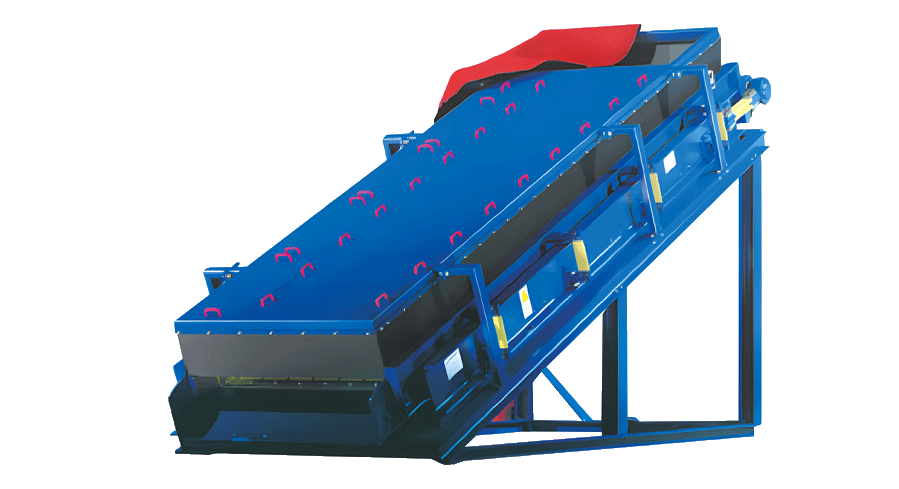

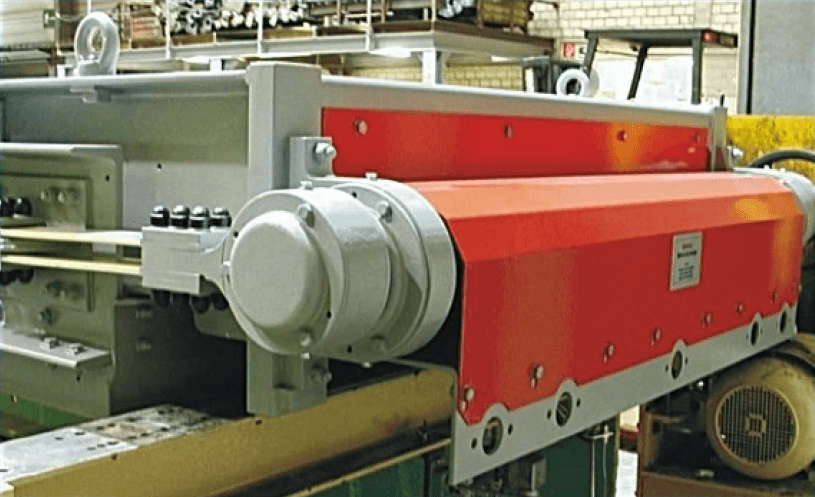

Mechanical flip-flow screen, also known as crank-connecting rod flip-flow screen. The screen body mainly consists of inner and outer screen frames. The inner screen frame is mounted on the machine frame through rubber damping springs, while the outer screen frame is suspended from the inner frame via glass fiber-reinforced leaf springs. Under external drive, the two frames perform relative parallel movements.

