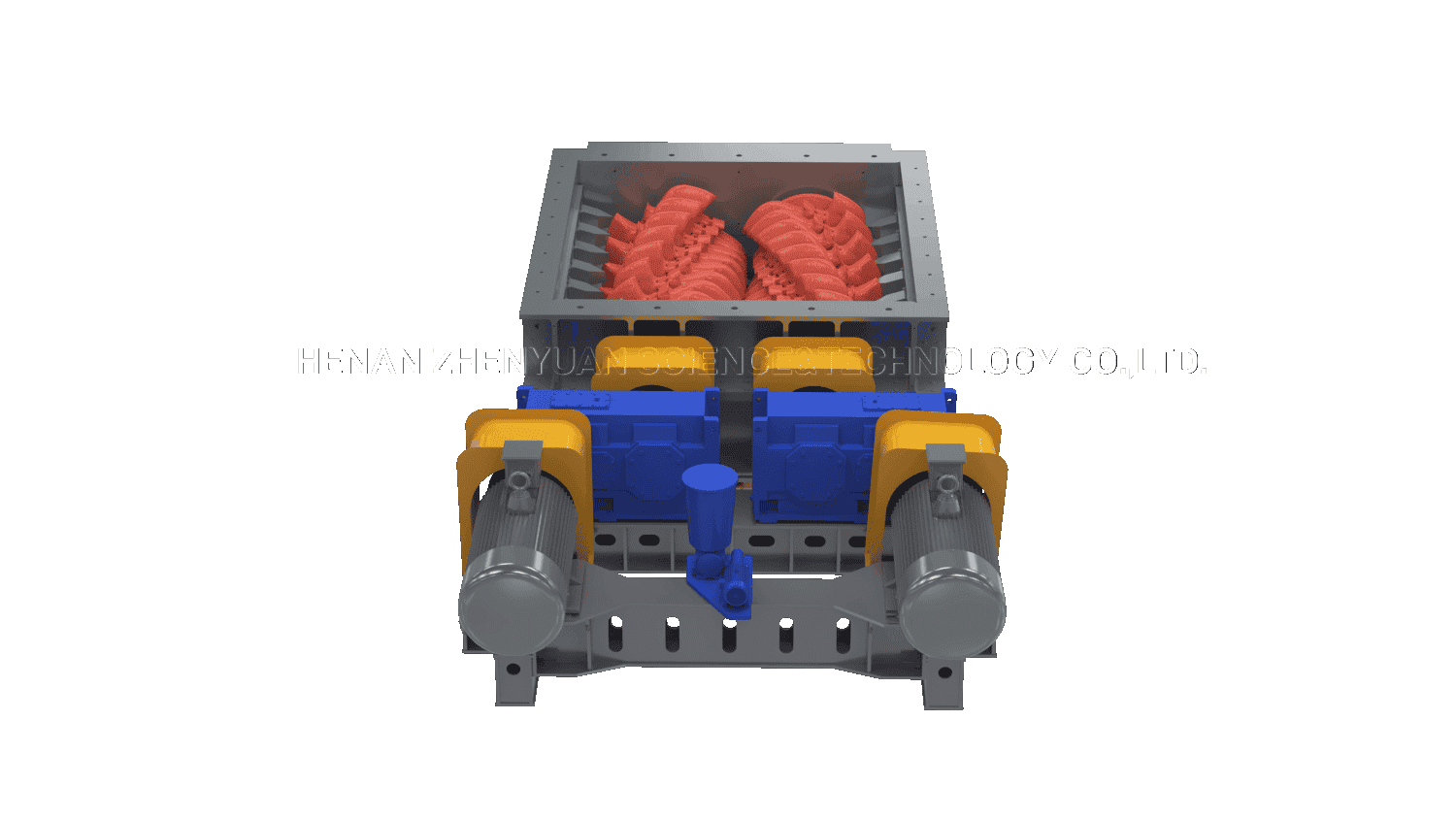

