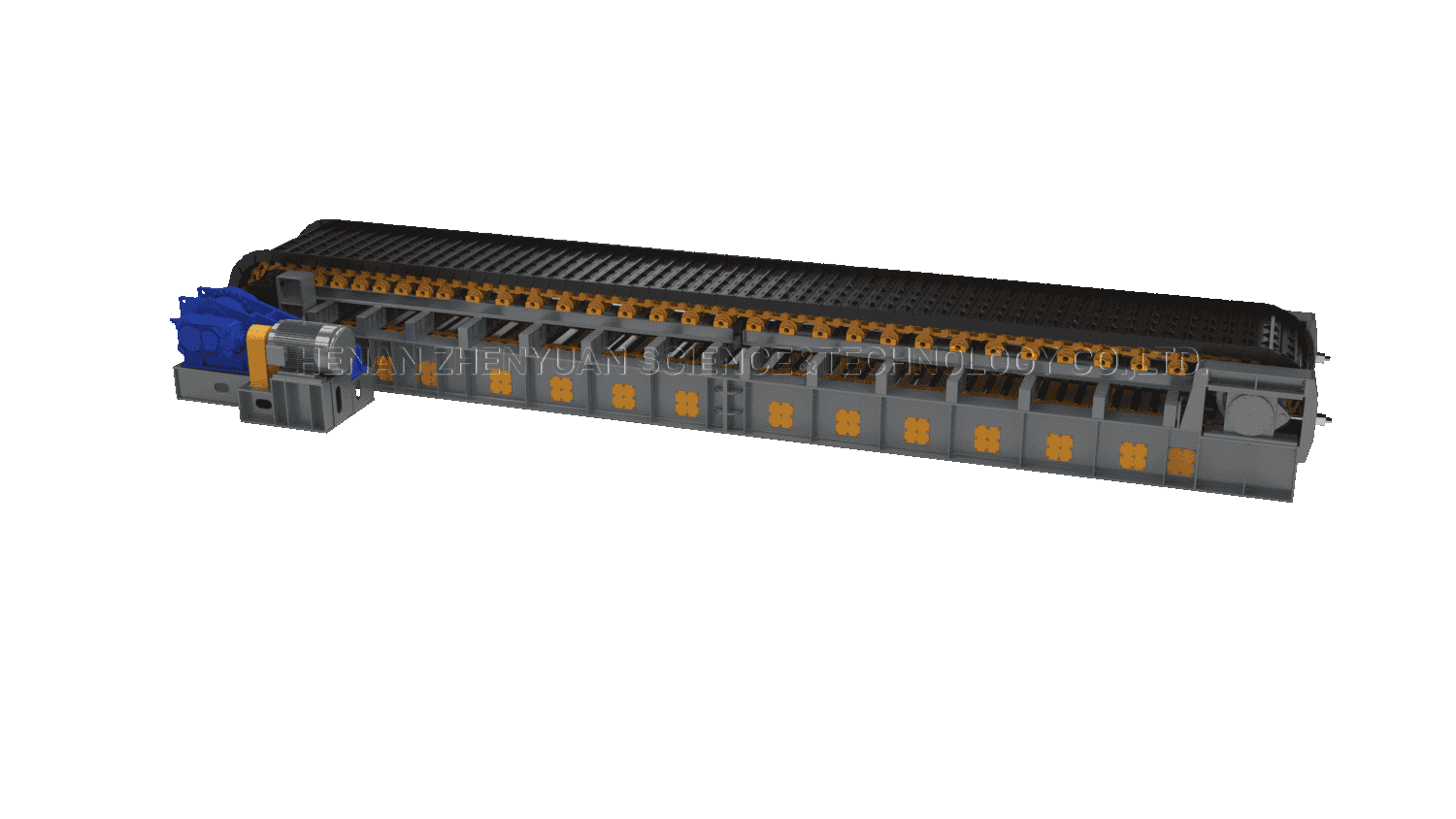

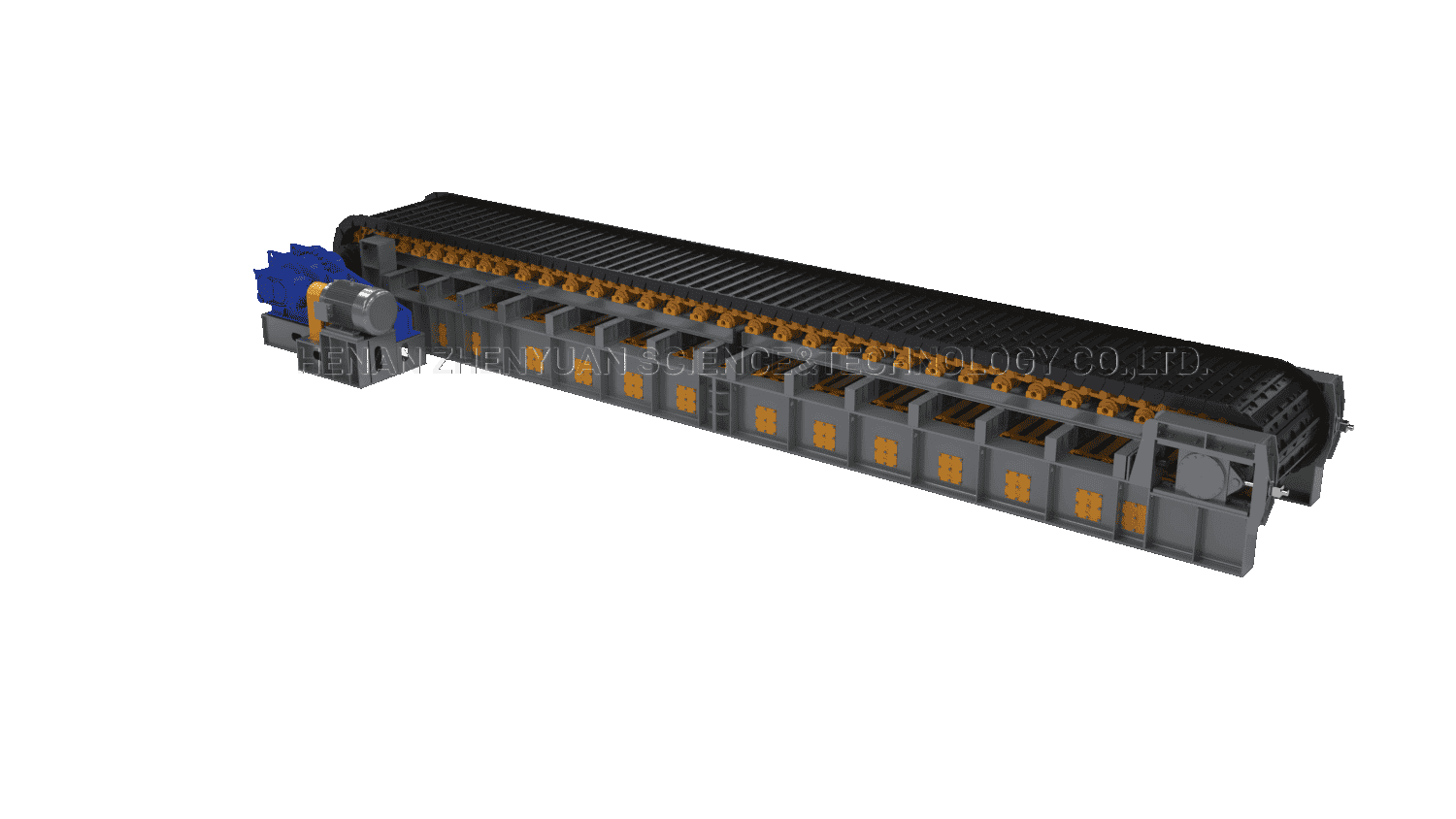

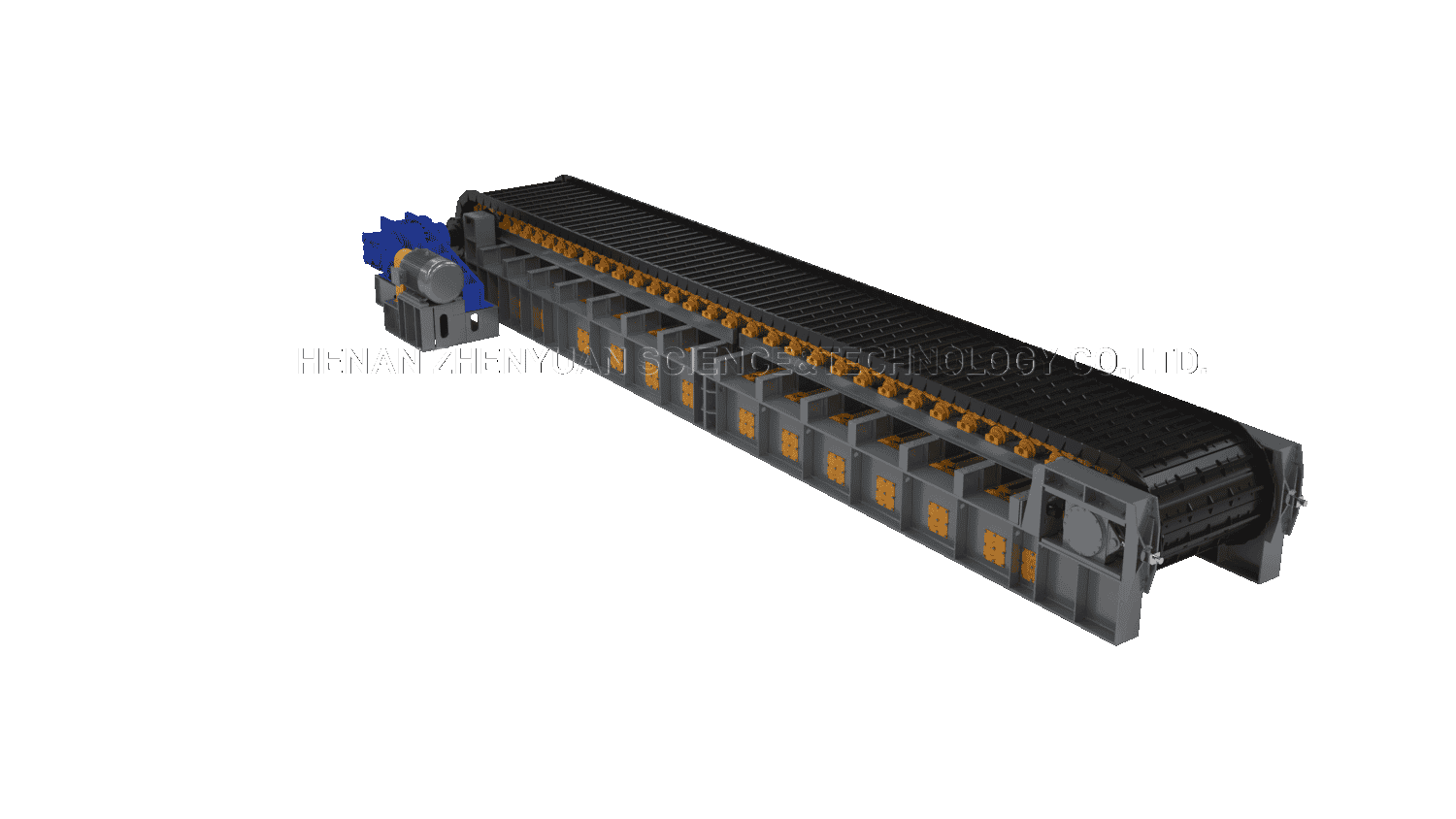

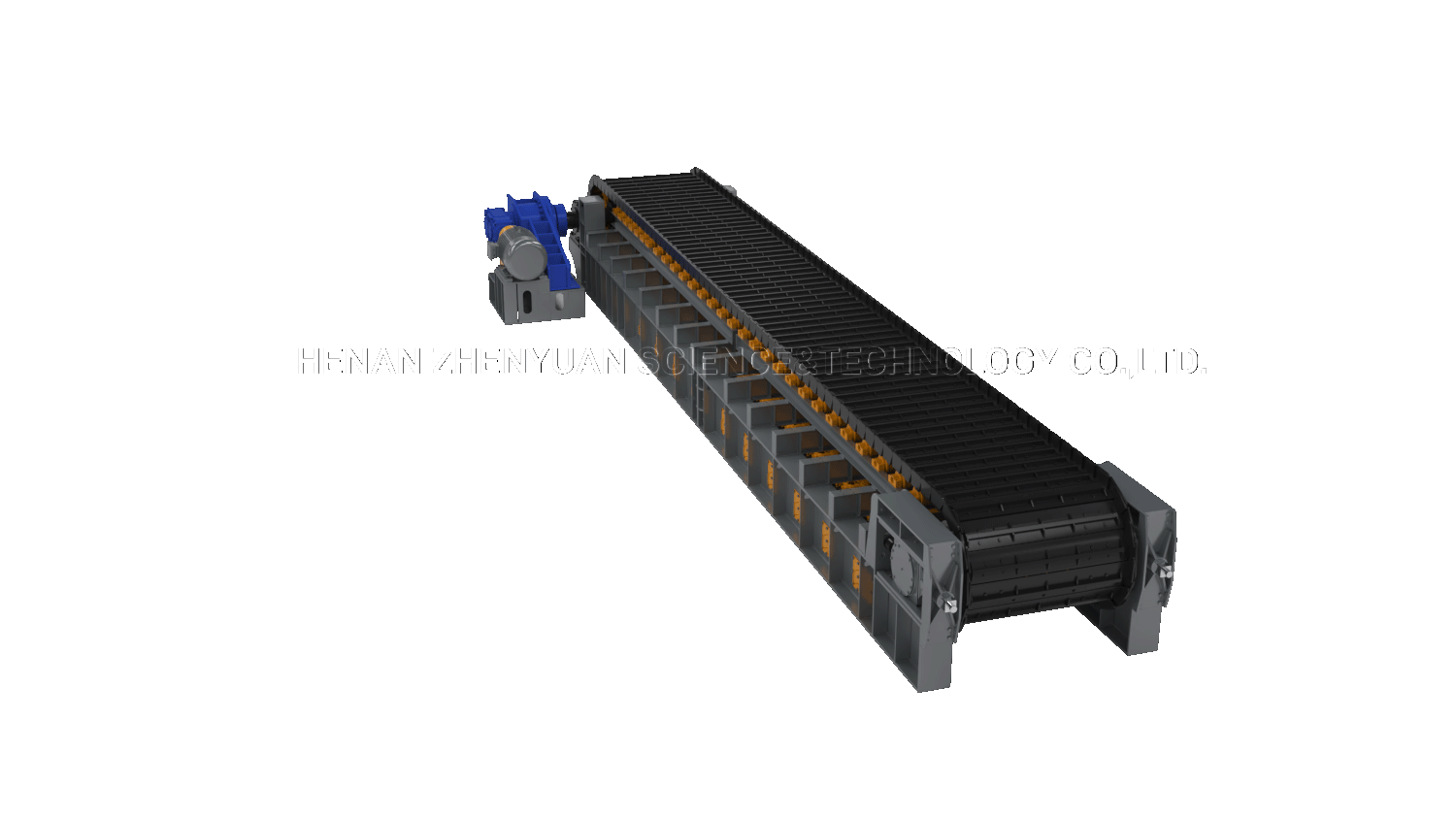

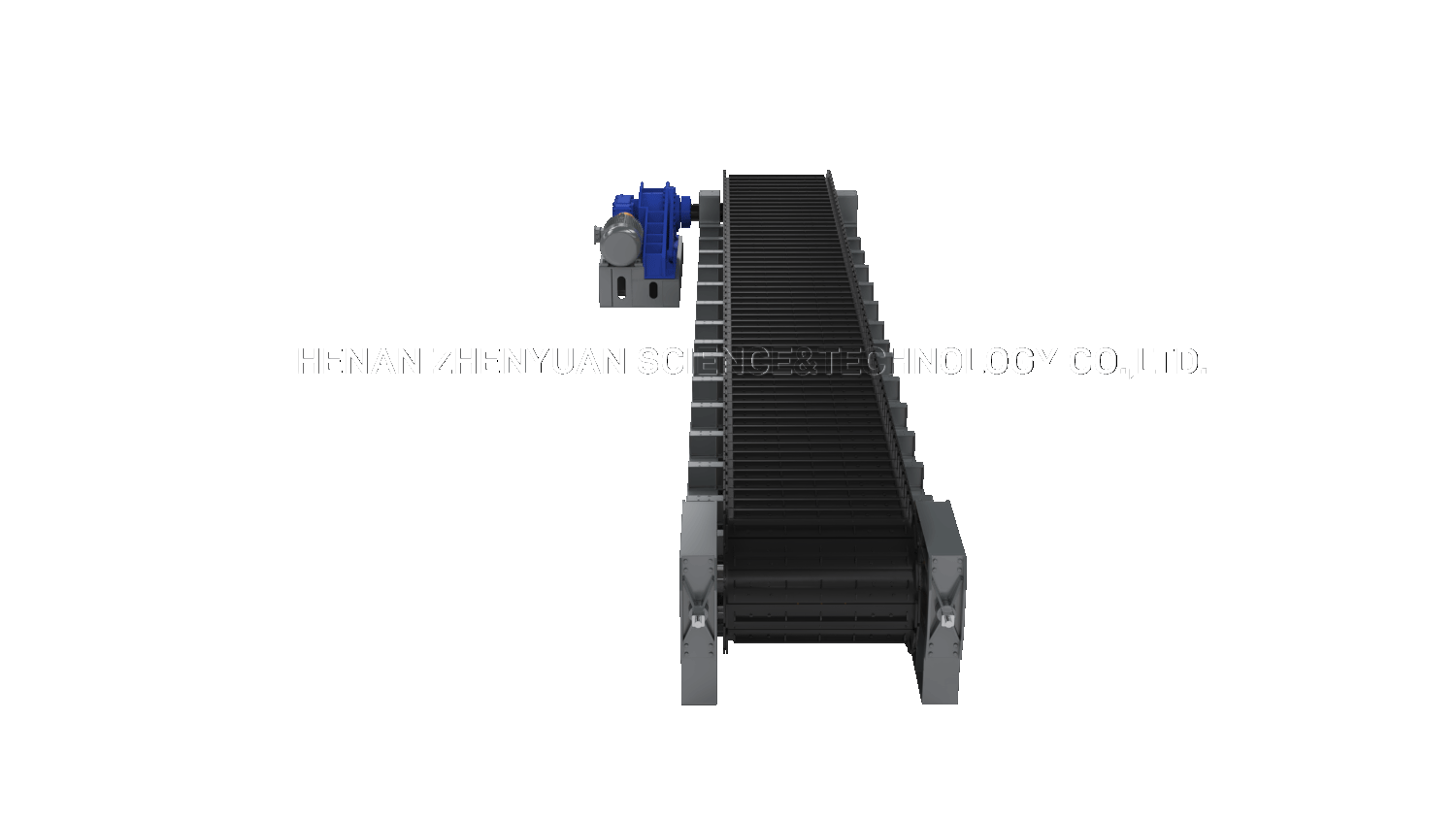

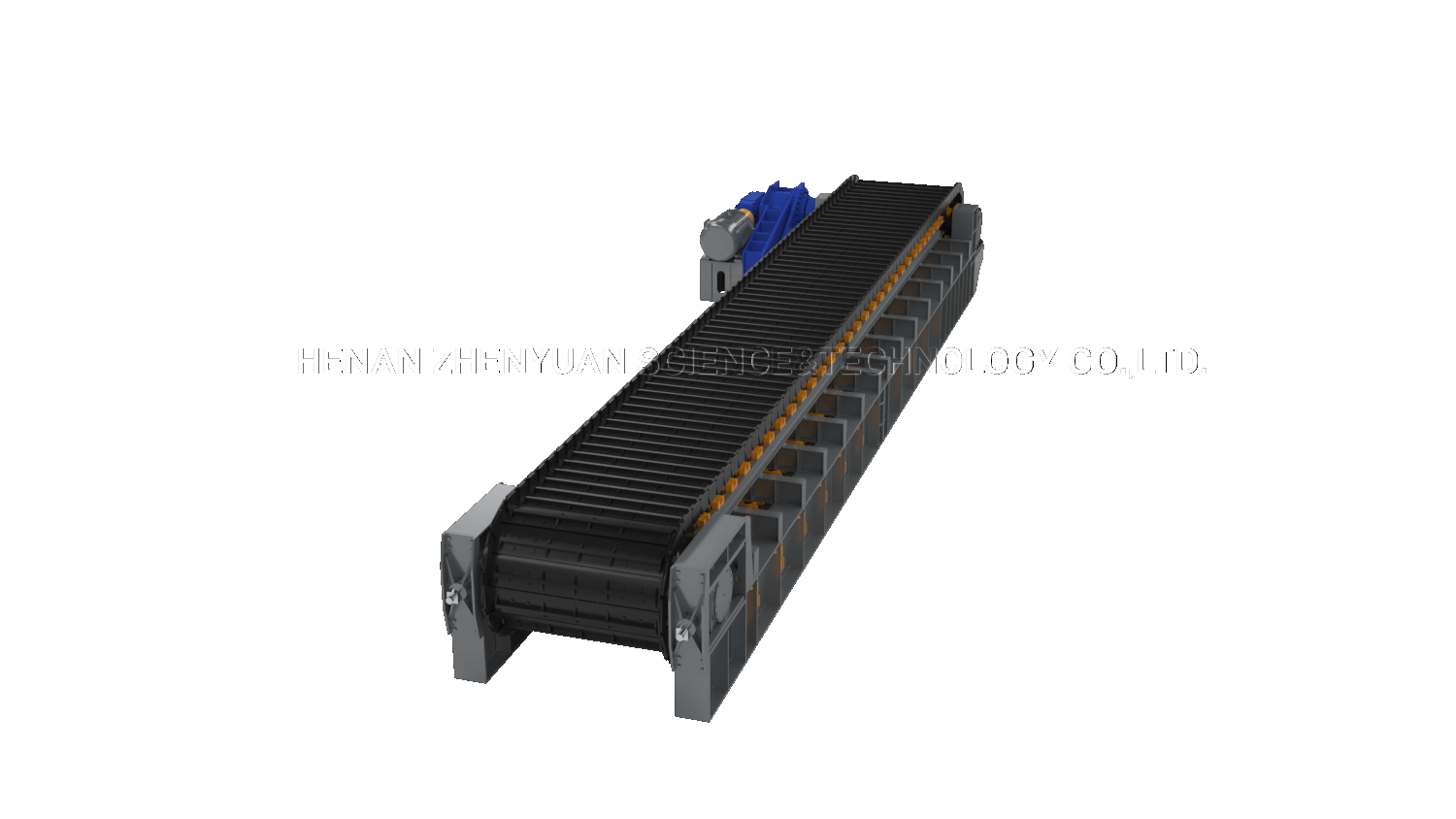

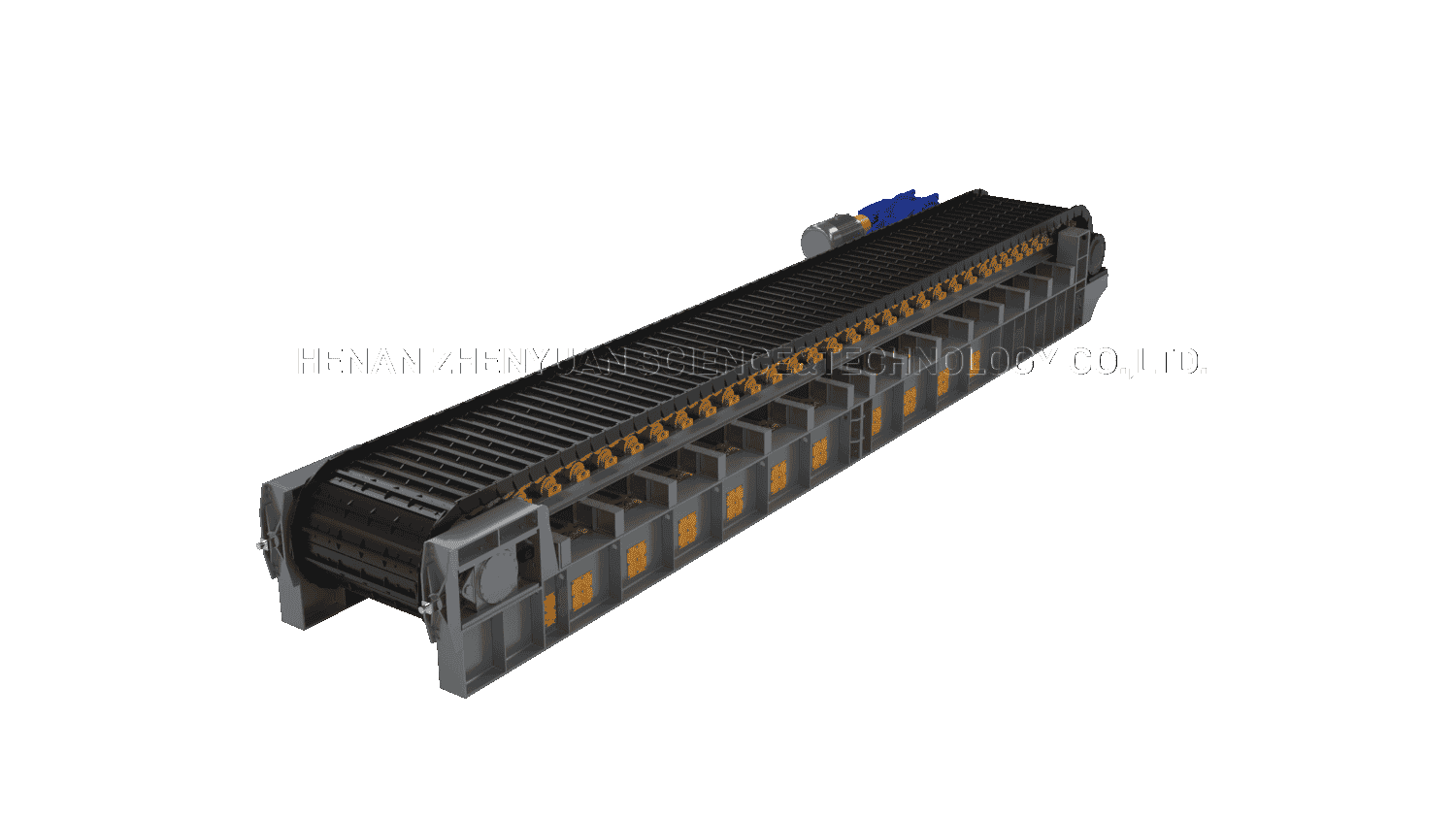

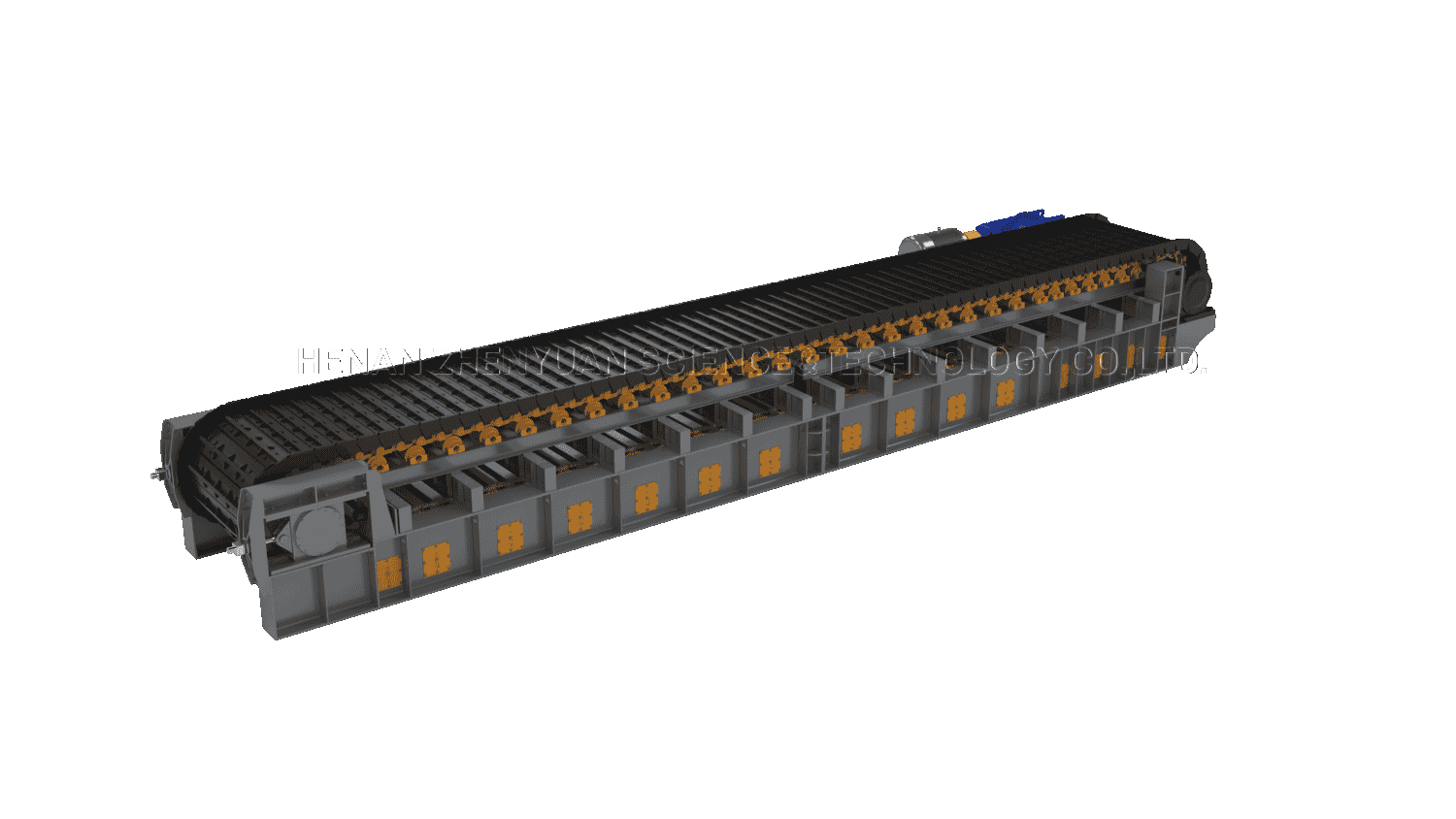

