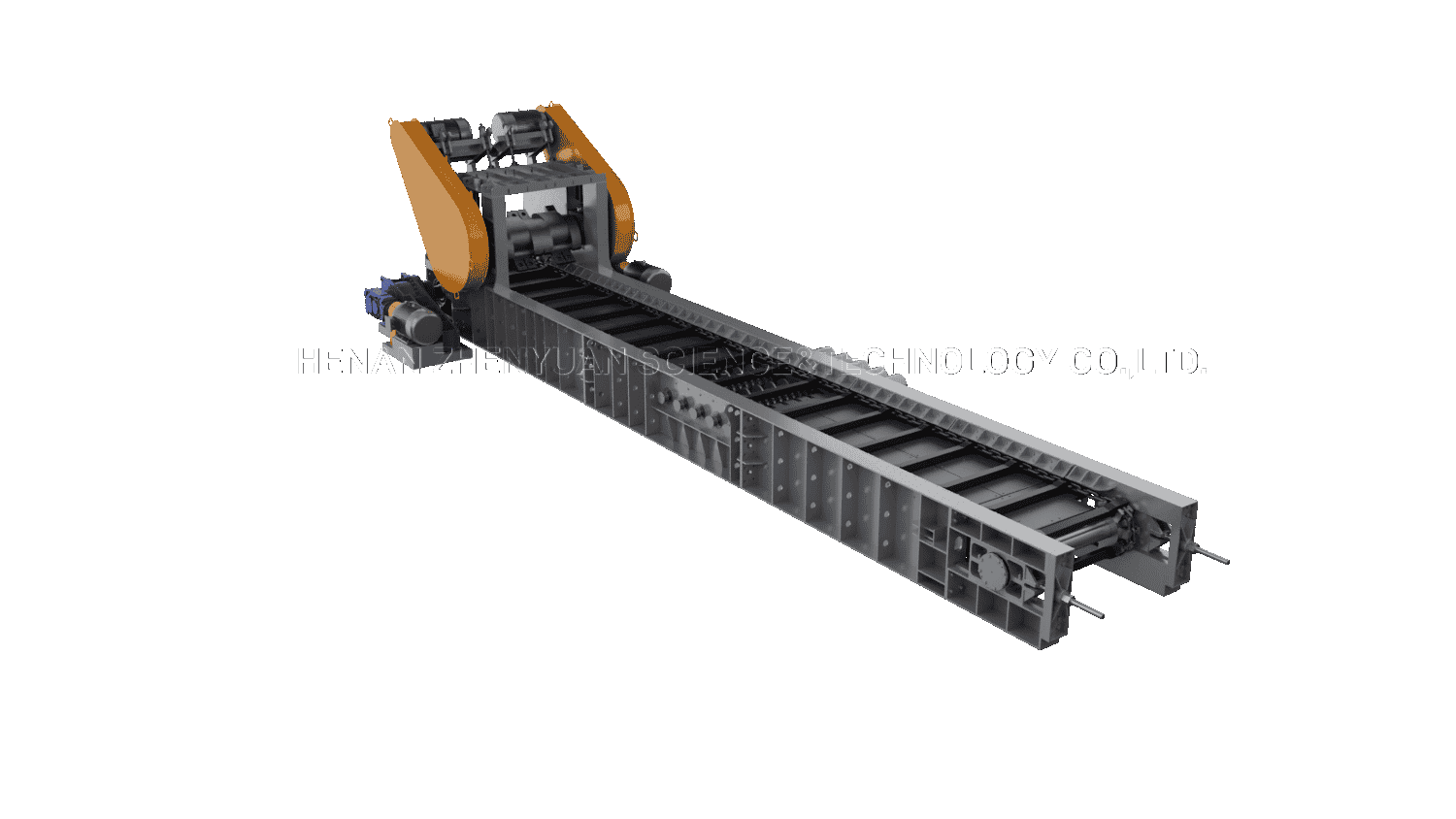

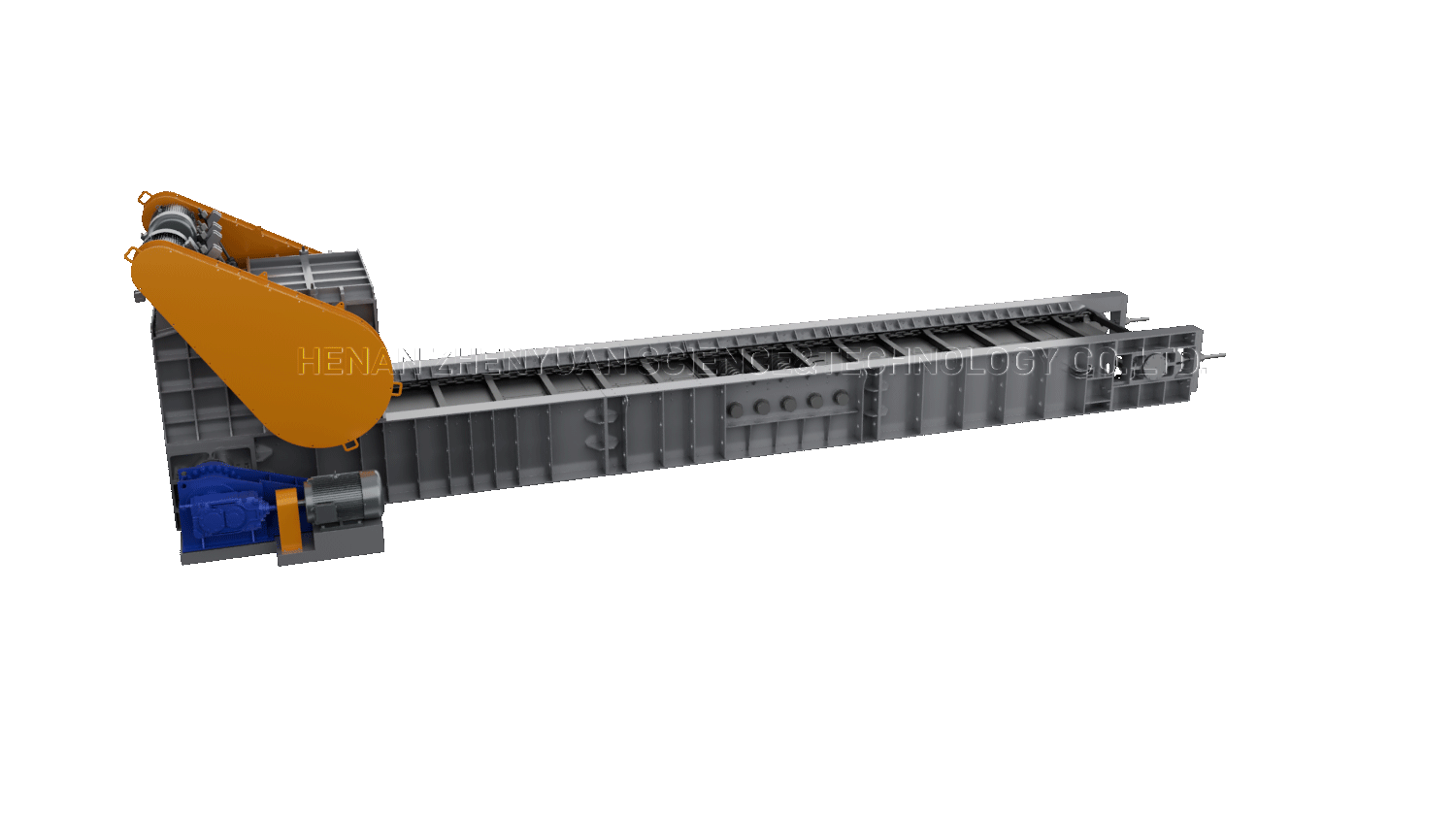

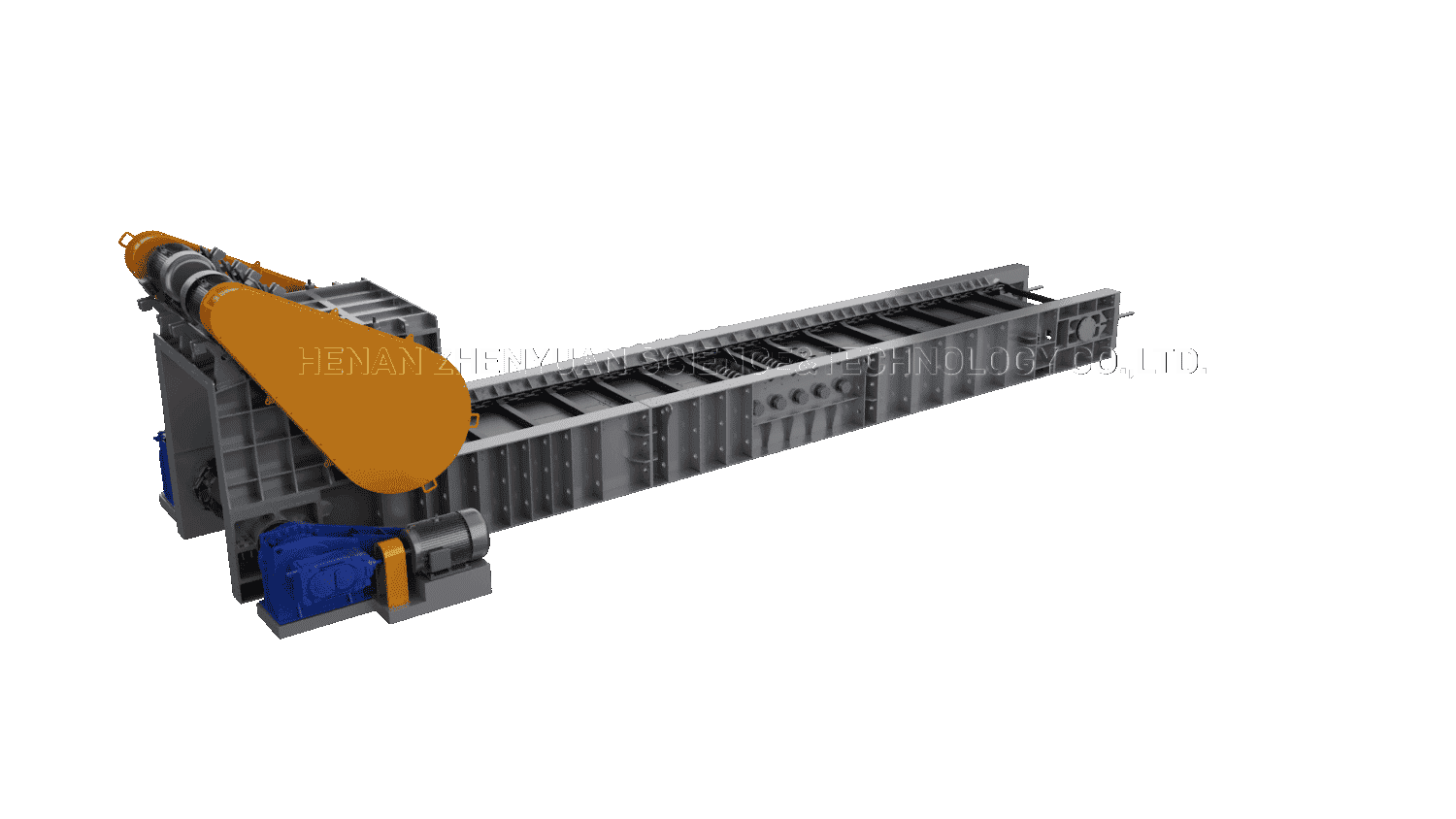

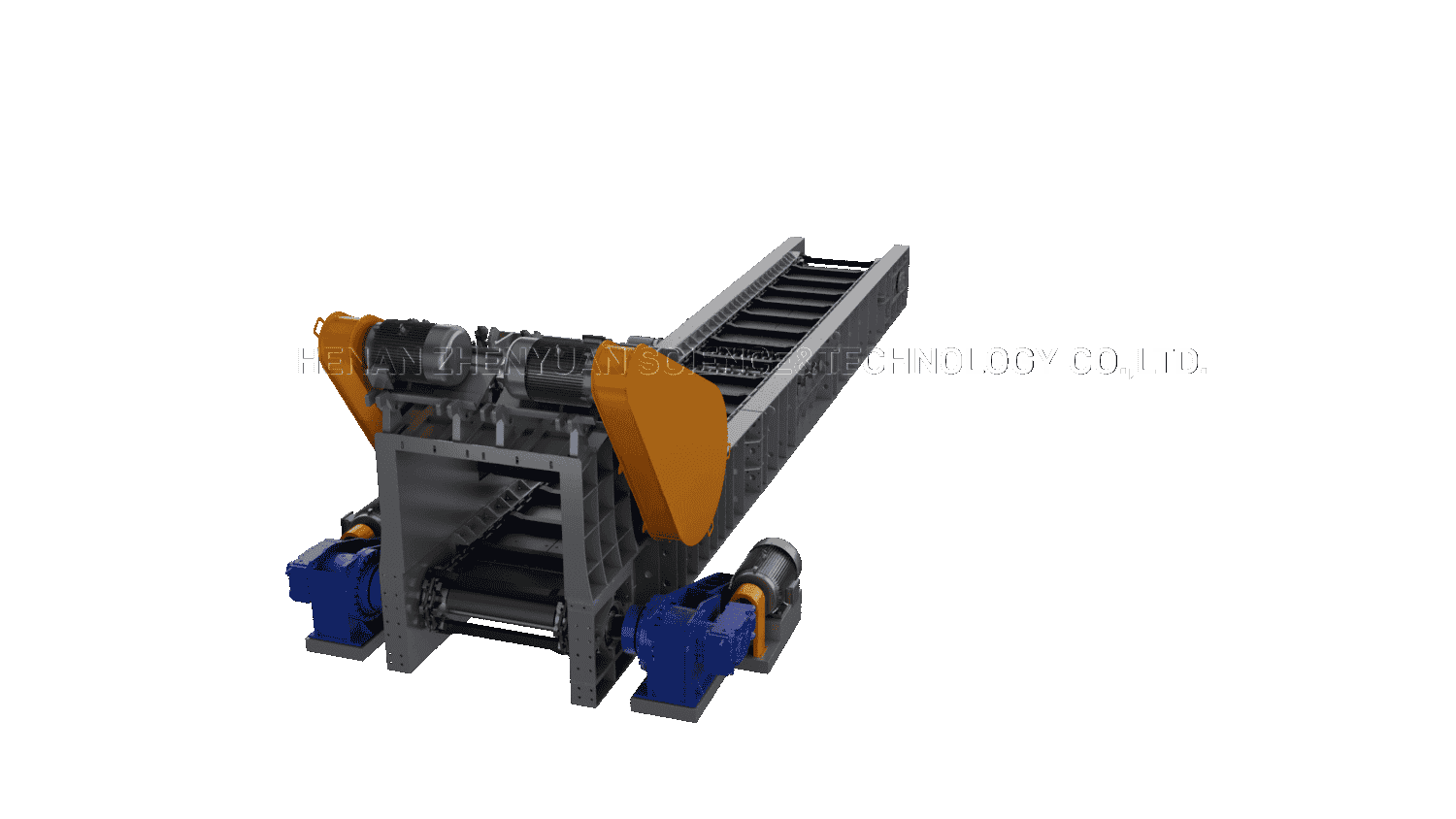