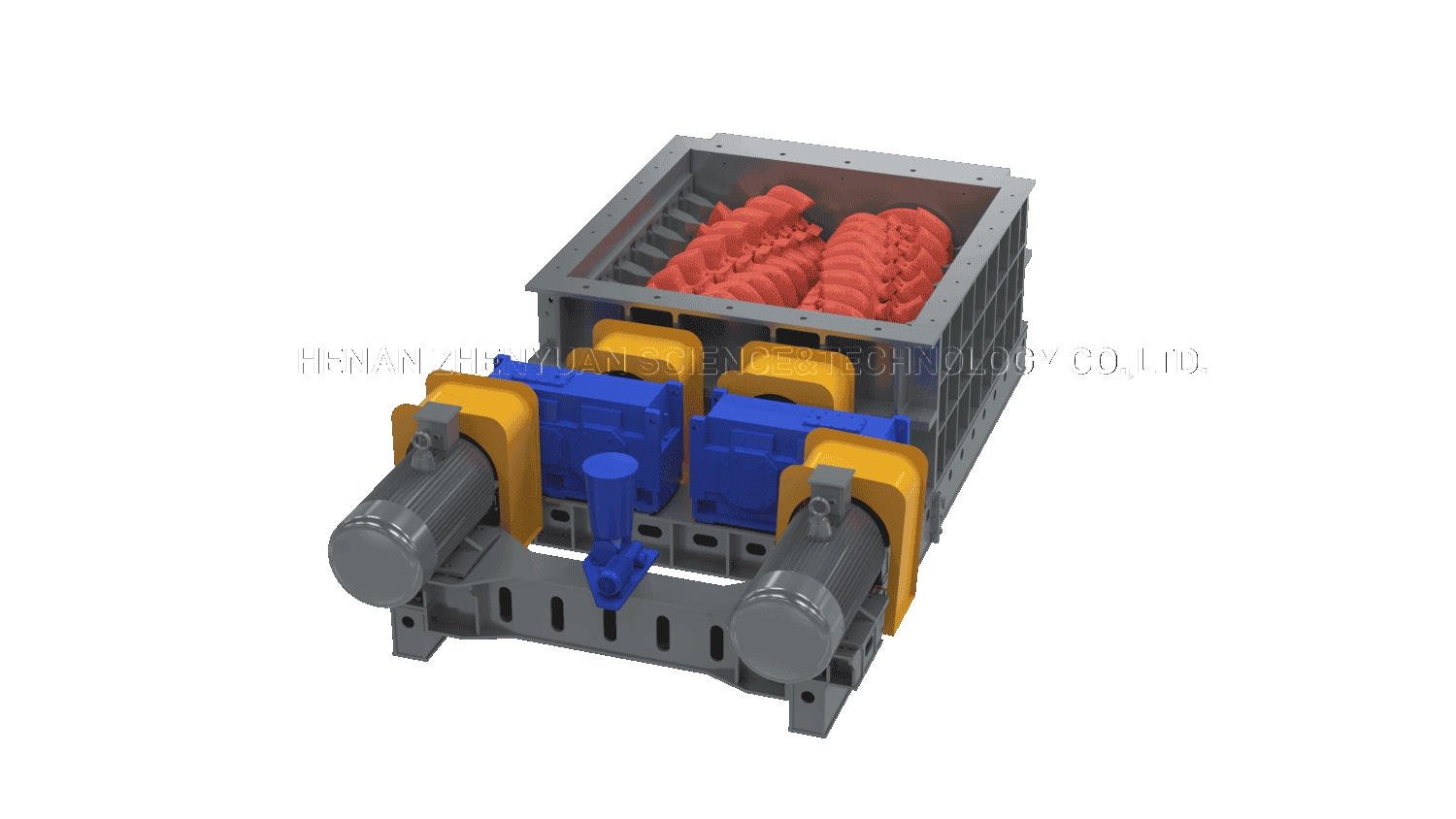

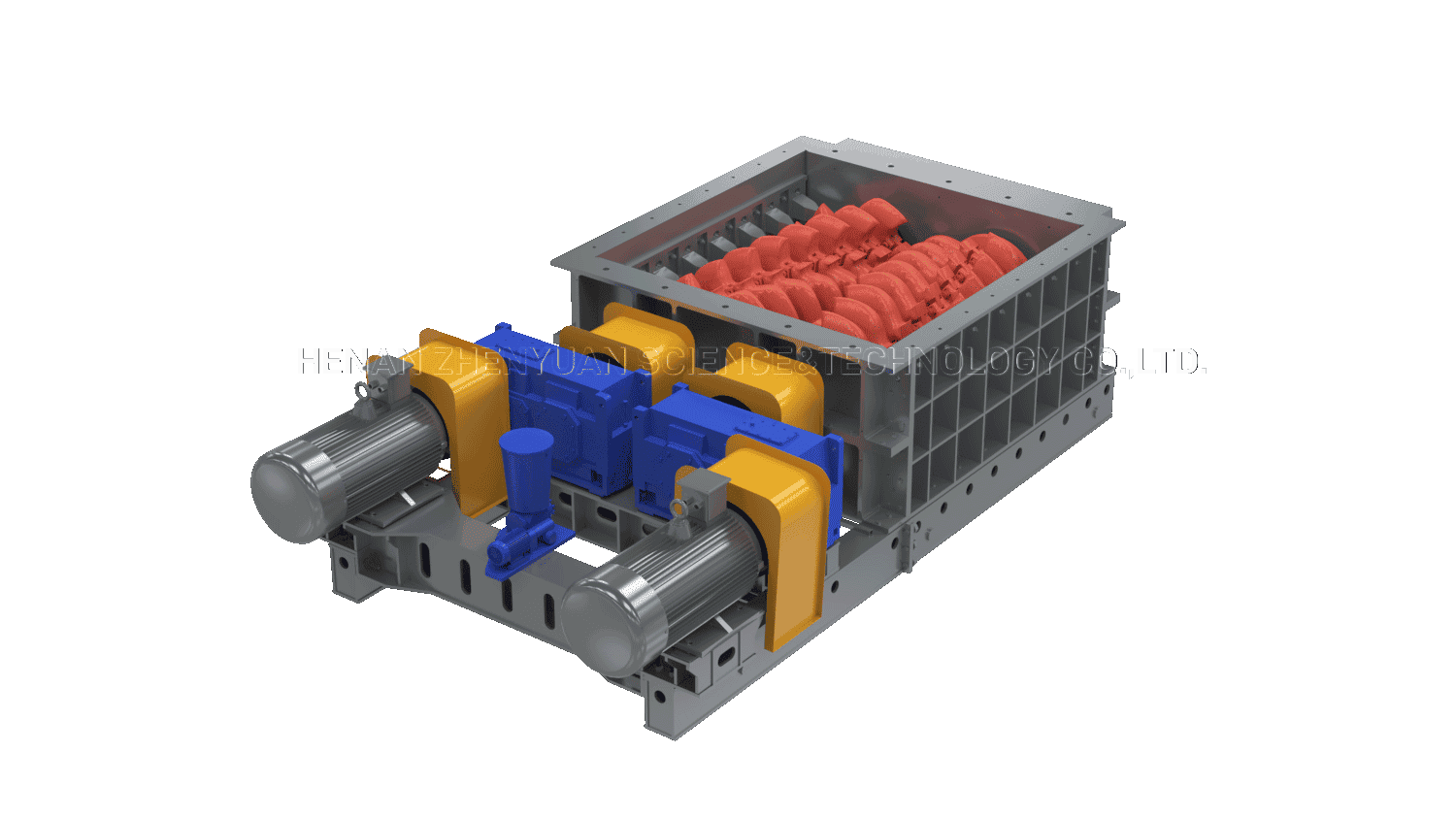