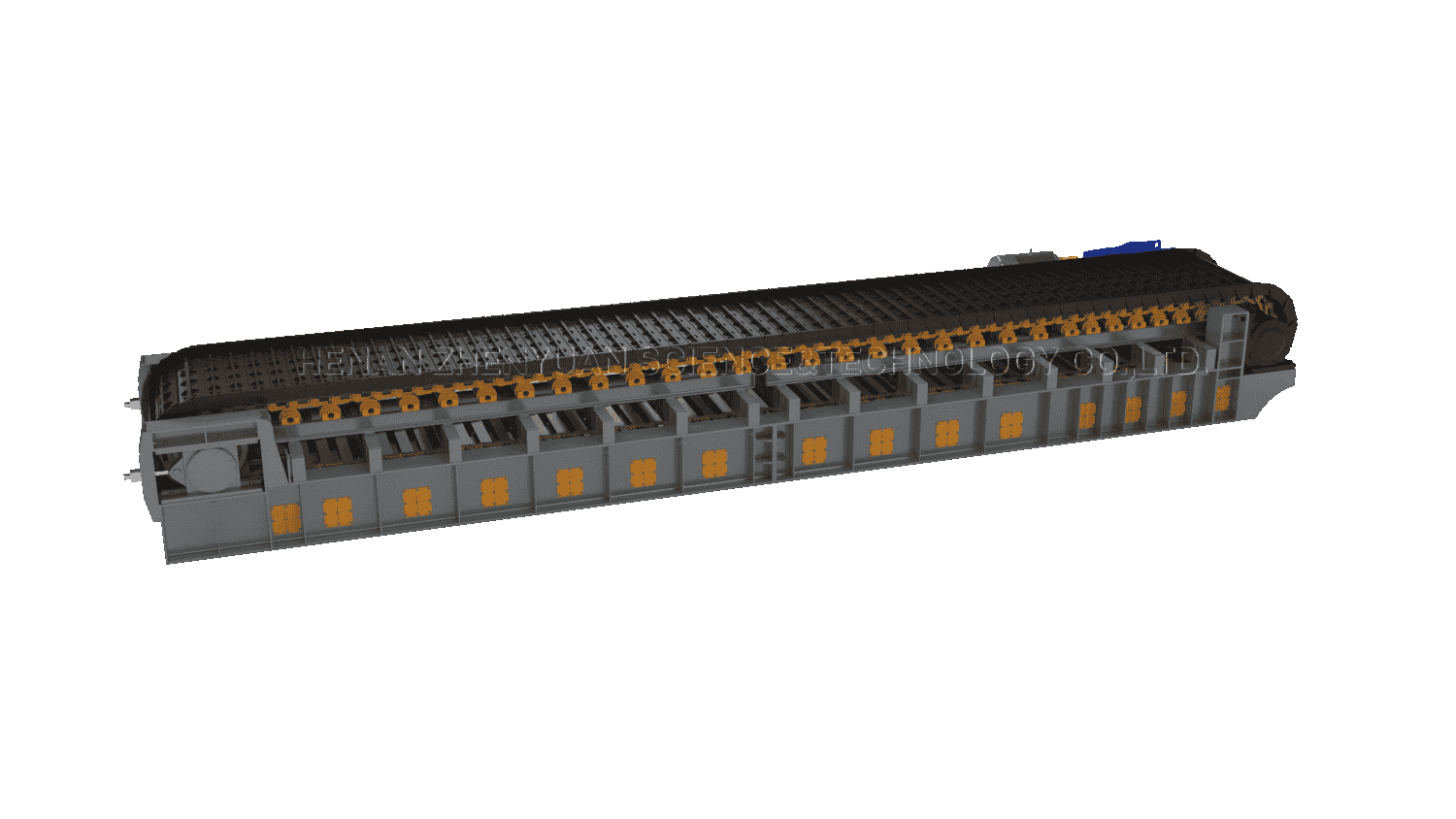

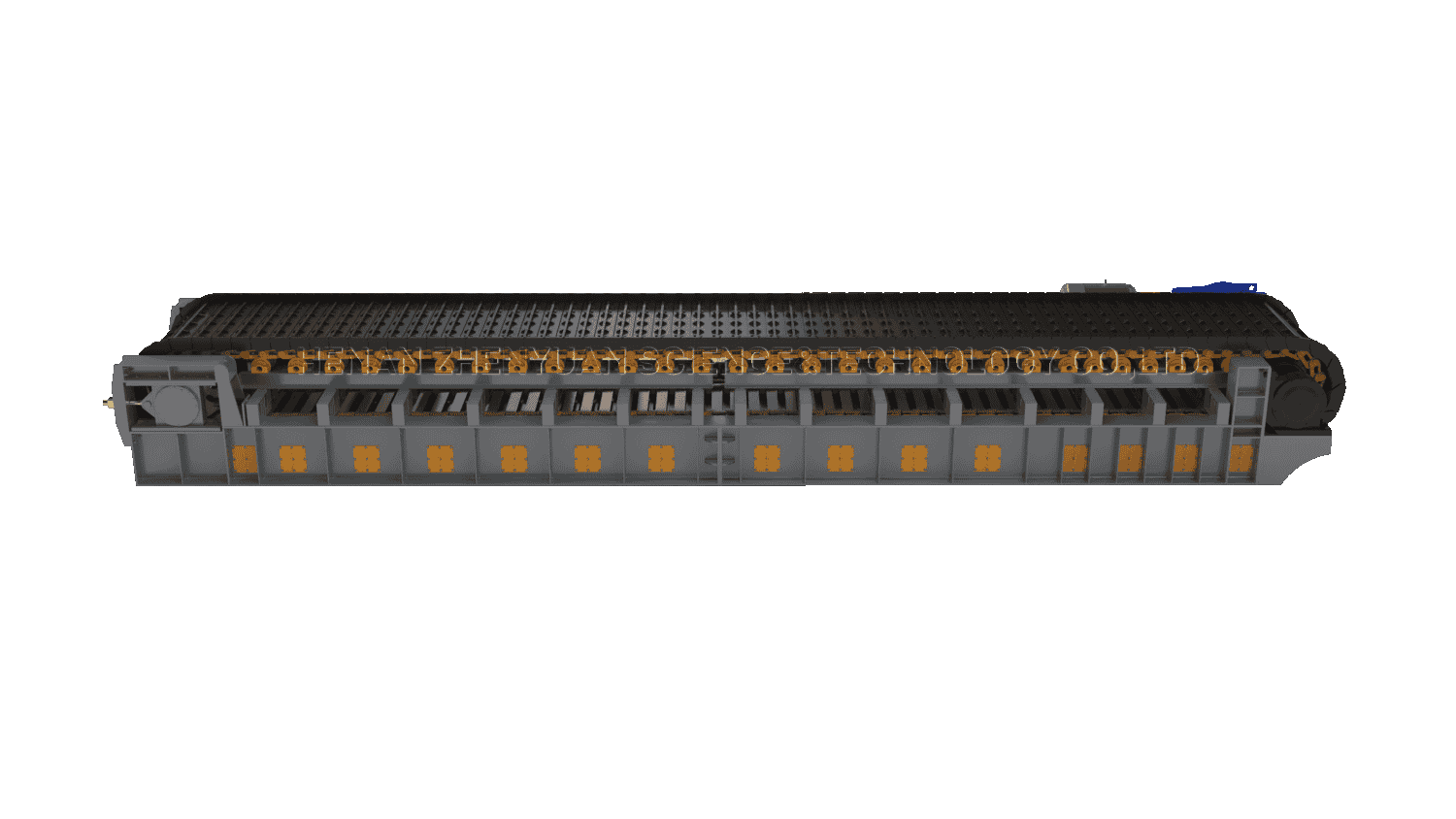

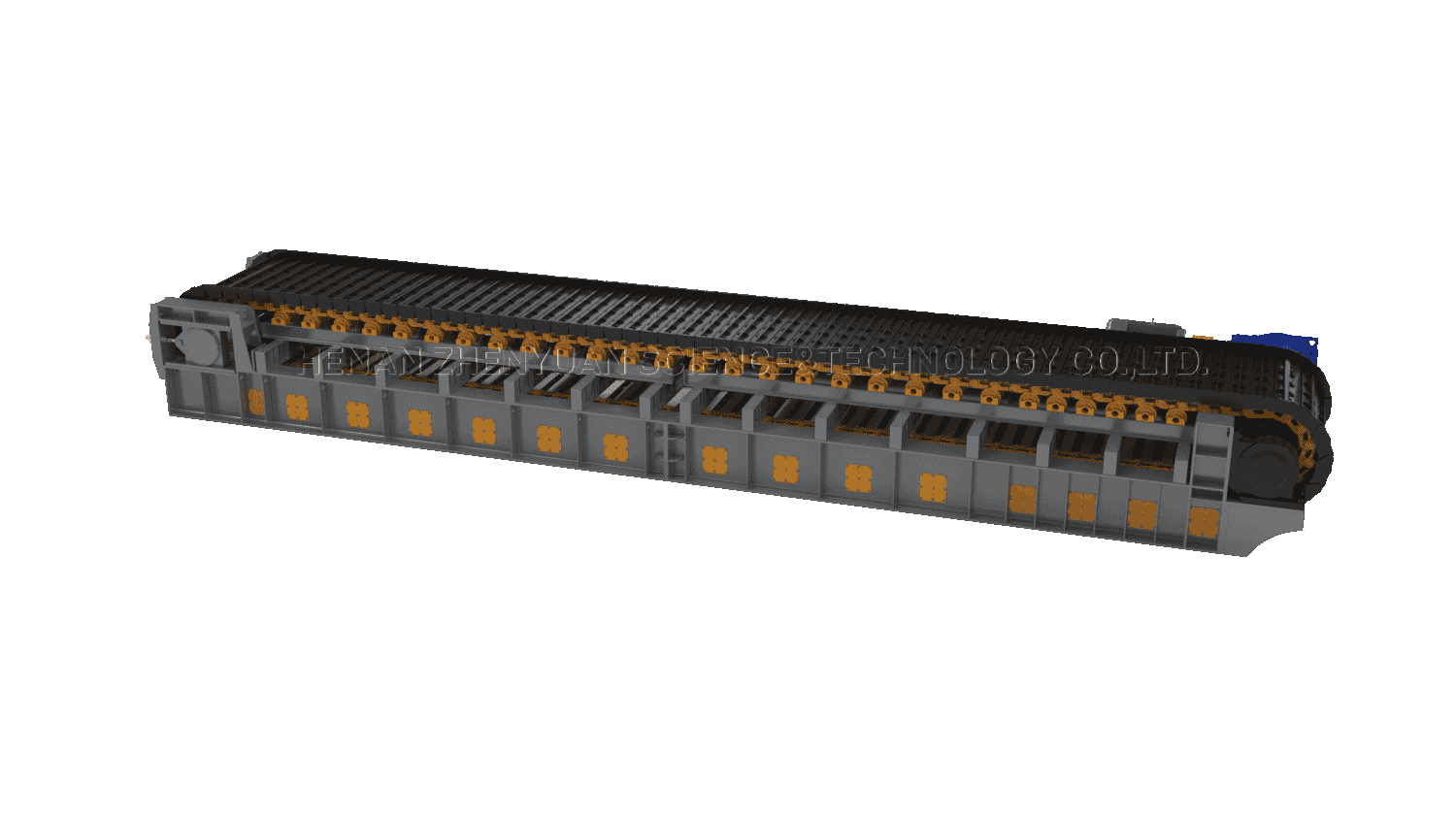

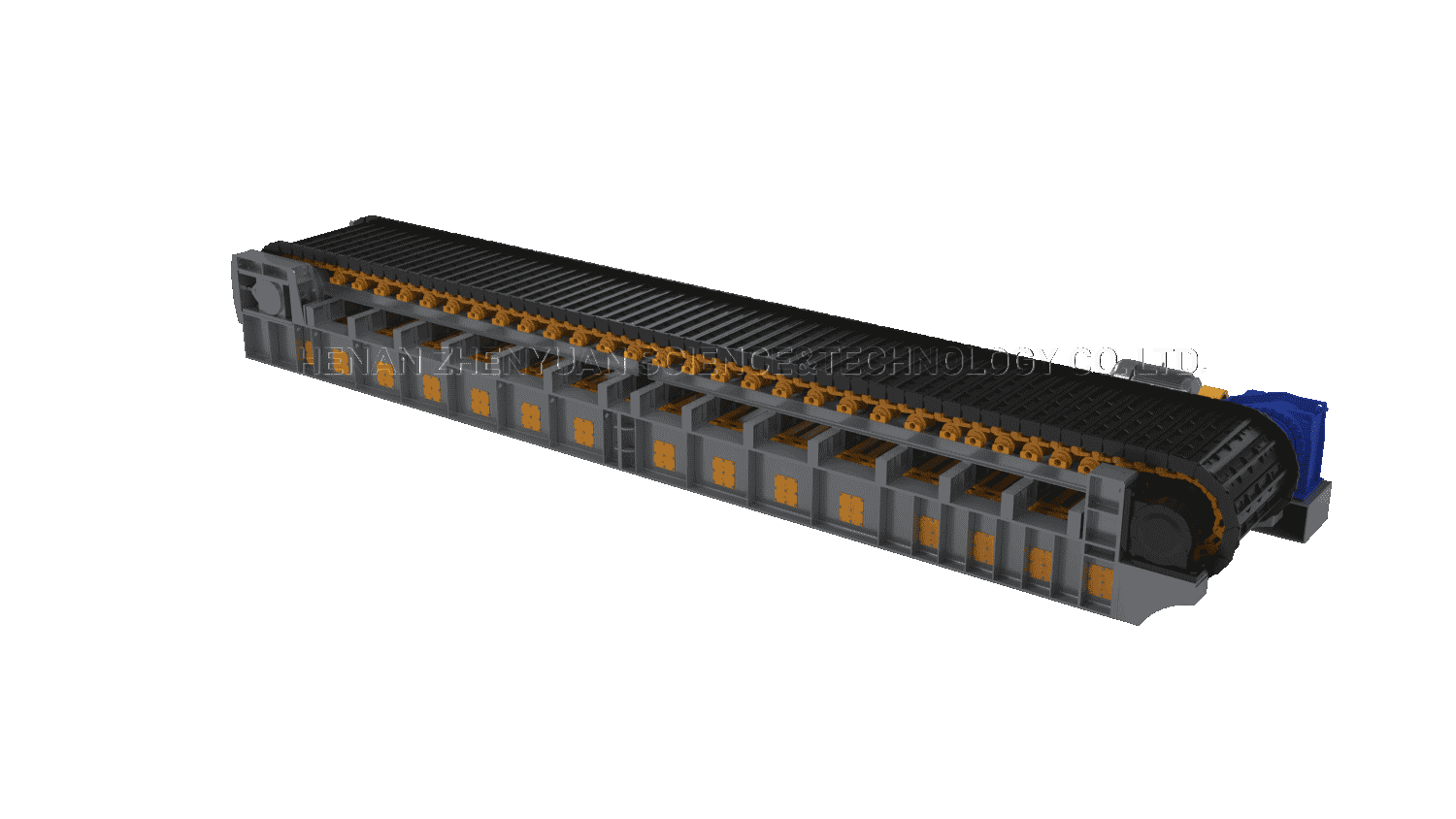

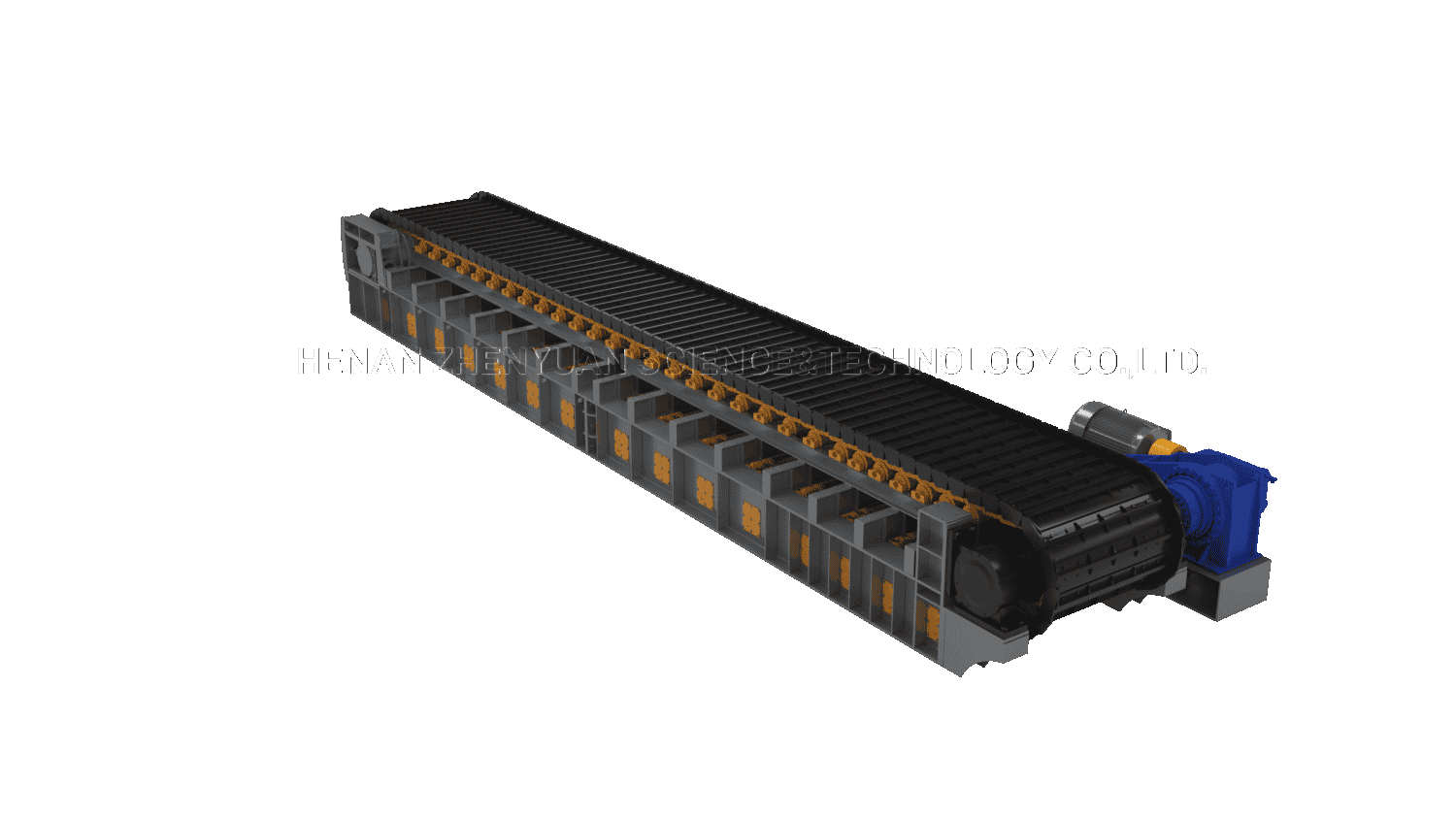

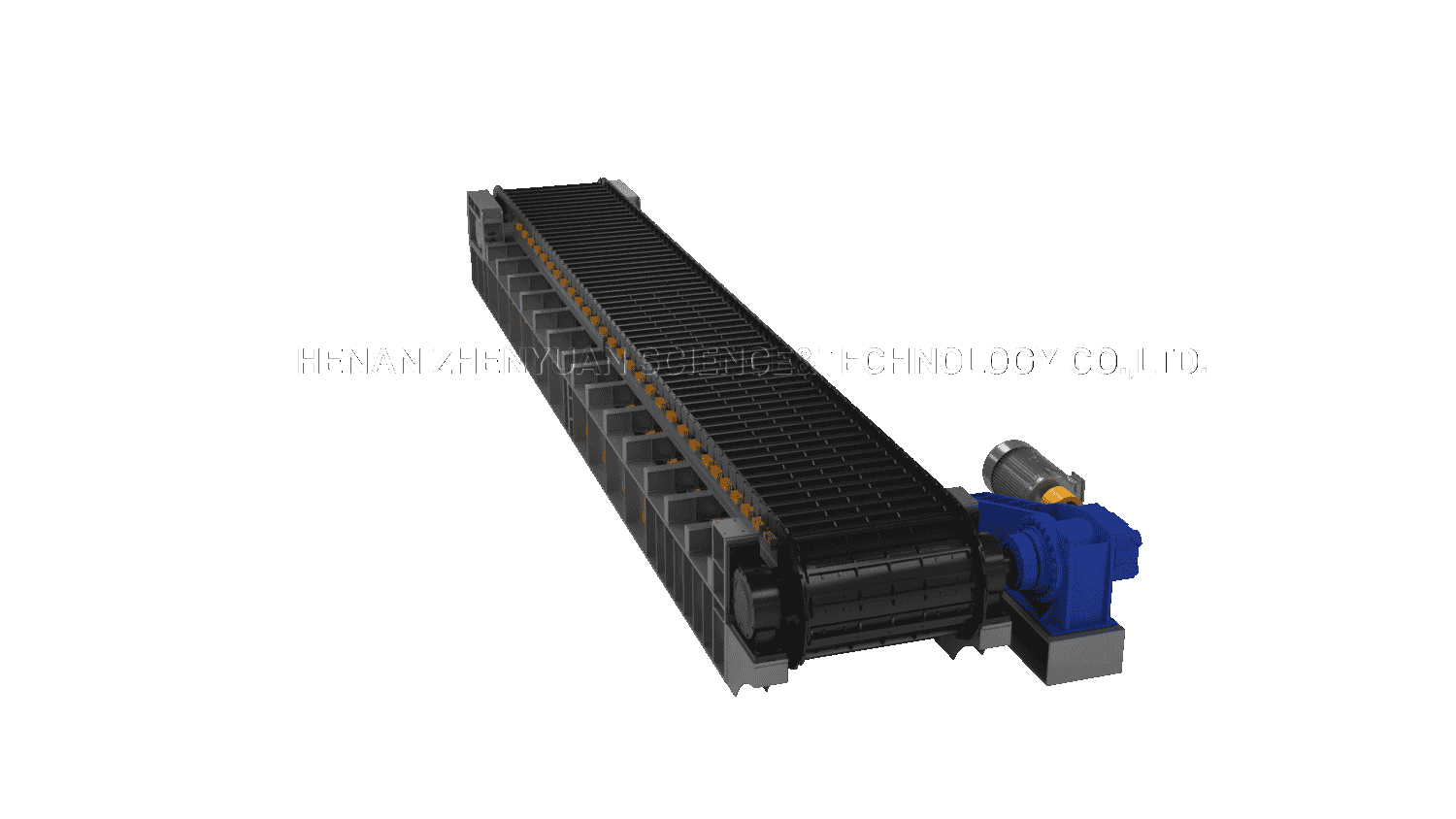

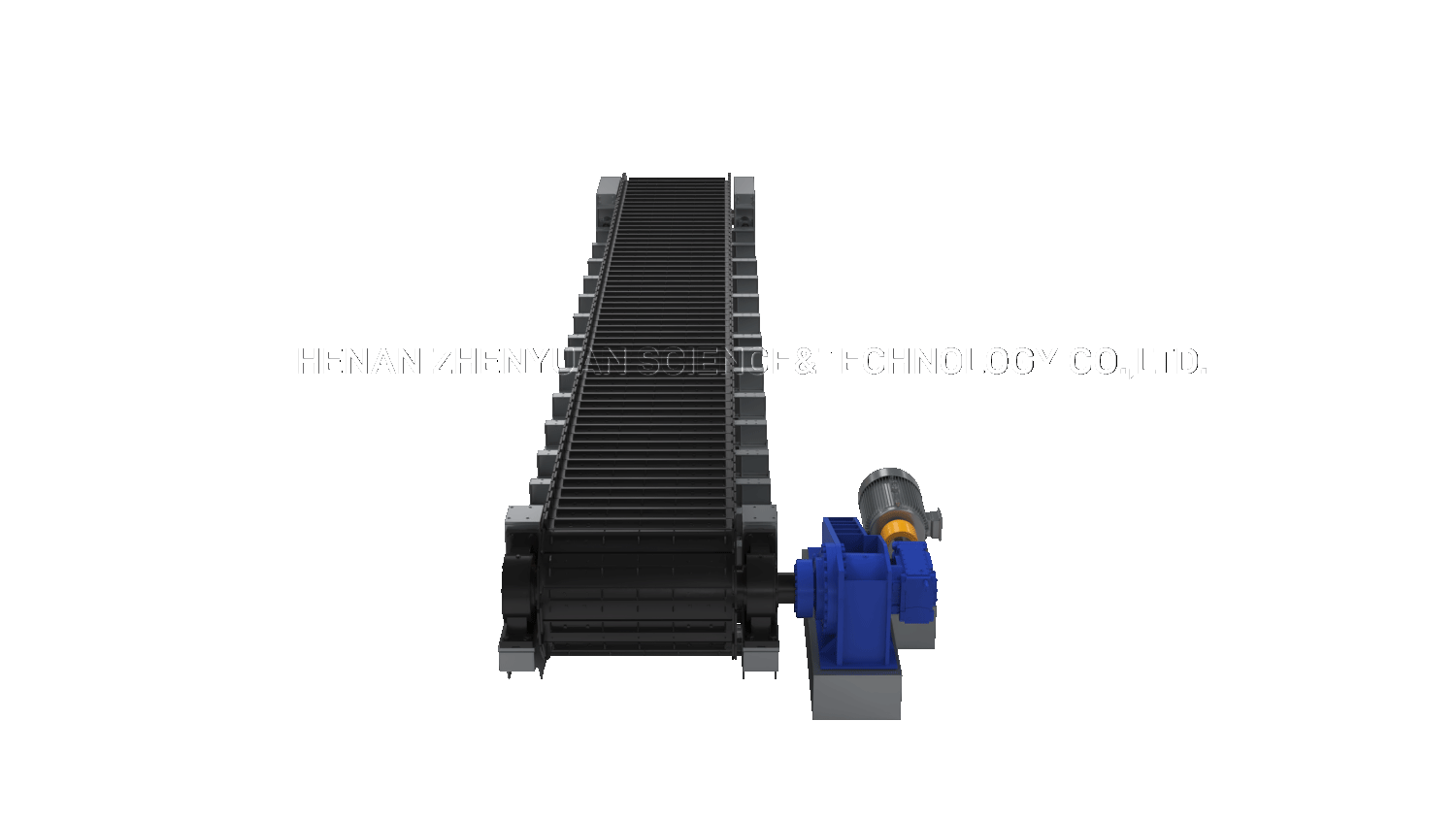

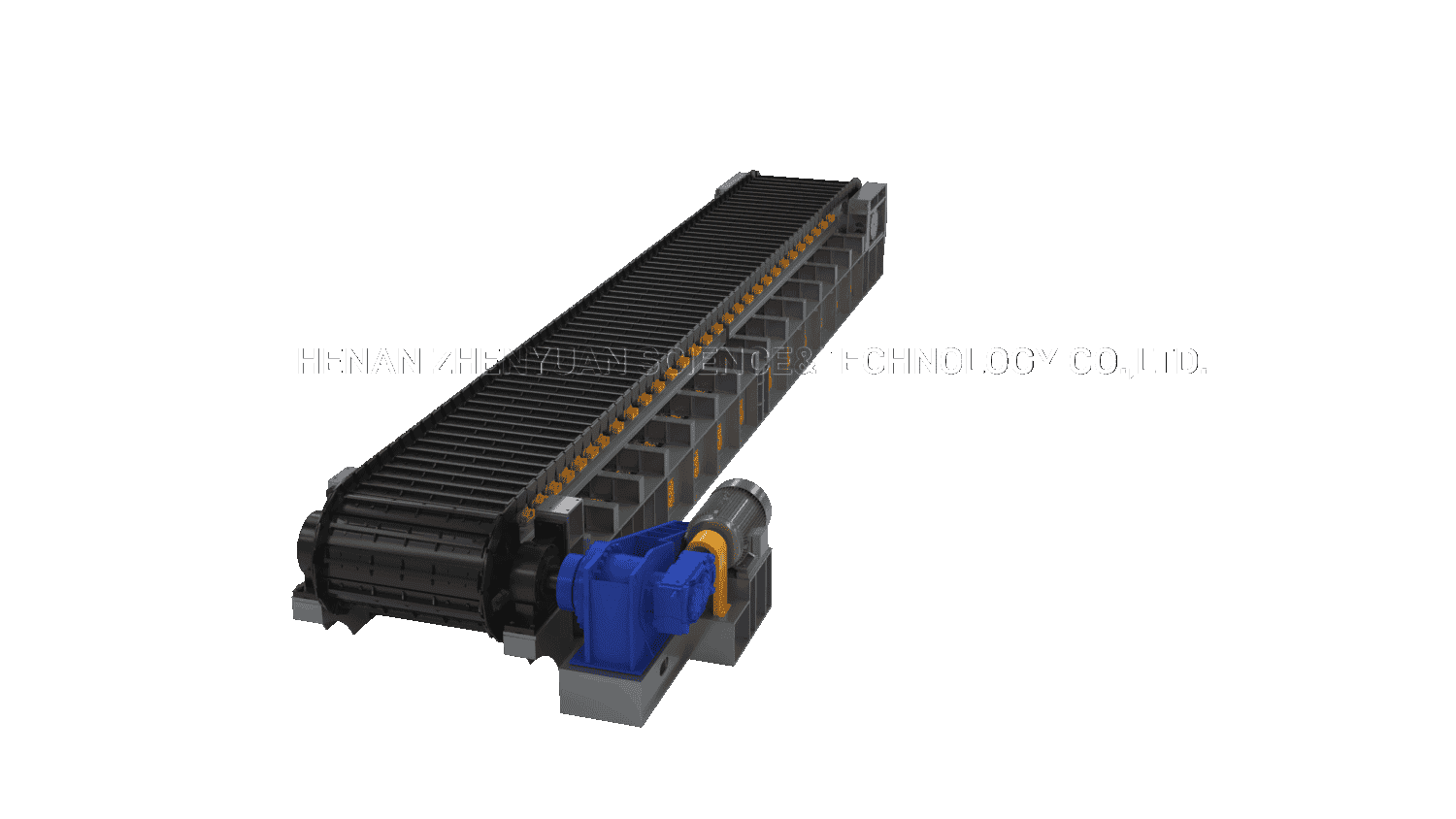

