The High production capacity with a large crushing ratio, capable of breaking large blasts to below 70mm in one go, with a single machine's maximum output reaching up to 5000 tons per hour.

Low energy consumption, energy-saving and power-efficient, saving more than 50% energy compared to similar products, with a single motor operation that consumes only 0.5 kWh of electricity per ton of crushed stone.

Fully screened structure, excellent finished product grain shape, more polygons, fewer needle-like pieces, and stone powder content as low as 13%, making it the best choice for concrete aggregate crushing.

Simple operation, high level of intelligence, easy maintenance, and improved labor intensity for workers.

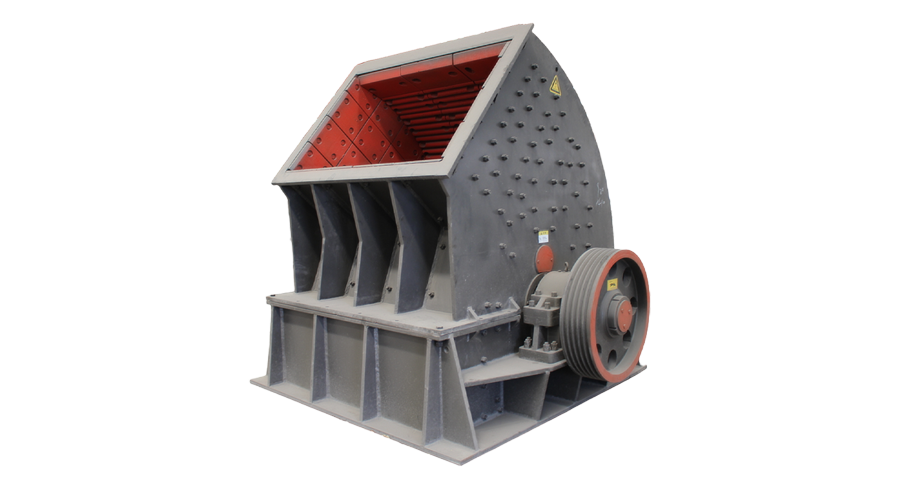

The rotor adopts large belt pulley structure, which increases the inertia and stability of the rotor. The internal full screening structure reduces the number of hammer heads, reduces the wear of wear-resistant parts, and the new hammer crusher reduces the number of hammer heads to one-third of the old hammer (from more than 70 to 12-18), reduces the labor intensity of workers, reduces the production cost, increases the blanking area of stone, and improves the passing amount of stone.

Wear resistant sheath is installed around the new hammer rotor disc, and the stone will not wear directly with the rotor disc, which increases the service life of the rotor.

The upper part of the shell of the new hammer crusher is installed with inverted nail type counterattack plate, which replaces the traditional counterattack lining plate, improves the crushing rate of the stone forging link and increases the output of the equipment.

Submit your details and Talk with one of our technical engineer about your project.

Send Email| Primary Mineral Sizer | ||||||

|

Model |

Max. Input Size (mm) |

Rotor Dia. (mm) |

Rotor Length (mm) |

Capacity (tph) |

Rotating Speed (rpm) |

Power (kw) |

|

PCZ1616 |

≤700 |

1600 |

1600 |

200-300 |

420 |

250 |

|

PCZ1620 |

≤700 |

1600 |

2000 |

300-400 |

420 |

315 |

|

PCZ1624 |

≤700 |

1600 |

2400 |

350-450 |

420 |

355 |

|

PCZ1820 |

≤700 |

1800 |

2000 |

450-550 |

350 |

400 |

|

PCZ1824 |

≤700 |

1800 |

2400 |

550-650 |

350 |

500 |

|

PCZ1826 |

≤800 |

1800 |

2600 |

650-800 |

350 |

560 |

|

PCZ2224 |

≤1000 |

2200 |

2400 |

800-1000 |

350 |

800 |

|

PCZ2226 |

≤1000 |

2200 |

2600 |

1000-1300 |

350 |

1000 |

|

PCZ2426 |

≤1000 |

2400 |

2600 |

1500-1800 |

280 |

1120 |

|

PCZ2626 |

≤1000 |

2600 |

2600 |

2000-2500 |

280 |

1250 |

|

PCZ2630 |

≤1000 |

2600 |

3000 |

3000-3500 |

280 |

1600 |

|

PCZ3030 |

≤1000 |

3000 |

3000 |

4000-4500 |

280 |

1000×2 |

|

PCZ3032 |

≤1100 |

3000 |

3200 |

5000-5500 |

280 |

1250×2 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.