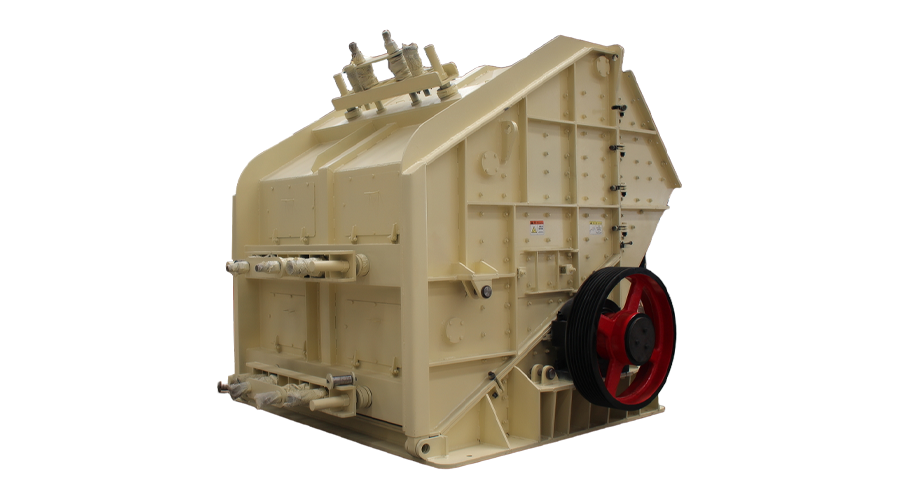

The entire machine is designed using ANSYS finite element computer-aided design and manufactured with high-strength, premium-quality steel.

The high-precision, heavy-duty rotor with a large moment of inertia is designed in conjunction with the overall manufacturing process of CNC machine tools, significantly increasing the rotor's operating speed and the equipment's crushing capacity.

The multifunctional fully hydraulic operating system allows for easy adjustment of discharge particle size and machine maintenance, reducing operational intensity and improving the startup rate.

The optimized involute crushing chamber design ensures high crushing efficiency, excellent particle shape, and extremely low flake content.

The crescent-shaped hammer plate changes the impact angle, increasing the effective impact area, resulting in higher crushing efficiency and greater durability.

The hammer plate is secured with a wedge block axial positioning device, ensuring that the faster the rotor speed, the more securely the hammer plate is fixed, providing safe and reliable operation and easier replacement.

A variety of models, including two-chamber and three-chamber options, are available to meet the crushing requirements for coarse, medium, and fine crushing operations.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Feed Inlet Size (mm) |

Max. Input Size (mm) |

Rotor Dia. (mm) |

Rotor Length (mm) |

Capacity (tph) |

Rotating Speed (rpm) |

Power (kw) |

|

NP1317 |

1730×960 |

600 |

1300 |

1750 |

300-500 |

600 |

200-315 |

|

NP1323 |

2310×960 |

600 |

1300 |

2320 |

400-600 |

600 |

250-355 |

|

NP1520 |

2050×960 |

700 |

1500 |

2100 |

500-800 |

550 |

2×200 |

|

NP1523 |

2350×960 |

700 |

1500 |

2300 |

600-900 |

550 |

2×250 |

|

NP1620 |

2050×1600 |

800 |

1600 |

2100 |

600-900 |

450 |

2×250 |

|

NP1624 |

2450×1600 |

800 |

1600 |

2500 |

700-1000 |

450 |

2×315 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Raw Coal&Coal Gangue

Input Size: 0-1200mm

Output Size: 0-50mm

Capacity: 1200-1500TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-300mm

Capacity:1000-1200TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-30mm, 30-80mm, 80-140mm, 140-300mm

Capacity:1500TPH