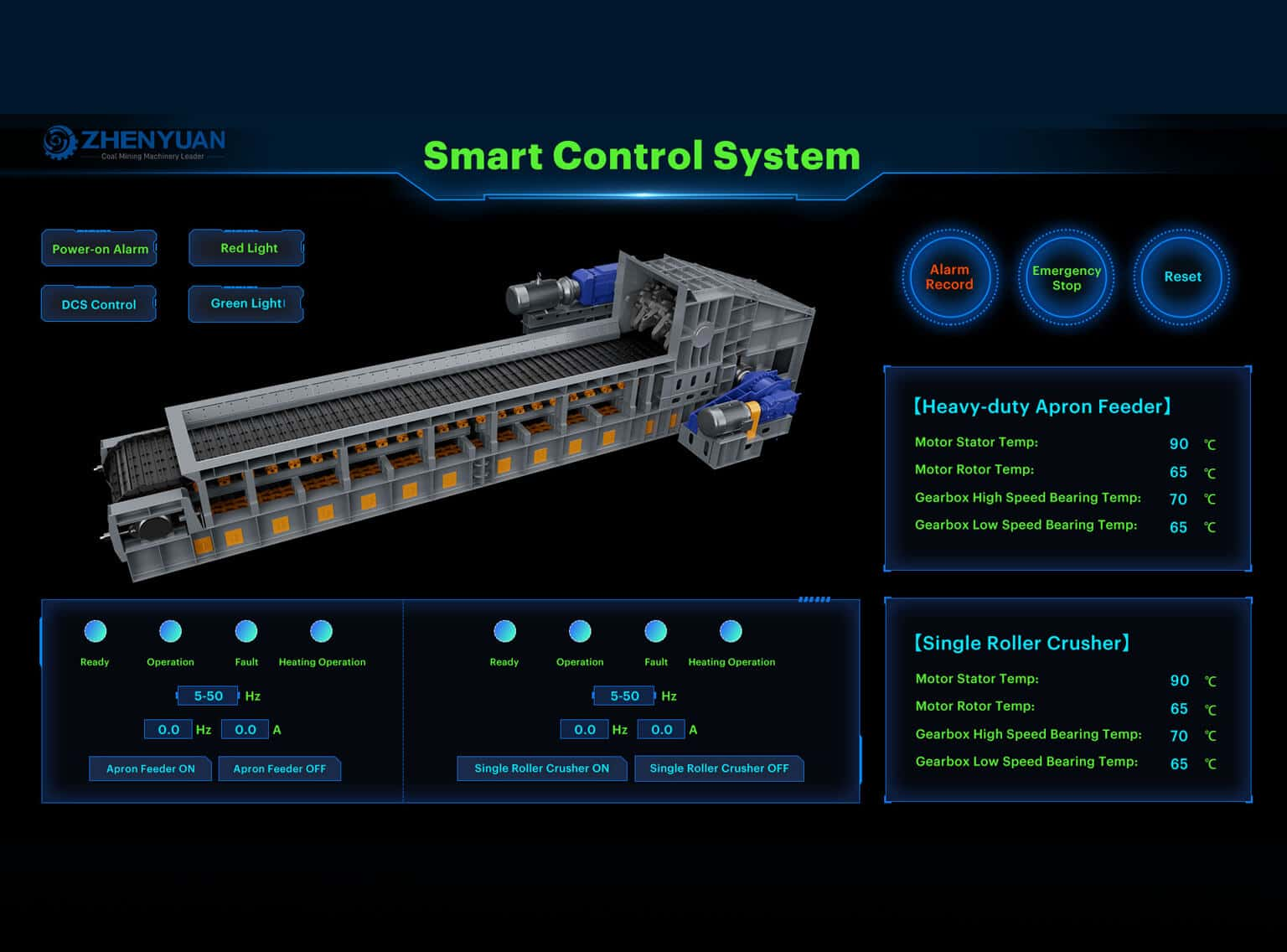

Feeder Breaker is an innovative piece of equipment that integrates material receiving, conveying, screening, crushing, and discharge functions into a single system. The conveying section can be optionally equipped with an apron plate or chain plate structure, and the crushing section is compatible with hammer-type or roller-type configurations. Customizable combinations based on material characteristics and production needs.