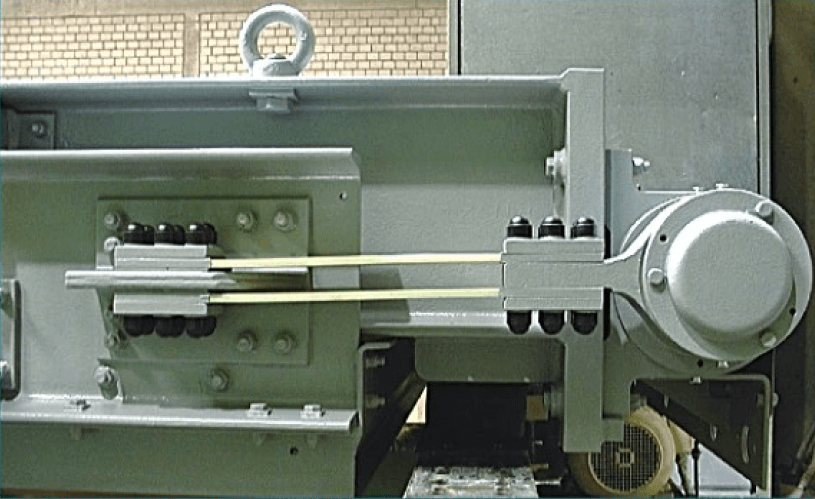

The motion mechanism is powered by a motor-driven eccentric shaft. Through push rod springs, the eccentric shaft continuously pushes and pulls the outer frame, generating counter-directional linear motion between the inner and outer frames. Consequently, the crossbeams installed on the frames drive the flexible screen panels to perform alternating slackening and tensioning movements.

Advanced Screening Technology: Thanks to a thorough understanding and application of material screening theory, from the perspective of screening mechanism, when materials are thrown up on the relaxation surface, they are subjected to forces from multiple directions, promoting the separation of coarse and fine particles, thereby improving screening efficiency.

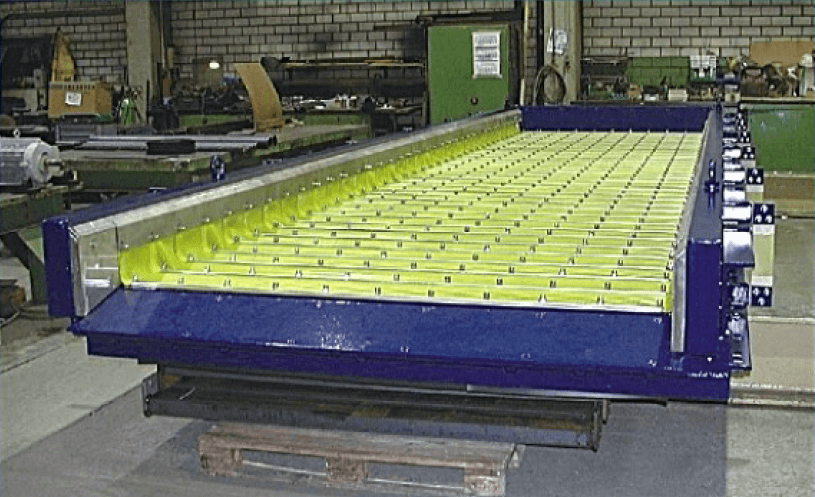

The floating beam of the screen machine is designed with square tubes, making the structure more robust and stable.

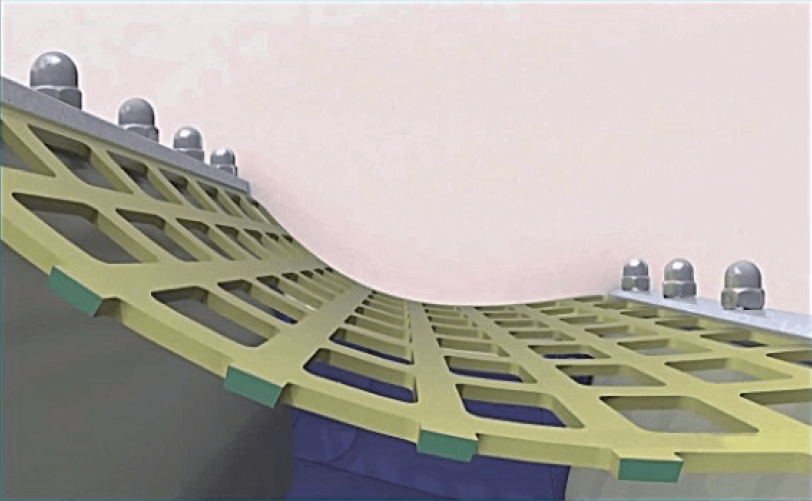

The screen machine features a large curvature radius design on the side horns, preventing oversize material from leaking to the undersize side, while also reducing the bending strength of the screen plates and extending their service life.