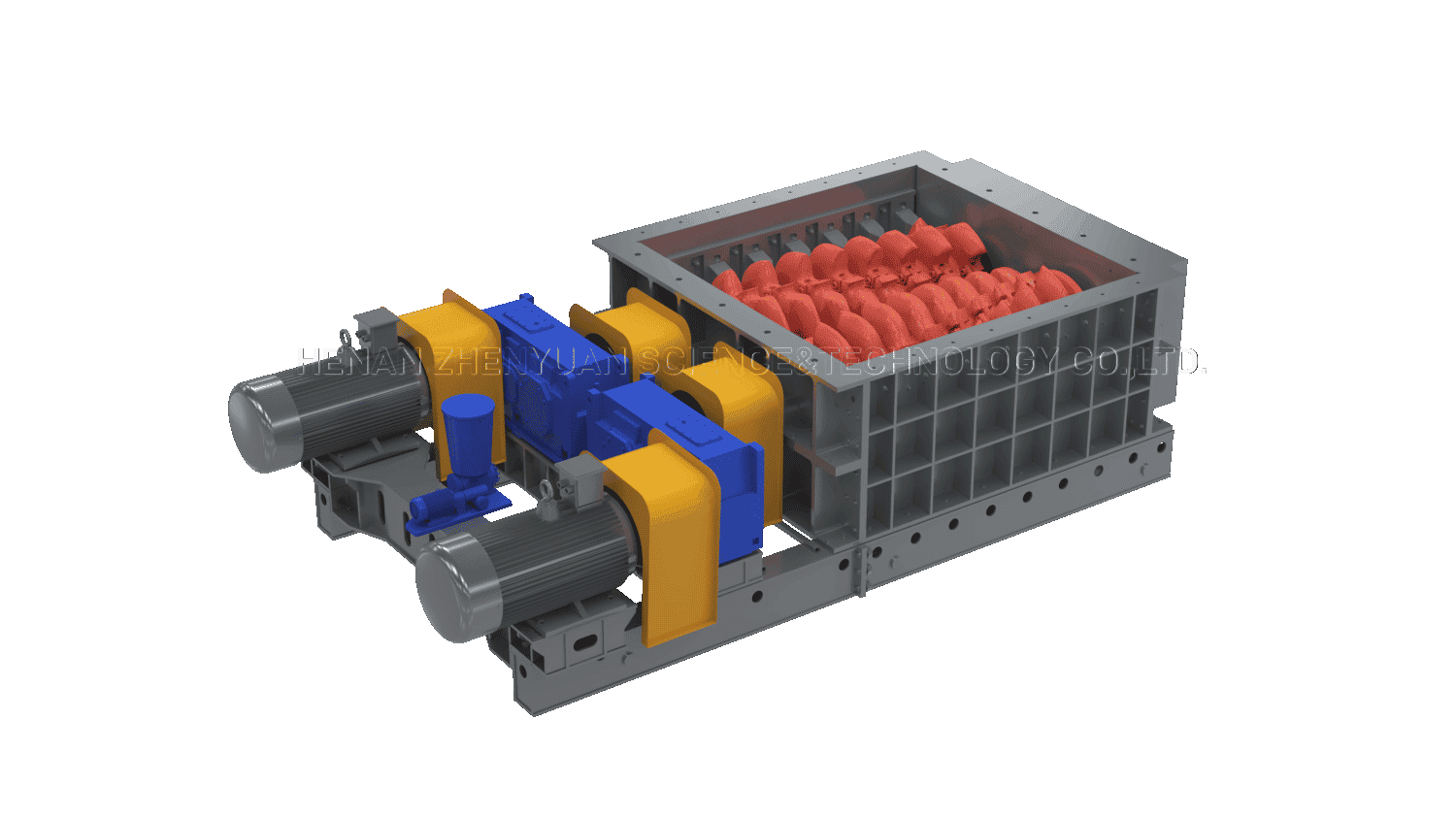