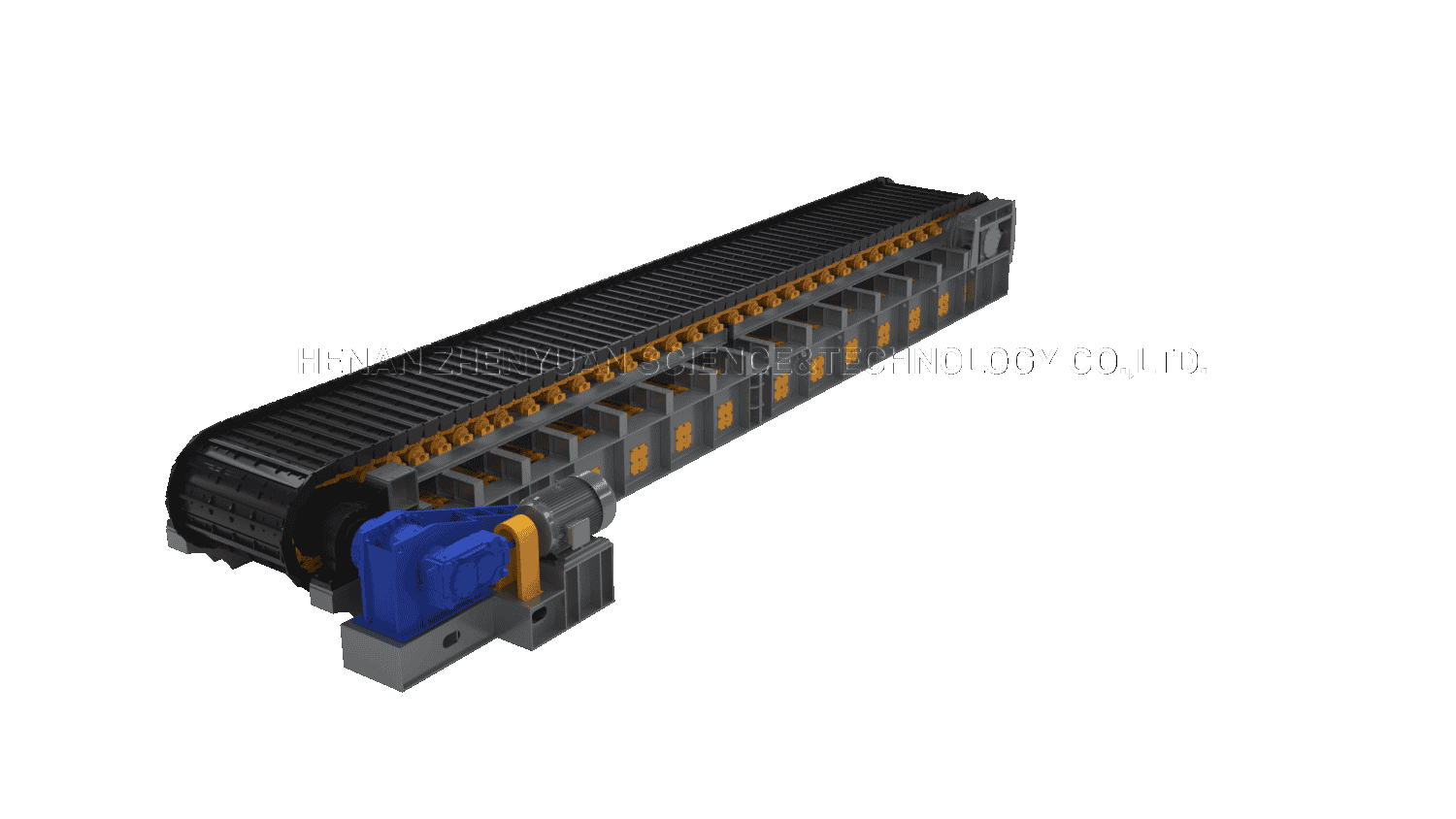

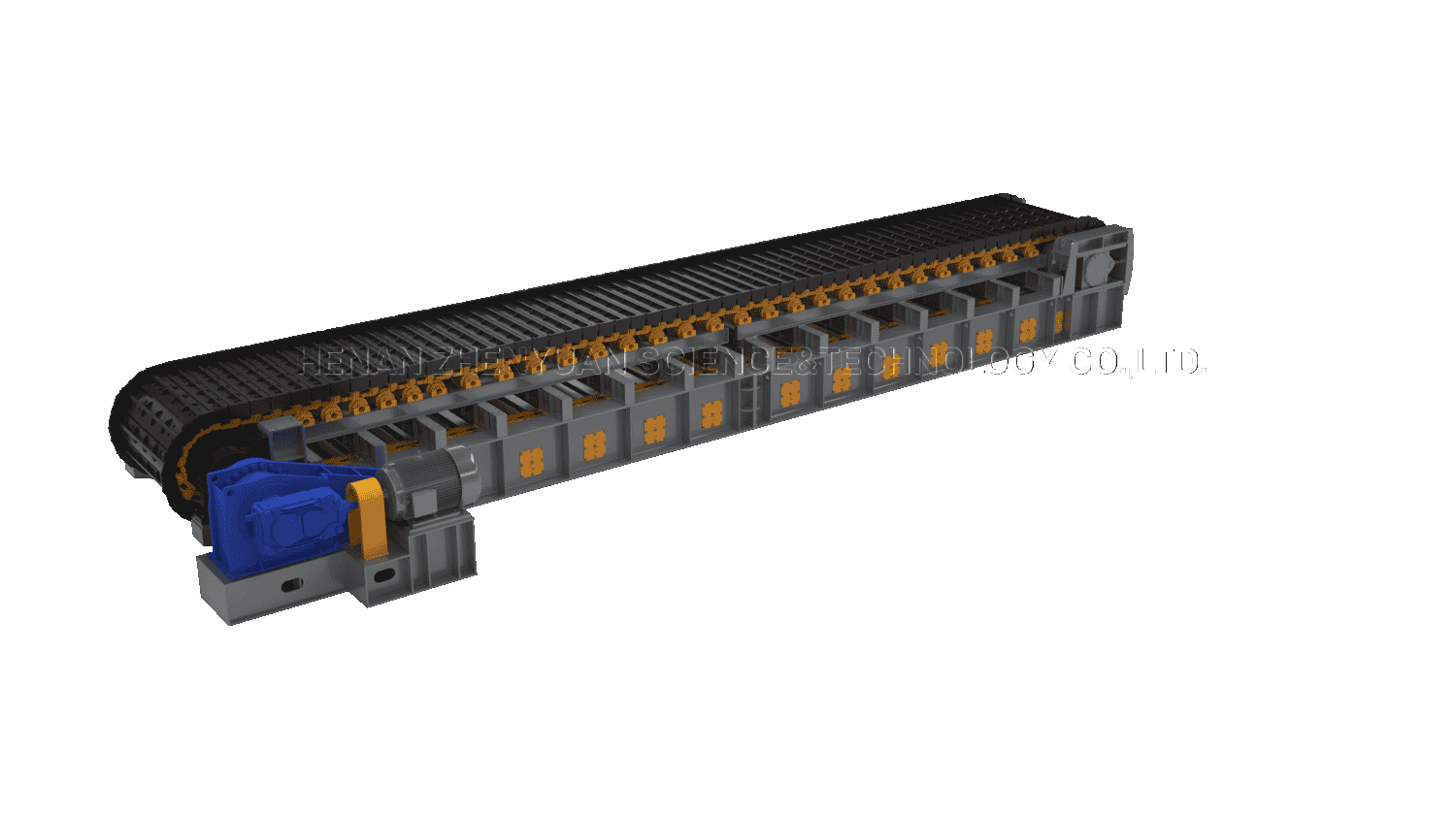

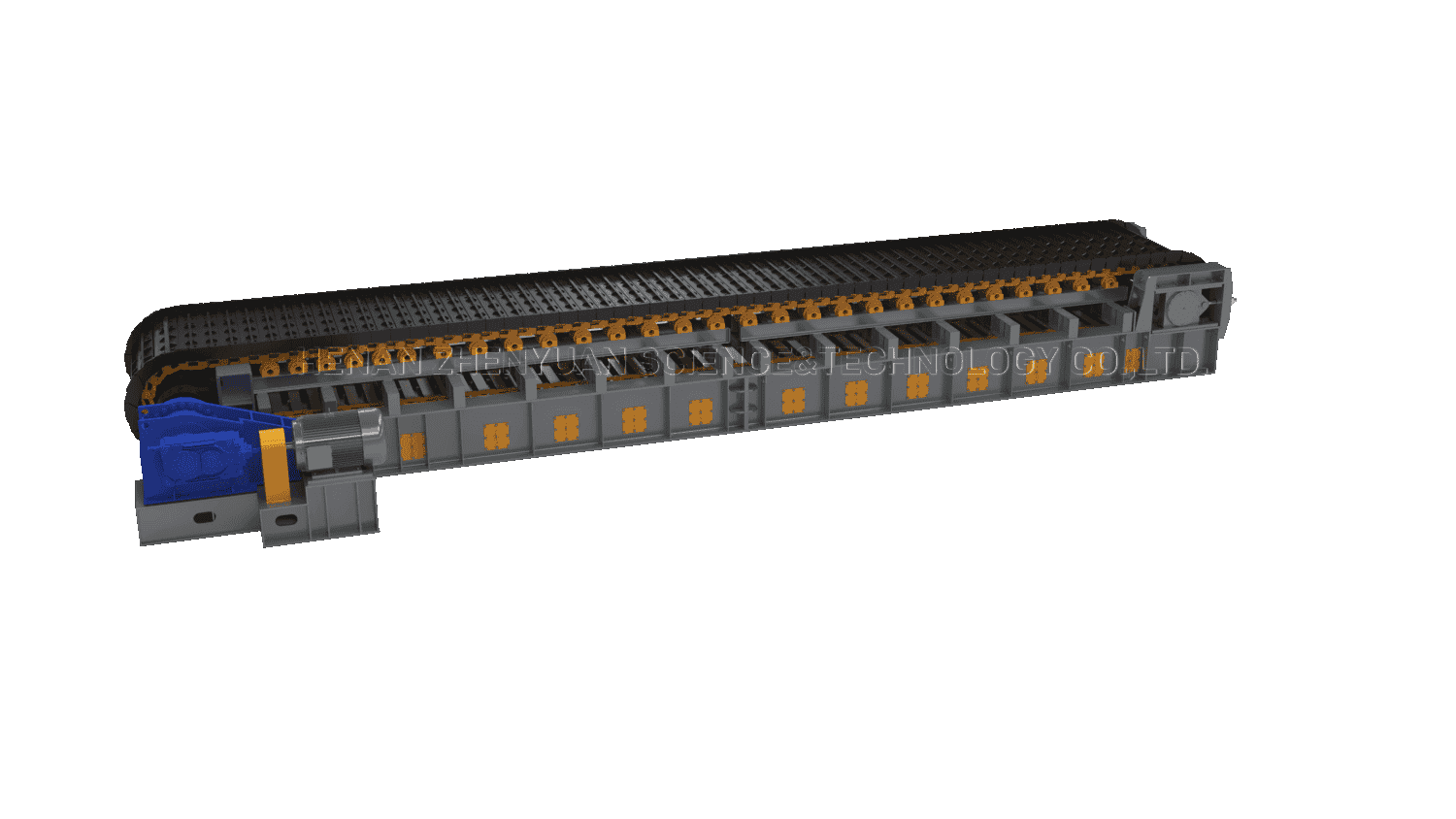

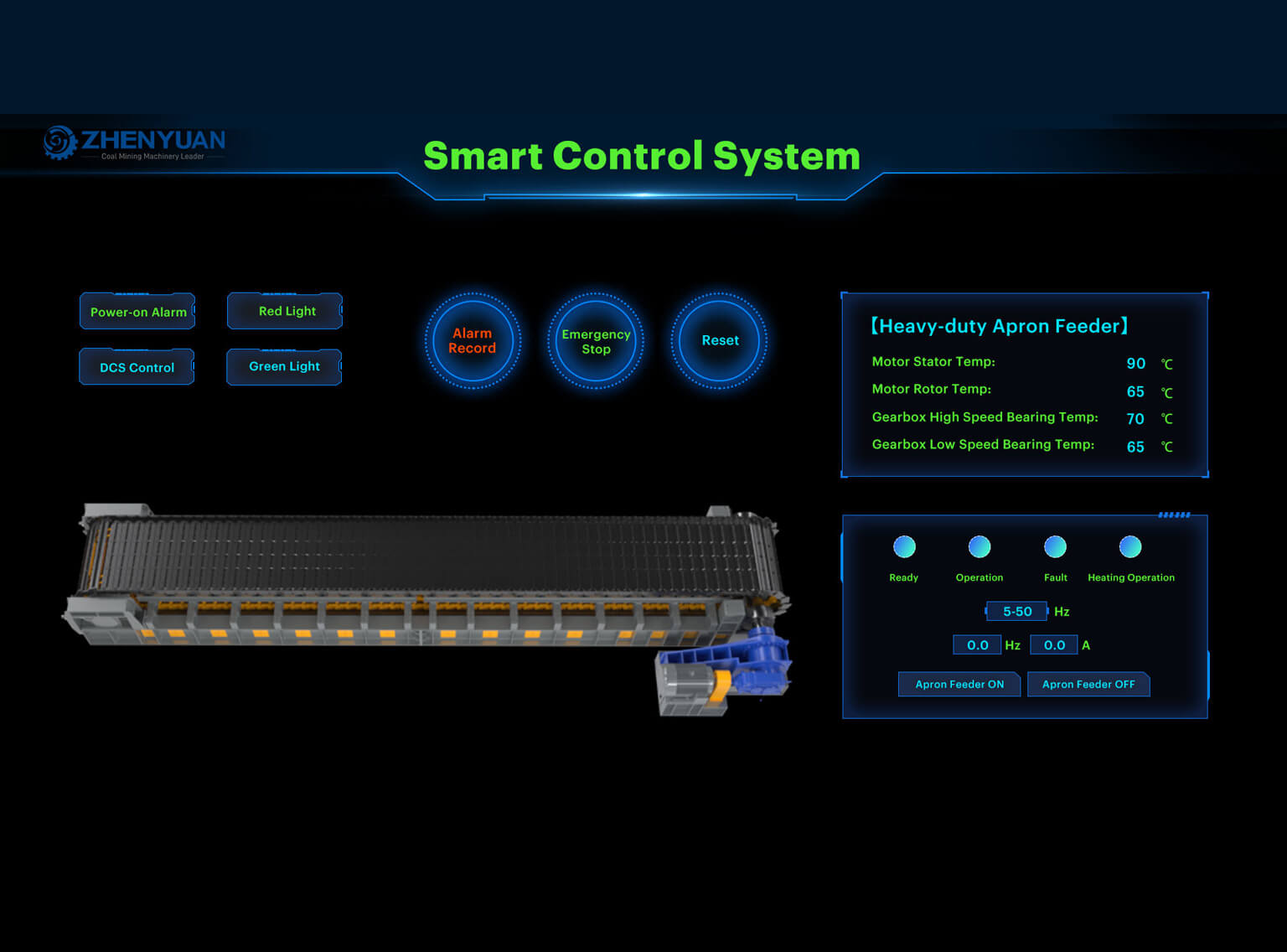

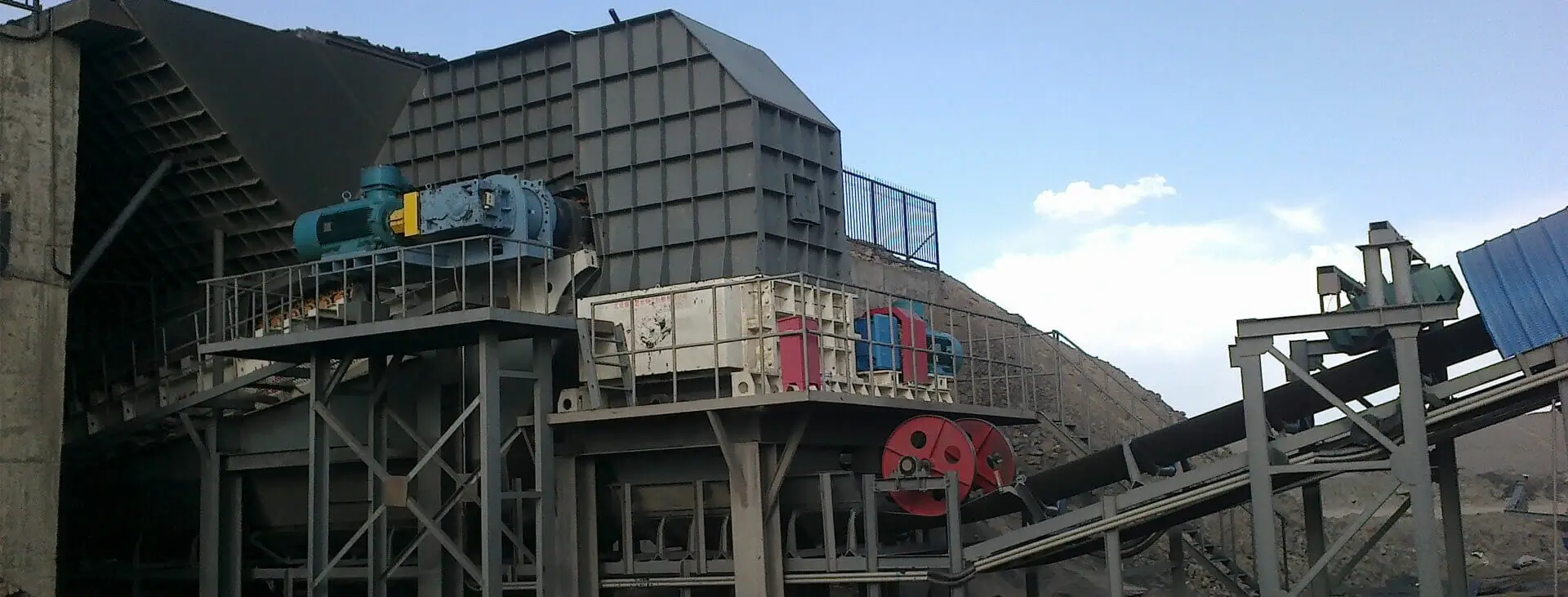

Heavy-duty Apron feeders are the preferred equipment for large-scale material handling processes. The apron feeder is primarily composed of