Feeder Breaker primarily utilizes a motor-driven chain conveyor to uniformly feed materials into the crushing zone, where the teeth roller activates high-strength wear-resistant crushing teeth to apply compressive, shearing, and tearing forces to the materials.

The compact design with a lower feeding height and horizontal material flow technology enables the feeder breaker to be widely applied in open-pit mines.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Capacity |

Average Input Size |

Inlet Port Size |

Output Finished Product Size |

|

Coal(t/h) |

H*W*L(mm) |

H*W(mm) |

(mm) |

|

|

TP12 |

500-1000 |

800*950*∞ |

1790*1350 |

95%<200 |

|

TP14 |

1000-1500 |

1000*1400*∞ |

1790*1550 |

95%<300 |

|

TP16 |

1500-2000 |

1200*1600*∞ |

1790*1750 |

95%<300 |

|

TP18 |

2000-2500 |

1200*1800*∞ |

1790*1950 |

95%<300 |

|

TP20 |

2500-3000 |

1400*2000*∞ |

1790*2150 |

95%<300 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-120mm

Capacity: 2000-2500TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-300mm

Capacity:1000-1200TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-30mm, 30-80mm, 80-140mm, 140-300mm

Capacity:1500TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-50mm

Capacity: 2500-3000TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-50mm

Capacity: 1500-1800TPH

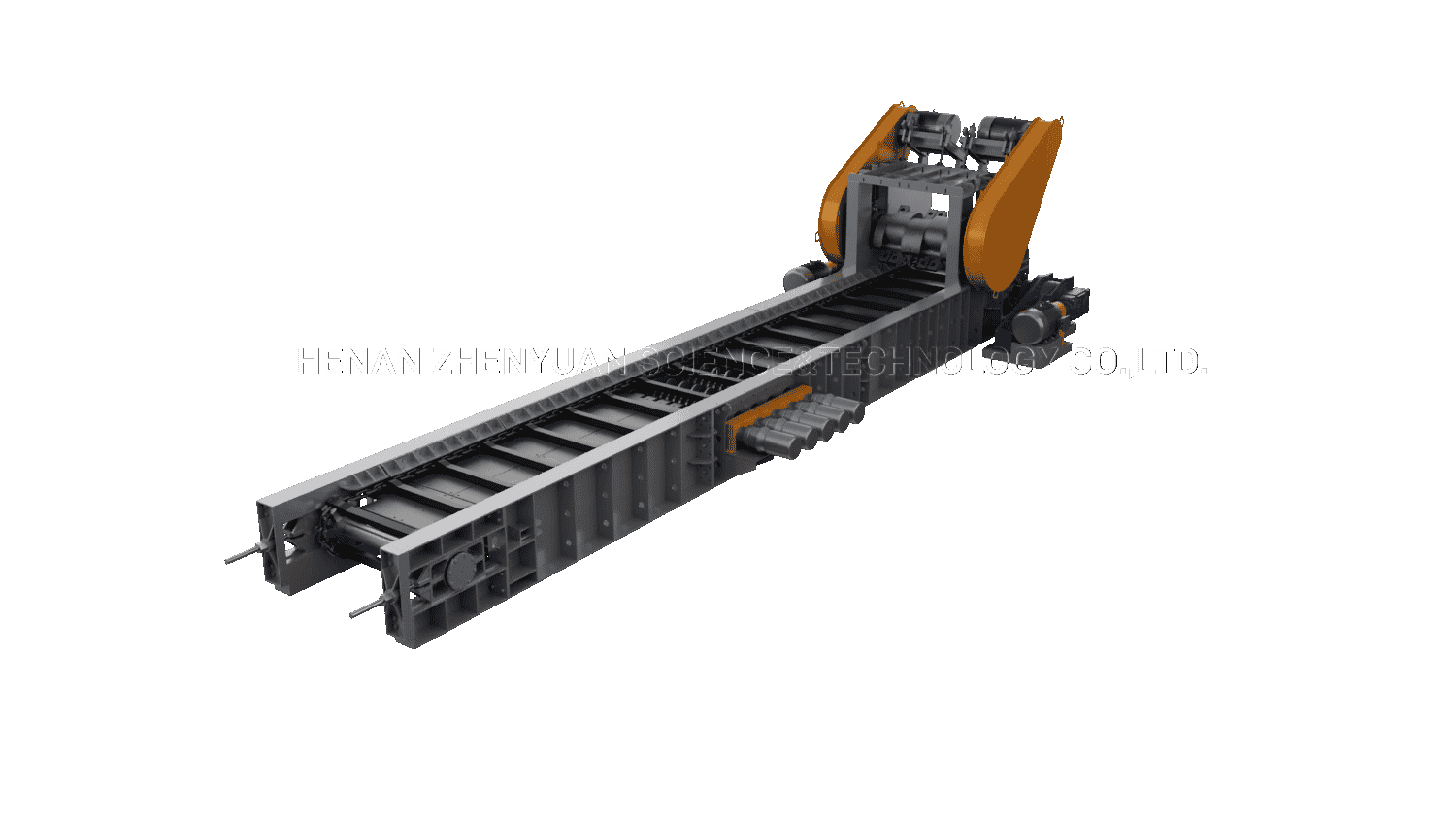