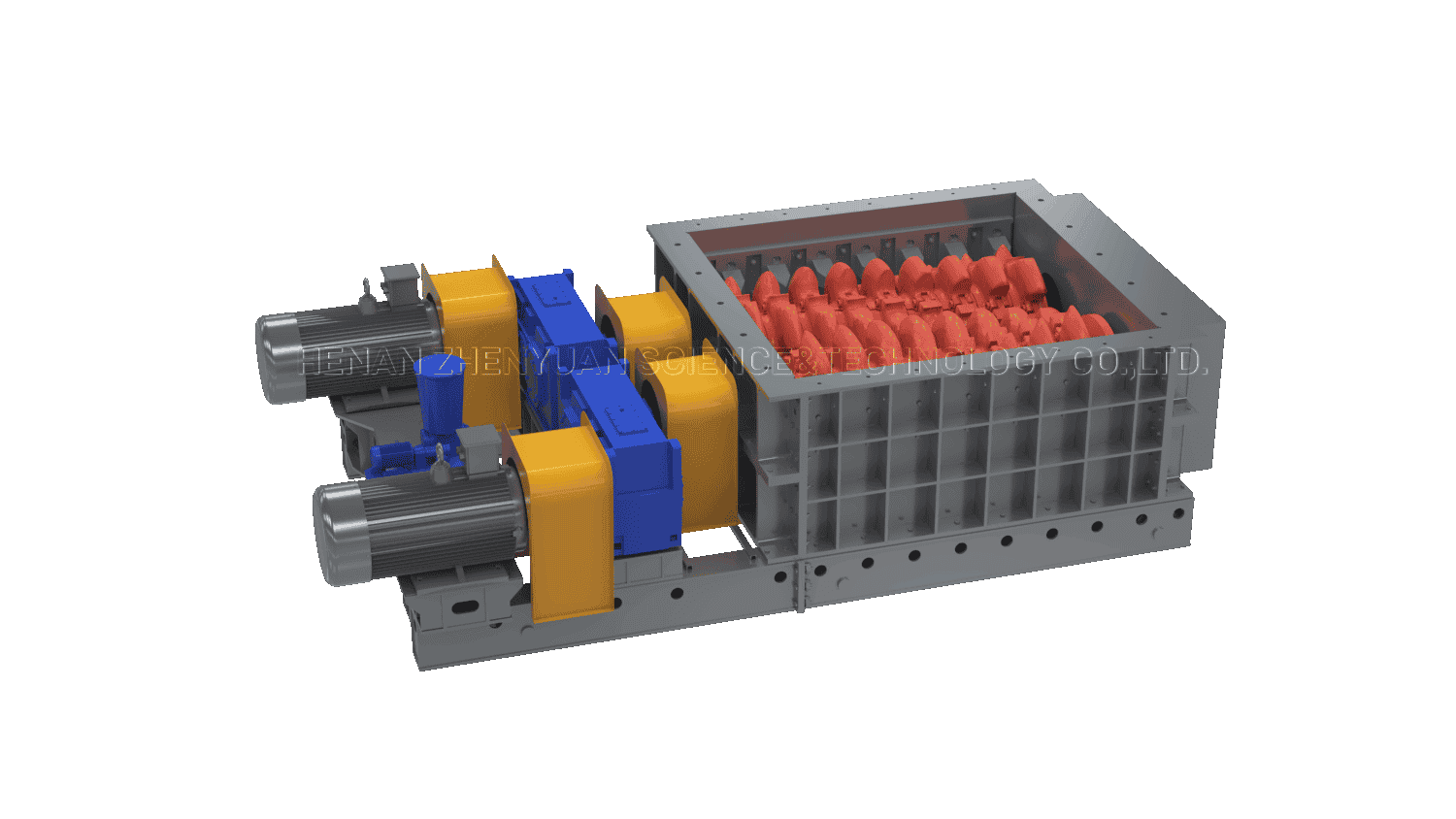

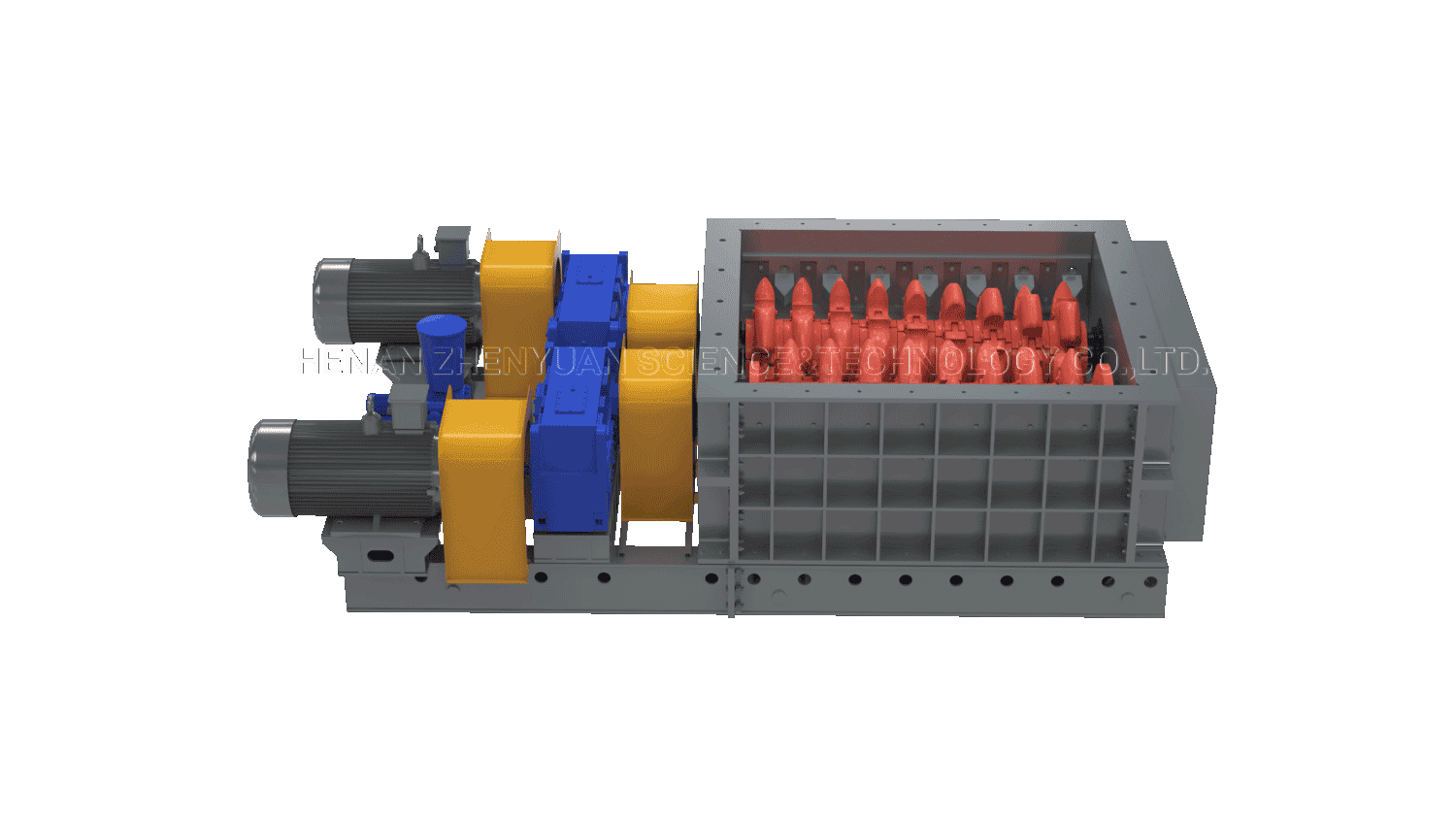