a chain plate assembly, drive unit, load-bearing rollers, frame, and tensioning device.

Powered by an electric motor, the system adjusts rotational speed through gearbox to drive the rotation of a transmission sprocket. The sprocket drives a closed-loop traction chain, enabling continuous motion of the chain plates affixed to the chain.

Strong impact resistance, heavy-duty start-up, and stable feeding.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Pan Width |

Center Distance of Sprocket |

Feeding Speed |

Feeding Size |

Feeding Capacity |

|

(mm) |

(mm) |

(m/s) |

(mm) |

(t/h) |

|

|

ZBWJ1200-6 |

1200 |

6000 |

0.02-0.19 |

≤600 |

100-600 |

|

ZBWJ1400-8 |

1400 |

8000 |

0.02-0.19 |

≤800 |

100-800 |

|

ZBWJ1600-10 |

1600 |

10000 |

0.02-0.19 |

≤1000 |

200-1000 |

|

ZBWJ1800-12 |

1800 |

12000 |

0.02-0.25 |

≤1000 |

400-1500 |

|

ZBWJ2000-16 |

2000 |

16000 |

0.02-0.25 |

≤1200 |

600-2000 |

|

ZBWJ2400-18 |

2400 |

18000 |

0.02-0.25 |

≤1400 |

800-3000 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-30mm, 30-80mm

Capacity:1500-2000TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-30mm, 30-80mm

Capacity:1200-1500TPH

Processing Materials: Raw Coal&Coal Gangue

Input Size: 0-1200mm

Output Size: 0-50mm

Capacity: 1200-1500TPH

Processing Materials: Raw Coal

Input Size: 0-1500mm

