Strong crusher power and high crushing ratio, without over-crushed phenomenon

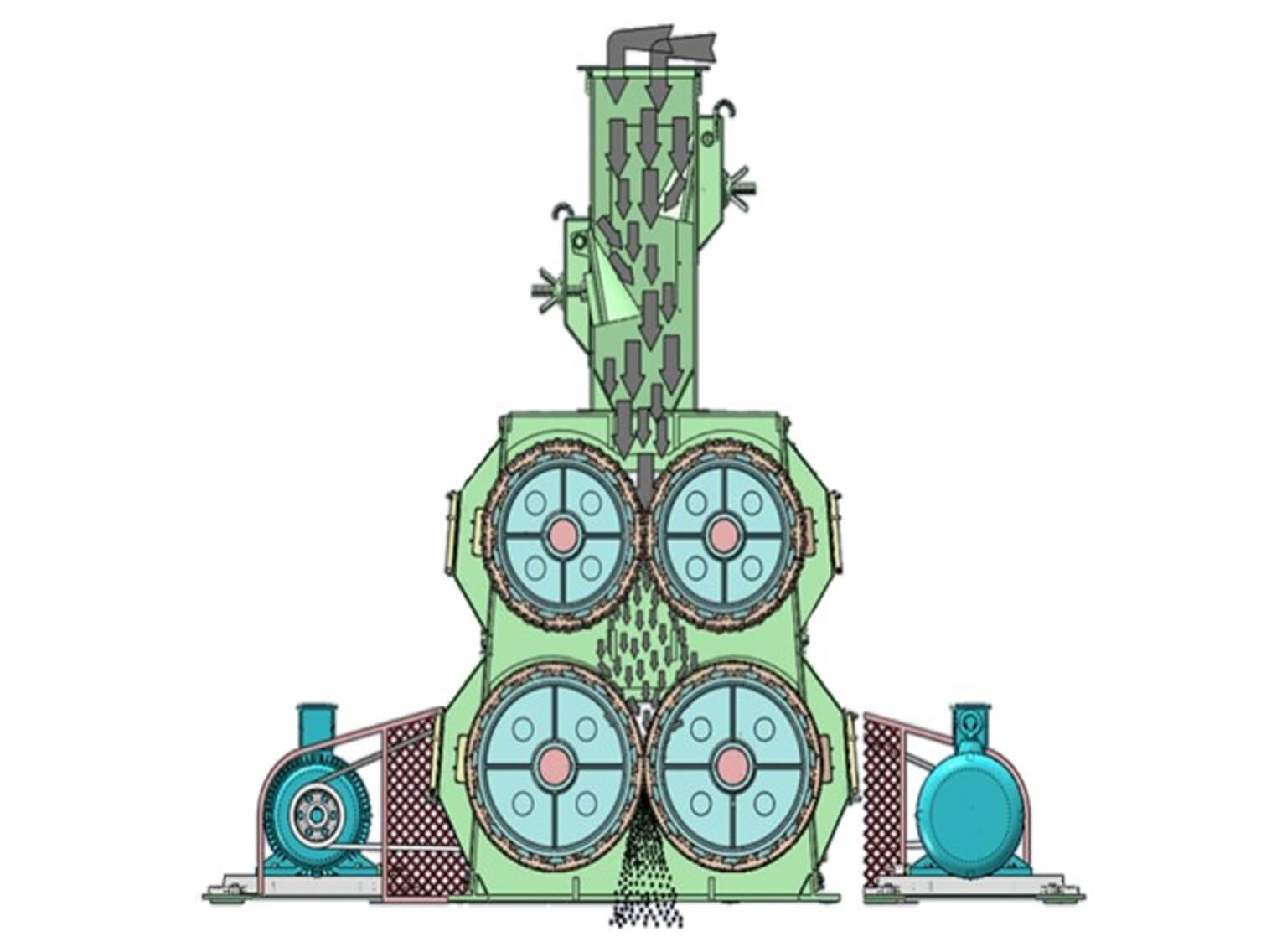

Crushing grades have primary, secondary and tertiary crushing

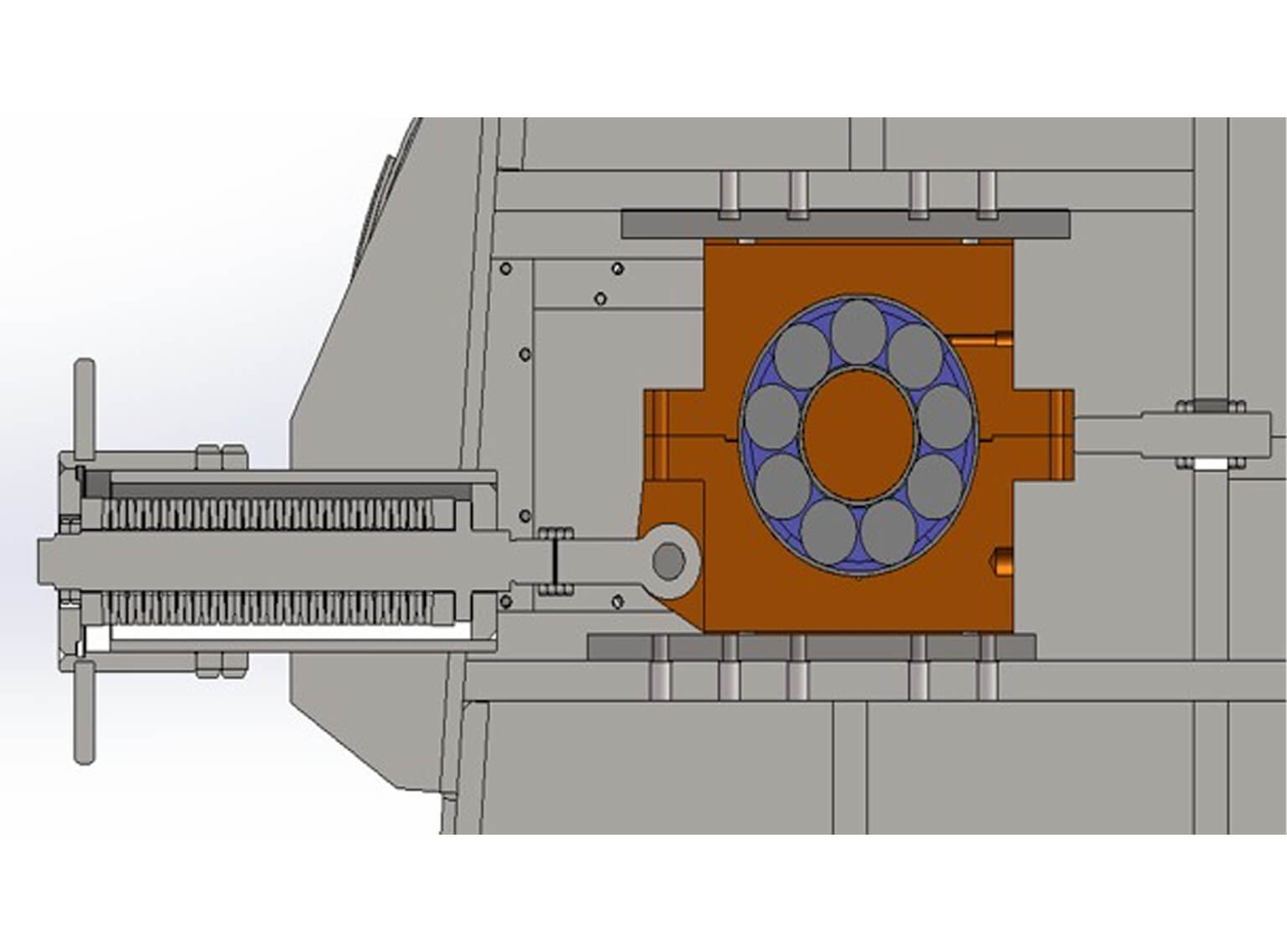

High strength alloy steel shafts

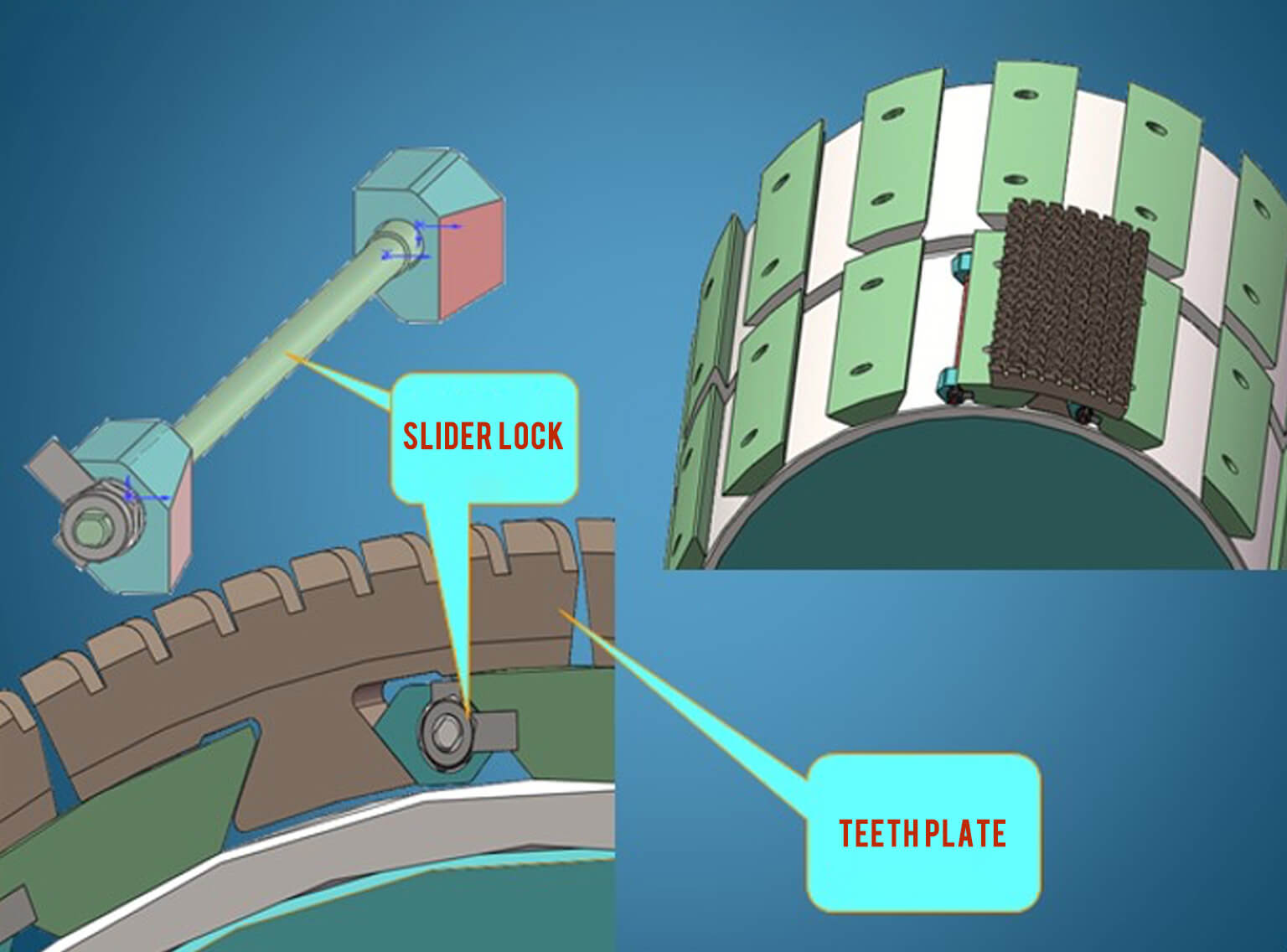

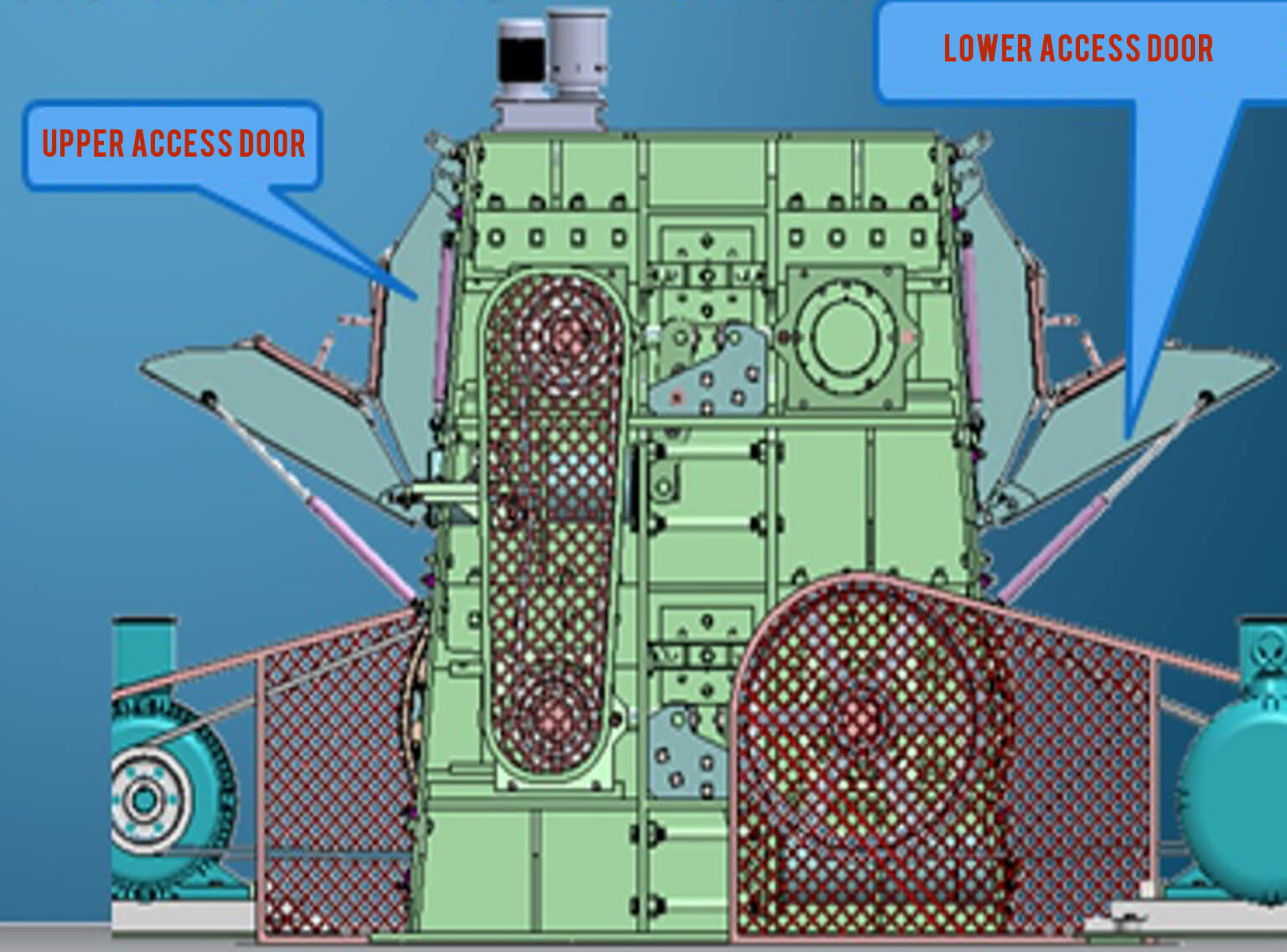

Replaceable wear part design, teeth roller and teeth plate can be replaced quickly

Unique tooth designs to allow maximum utilization of the materials

Grease lubricated bearings usually fed by automated system