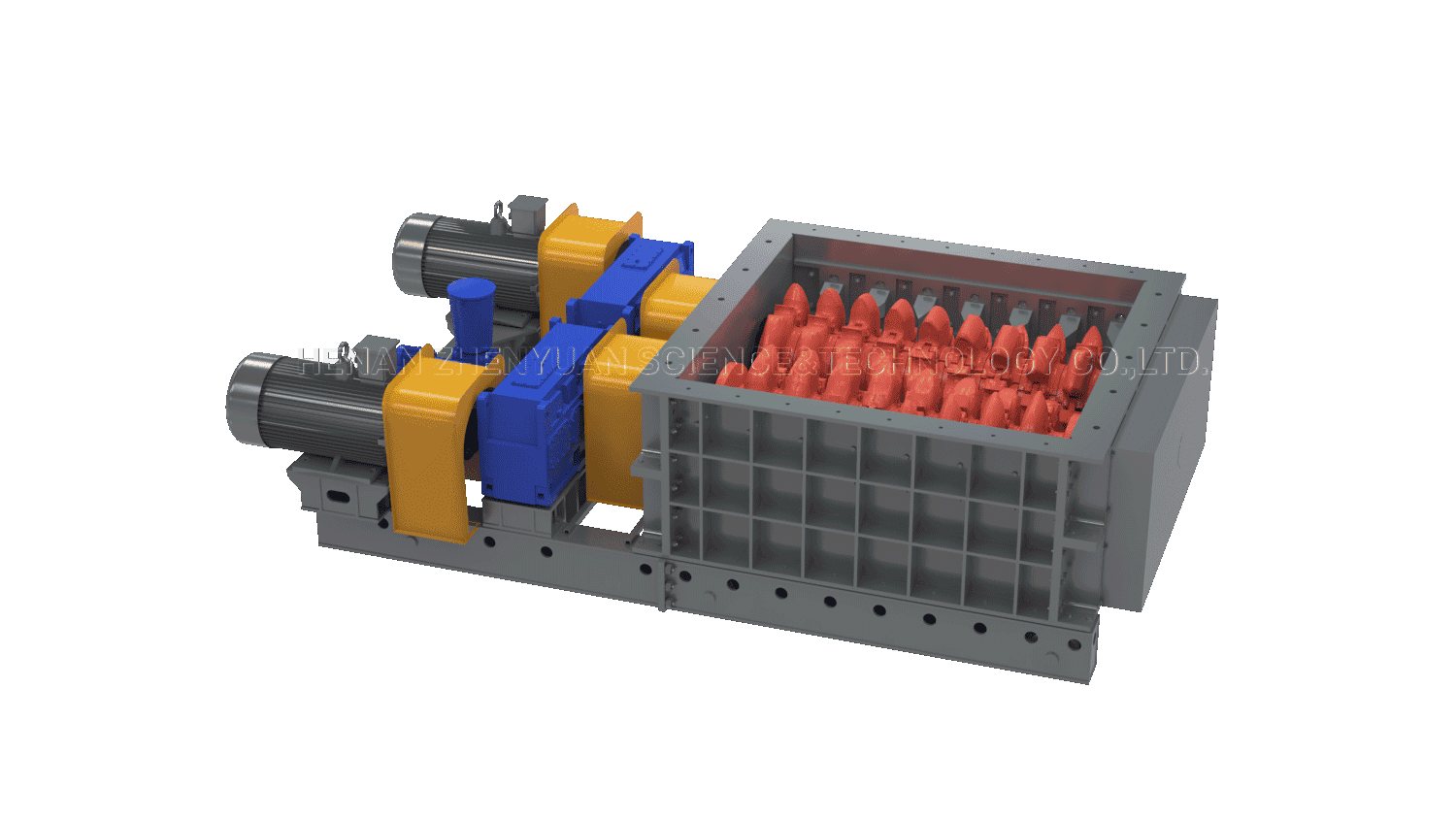