Output Size: 0-300mm

Capacity: 2500-3000TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-30mm, 30-80mm

Capacity: 2500-3000TPH

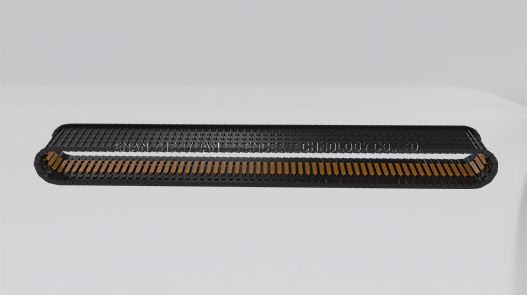

Apron Pan

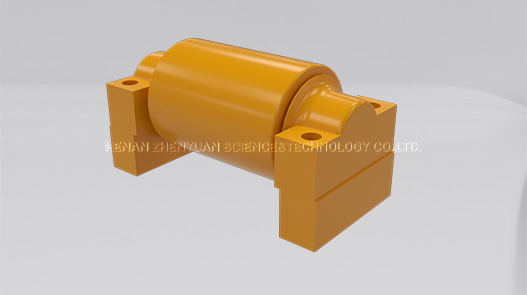

Return Roller

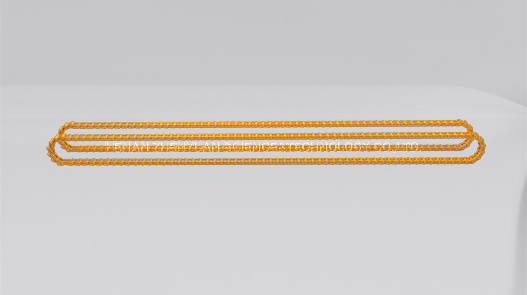

Chains

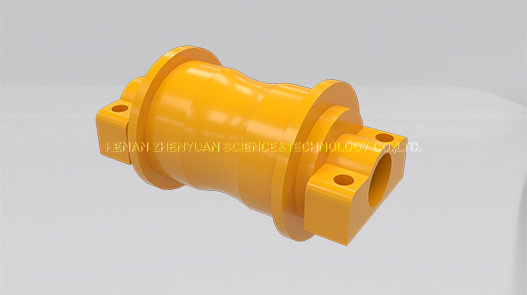

Support Roller