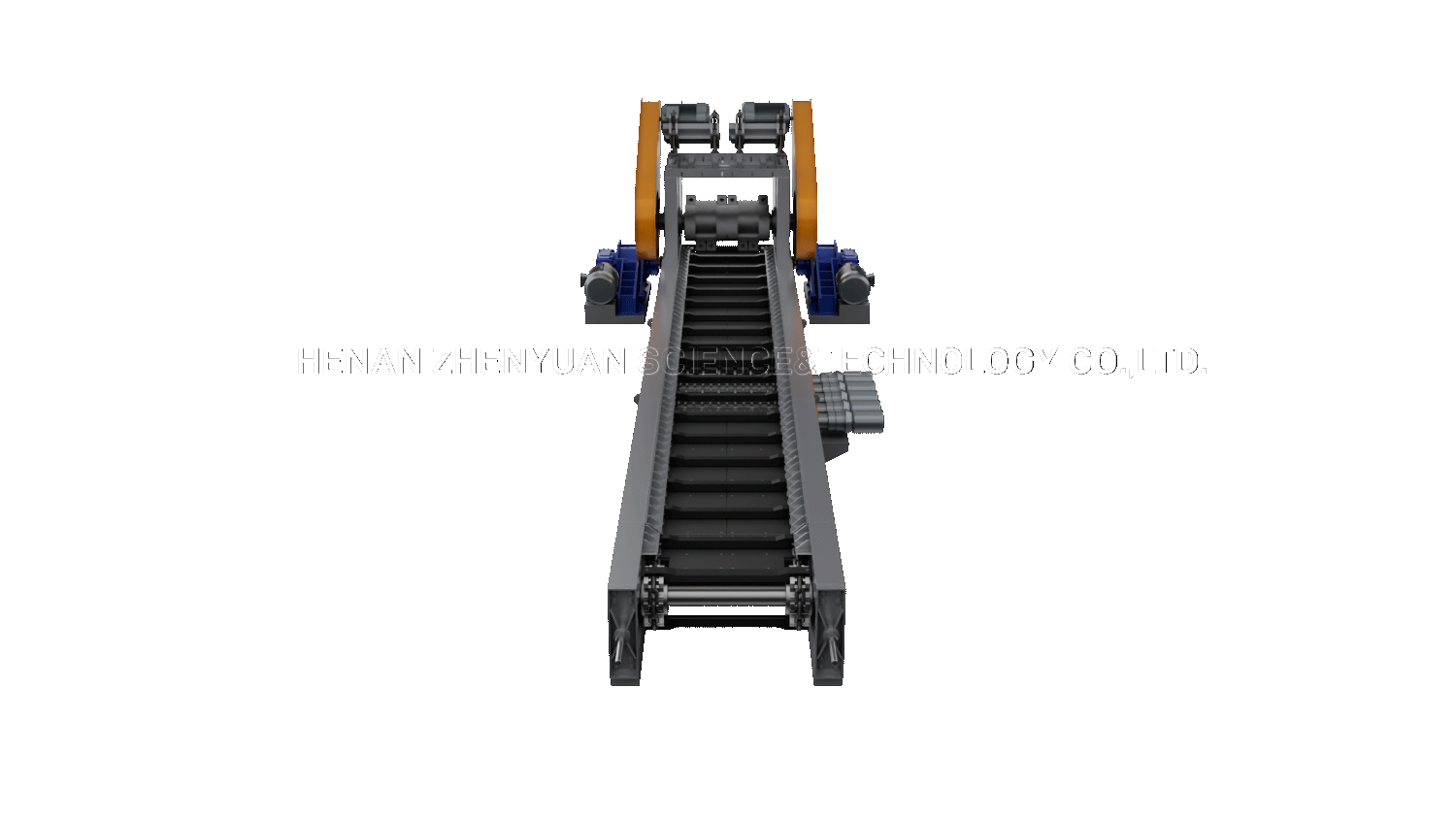

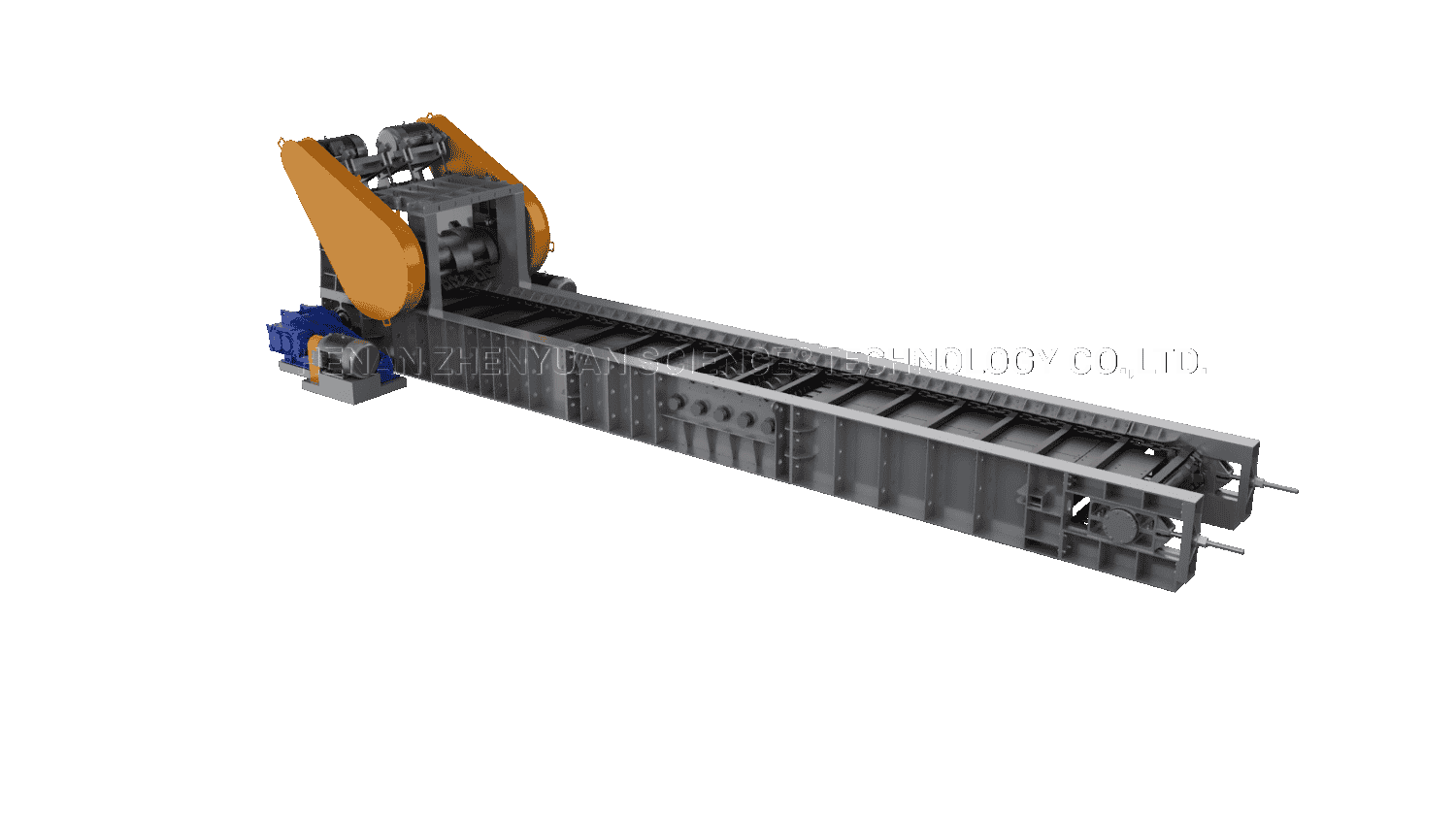

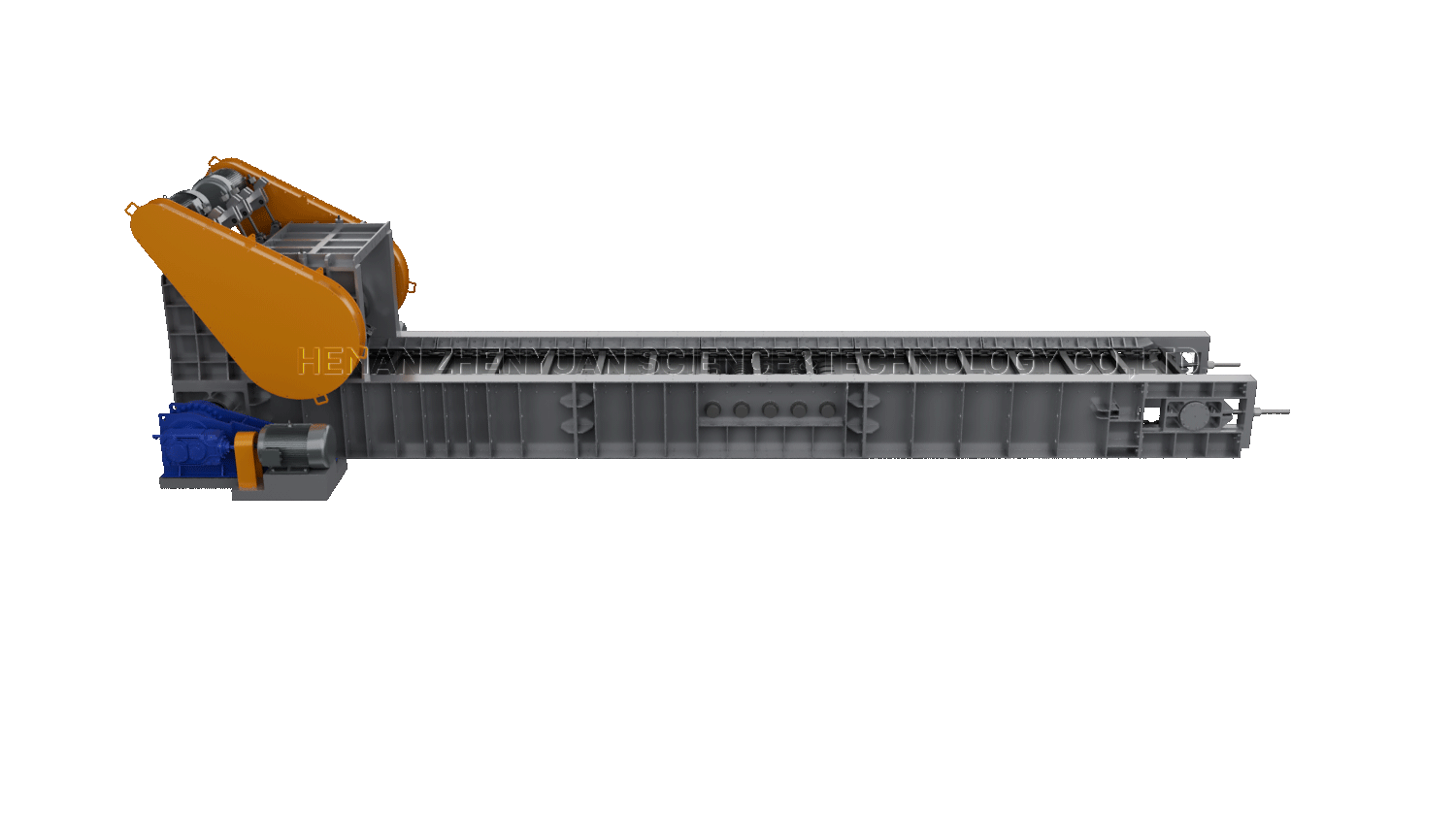

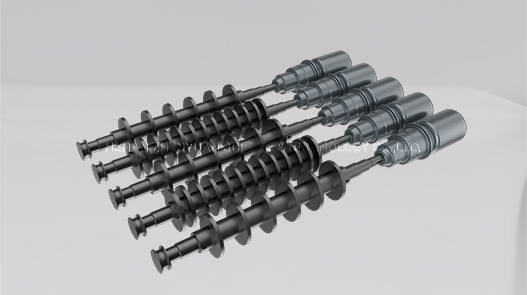

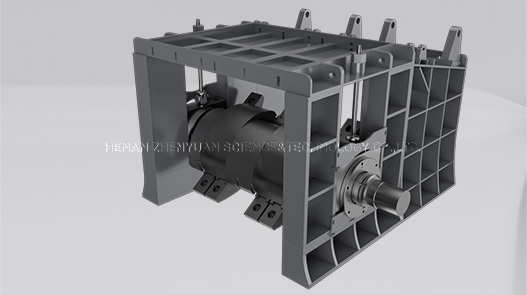

Roller Shaft Assembly

Scraper Bar

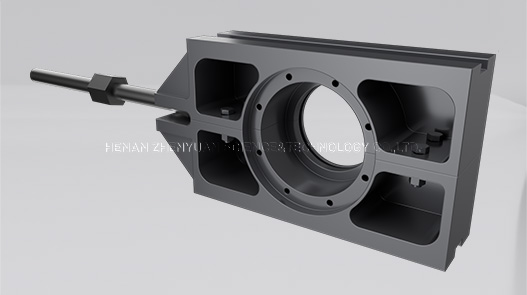

Tension Device

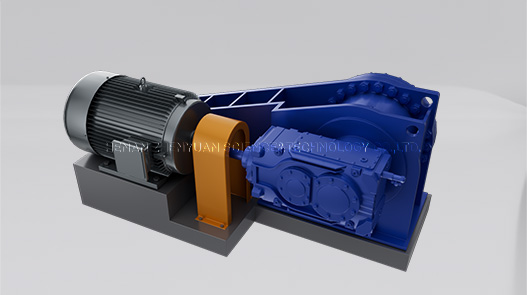

Feeder Driving Device

Breaker Driving Device

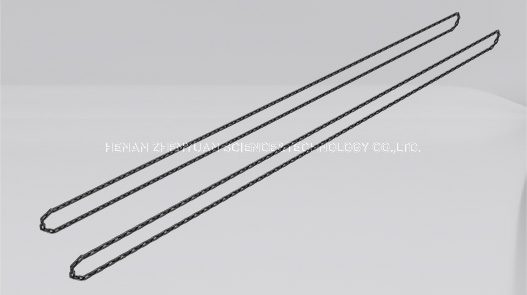

Feeder Chain

Breaker Assembly