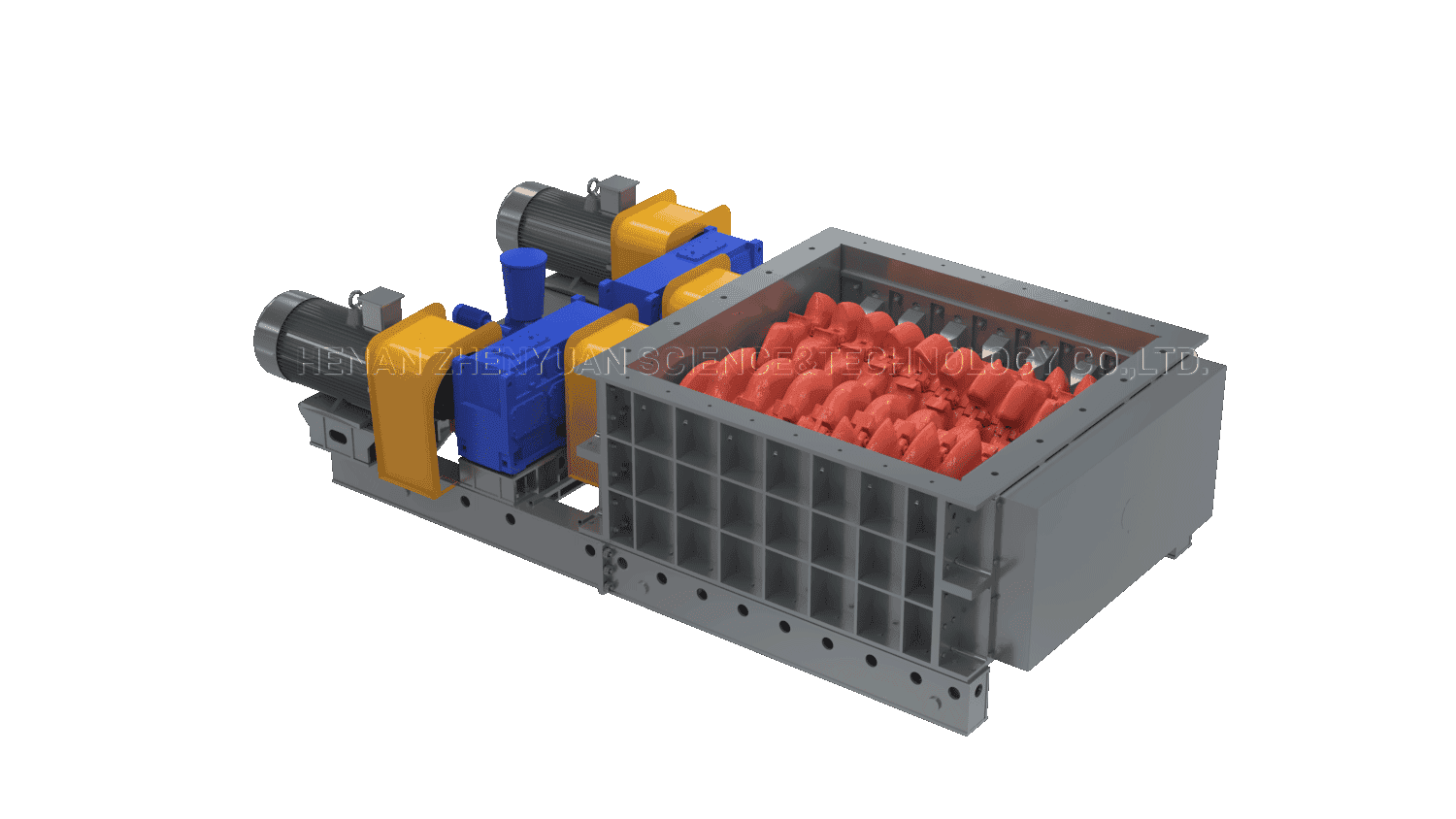