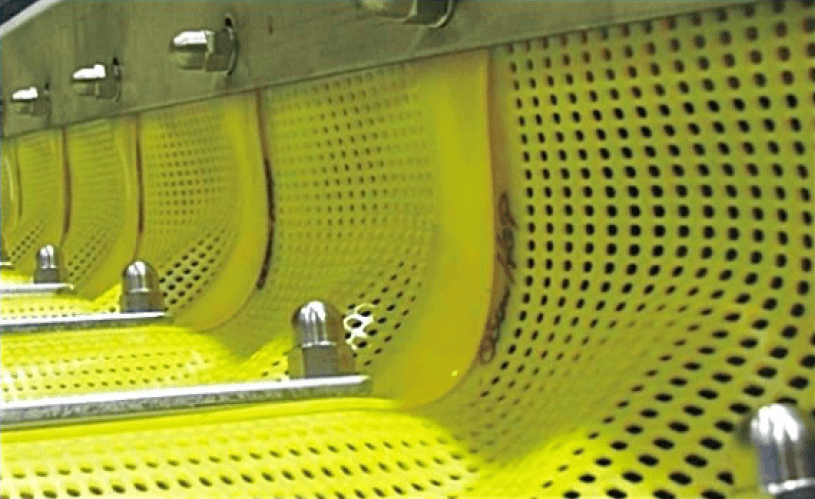

The screen plates are fixed using a "press-in and pry-out" method, requiring no bolts for fixation. The screen plates are simple to disassemble and replace quickly, preventing wear and detachment of bolts during long-term operation of the screen machine.

The high acceleration allows the screening materials to be completely loosened and quickly separated, achieving a higher rate of undersize material passage. Under high acceleration, it effectively prevents particles close to the screen aperture size from blocking the screen holes.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Screen Plate |

Max. Input Size |

Capacity |

Electrical Motor |

|||

|

Layer(s) |

Area(m2) |

Mesh Size(mm) |

(mm) |

(t/h) |

Power(kw) |

Qty(pcs) |

|

|

MFF2.0-6.30 |

1 |

12.6 |

3-13 |

80 |

150-400 |

22 |

1 |

|

2MFF2.0-6.30 |

2 |

12.6×2 |

Upper:14-30 Lower: 3-13 |

80 |

350-650 |

37 |

1 |

|

MFF2.2-7.56 |

1 |

16.6 |

3-13 |

80 |

250-500 |

37 |

1 |

|

2MFF2.2-7.56 |

2 |

16.6×2 |

Upper:14-30 Lower: 3-13 |

80 |

450-750 |

45 |

1 |

|

MFF2.2-8.82 |

1 |

19.4 |

3-13 |

80 |

250-600 |

37 |

1 |

|

2MFF2.2-8.82 |

2 |

19.4×2 |

Upper:14-30 Lower: 3-13 |

80 |

500-900 |

45 |

1 |

|

MFF2.6-8.82 |

1 |

22.9 |

3-13 |

100 |

350-750 |

37 |

1 |

|

2MFF2.6-8.82 |

2 |

22.9×2 |

Upper:14-30 Lower: 3-13 |

100 |

650-1100 |

45 |

1 |

|

MFF3.0-8.82 |

1 |

26.5 |

3-13 |

100 |

400-950 |

45 |

1 |

|

2MFF3.0-8.82 |

2 |

26.5×2 |

Upper:14-30 Lower: 3-13 |

100 |

800-1400 |

75 |

1 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Coal

Input Size: 0-50mm

Screen Mesh Size: 6mm

Capacity: 700-750TPH

Processing Materials: Coal

Input Size: 0-30mm

Screen Mesh Size: 8mm

Capacity: 500-550TPH