Automated operation with PLC control system and overload protection system

High efficiency, energy saving, environmental protection, intelligent, non-stick and clog-free.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Max. Input Size (mm) |

Output Size (mm) |

Capacity (tph) |

Power (kw) |

|

ZY4G10-50 |

300 |

0-10 |

50 |

18.5+22 |

|

ZY4G10-70 |

300 |

0-10 |

70 |

2×30 |

|

ZY4G10-90 |

300 |

0-10 |

90 |

37+45 |

|

ZY4G10-100 |

300 |

0-10 |

100 |

2×45 |

|

ZY4G10-140 |

300 |

0-10 |

140 |

45+55 |

|

ZY4G10-150 |

300 |

0-10 |

150 |

2×55 |

|

ZY4G10-170 |

300 |

0-10 |

170 |

55+75 |

|

ZY4G10-200 |

300 |

0-10 |

200 |

75+90 |

|

ZY4G10-250 |

300 |

0-10 |

250 |

90+110 |

|

ZY4G10-300 |

300 |

0-10 |

300 |

2×110 |

|

ZY4G10-350 |

300 |

0-10 |

350 |

110+132 |

|

ZY4G10-400 |

300 |

0-10 |

400 |

2×160 |

|

ZY4G10-450 |

300 |

0-10 |

450 |

160+185 |

|

ZY4G10-500 |

300 |

0-10 |

500 |

185+200 |

|

ZY4G10-550 |

300 |

0-10 |

550 |

2×200 |

|

ZY4G10-600 |

300 |

0-10 |

600 |

2×250 |

|

ZY4G10-650 |

300 |

0-10 |

650 |

250+280 |

|

ZY4G10-700 |

300 |

0-10 |

700 |

2×280 |

|

ZY4G10-800 |

300 |

0-10 |

800 |

280+315 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Lignite Coal/Long Flame Coal

Input Size: 0-1200mm

Output Size: 0-120mm

Capacity: 1000-1200TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-30mm, 30-80mm

Capacity: 2500-3000TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-80mm

Capacity:2000-2500TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-80mm

Capacity:2000-2500TPH

Processing Materials: Raw Coal

Input Size: 0-1500mm

Output Size: 0-300mm

Capacity: 3500-4000TPH