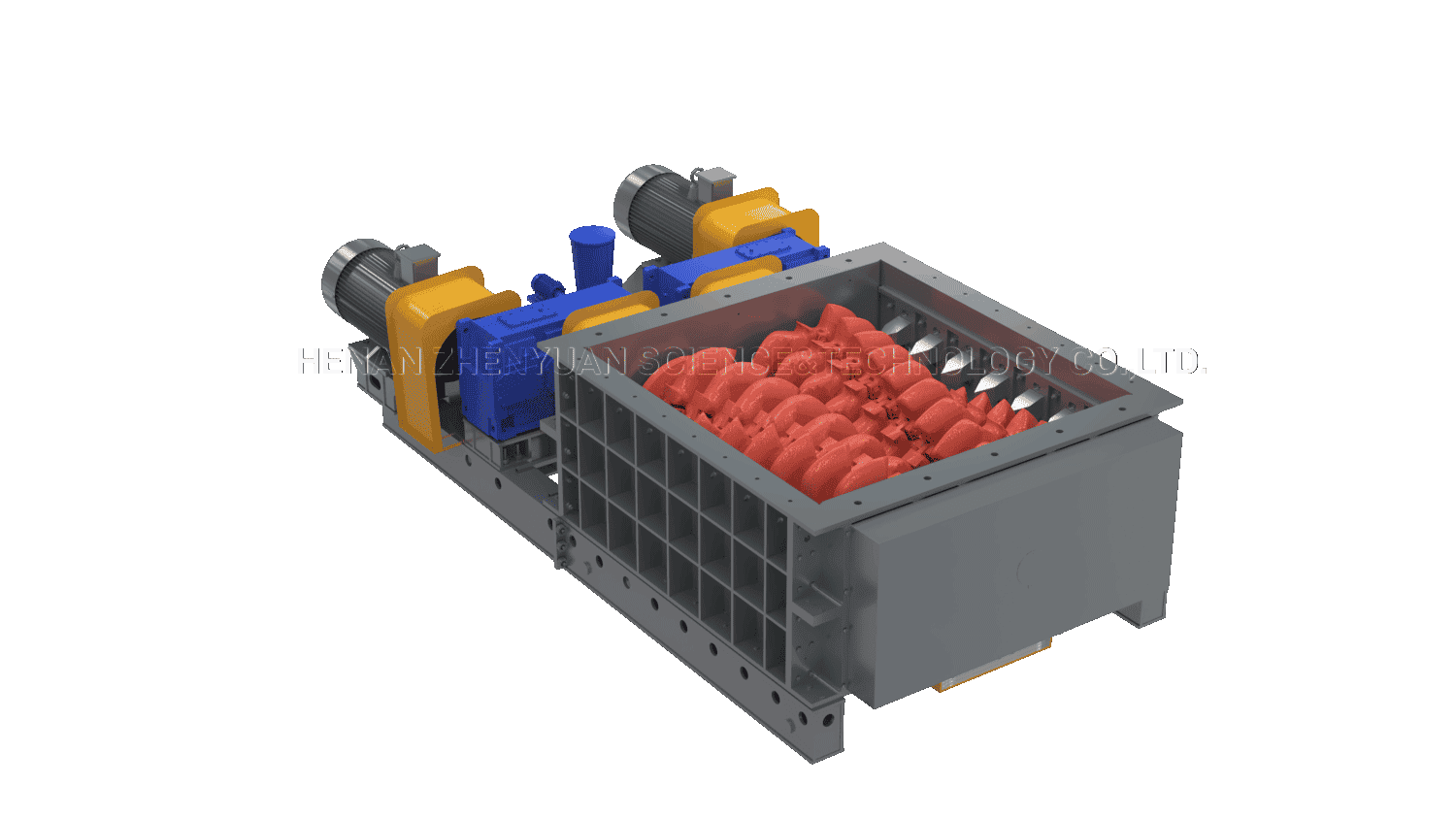

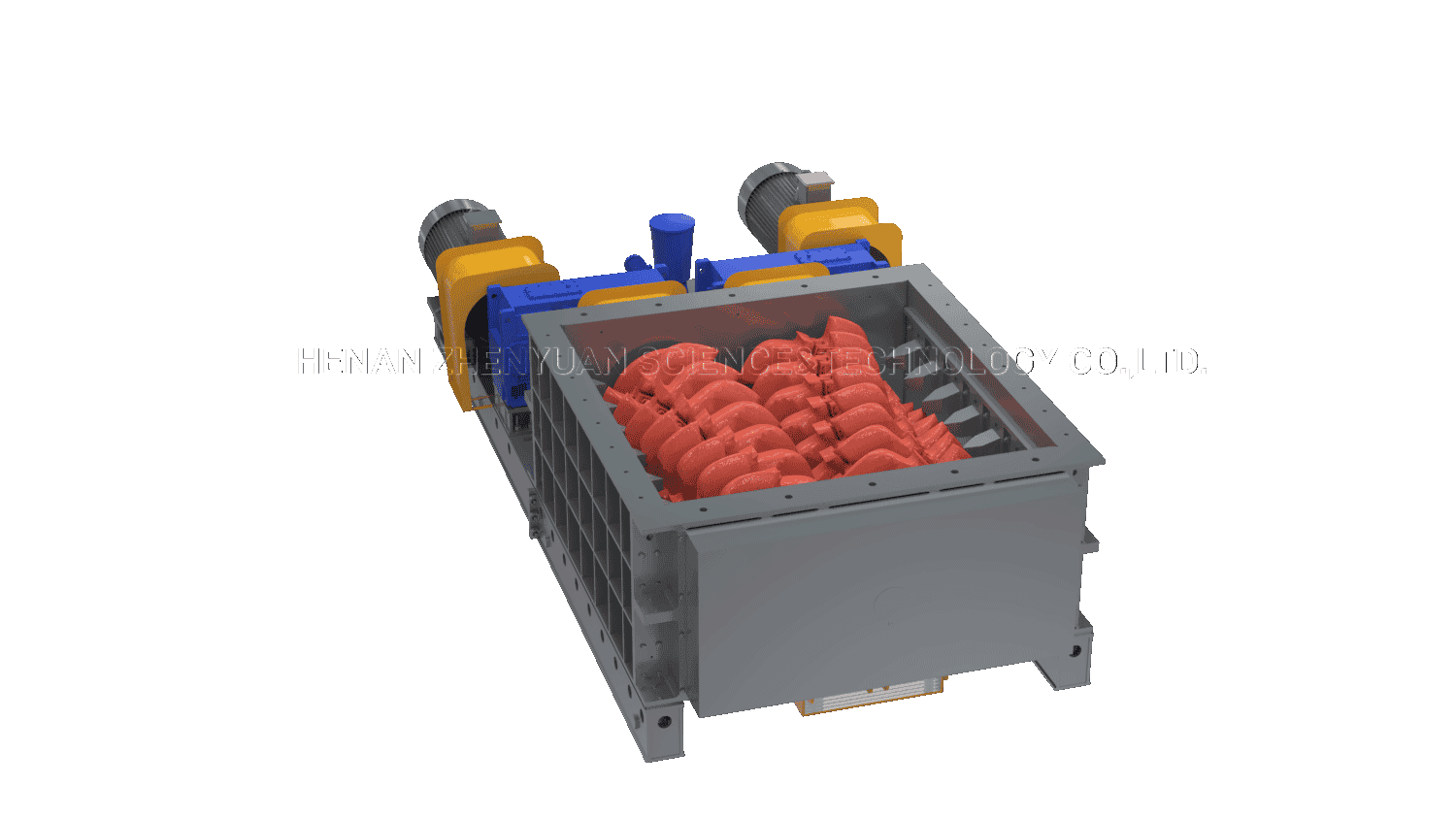

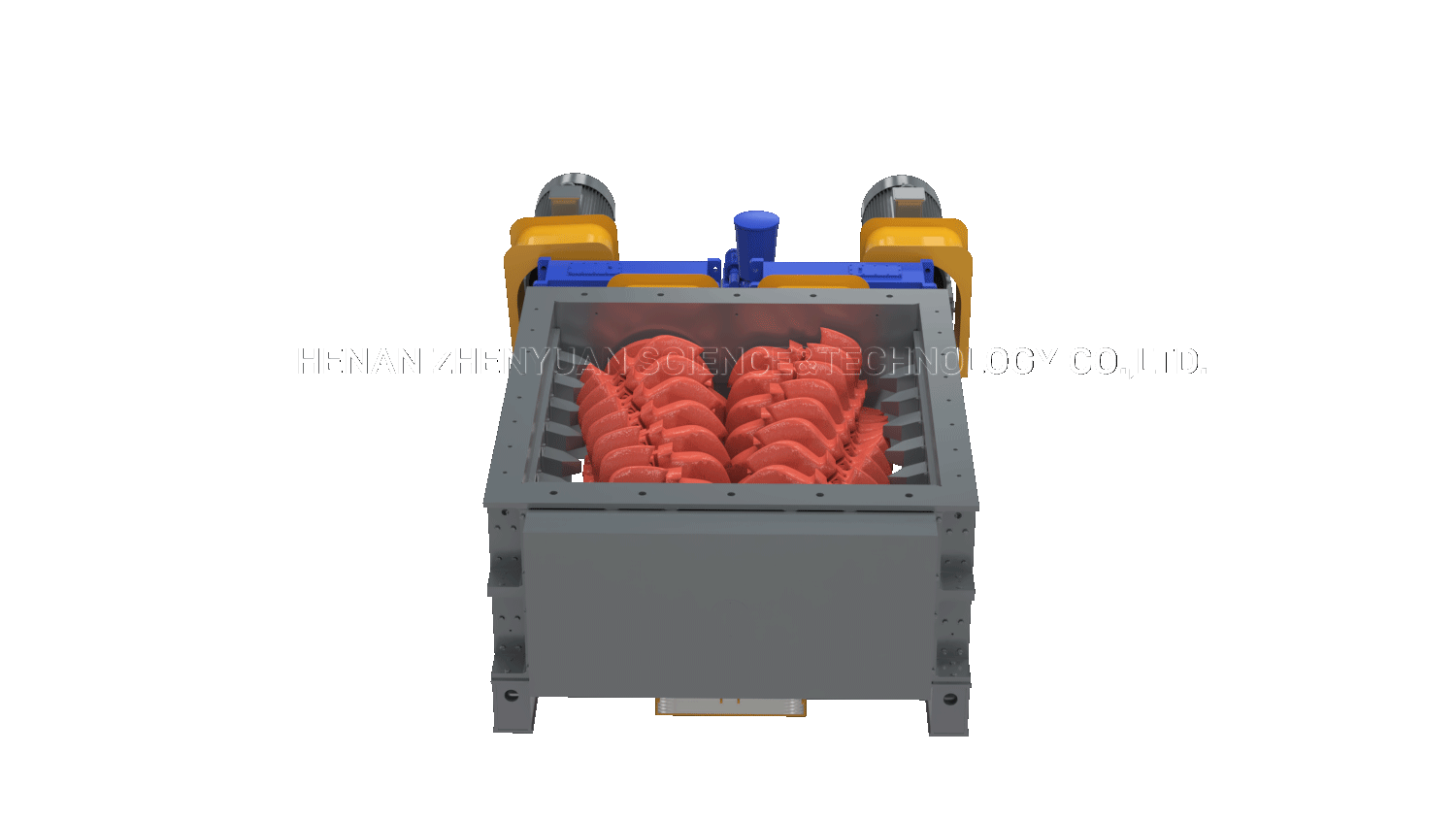

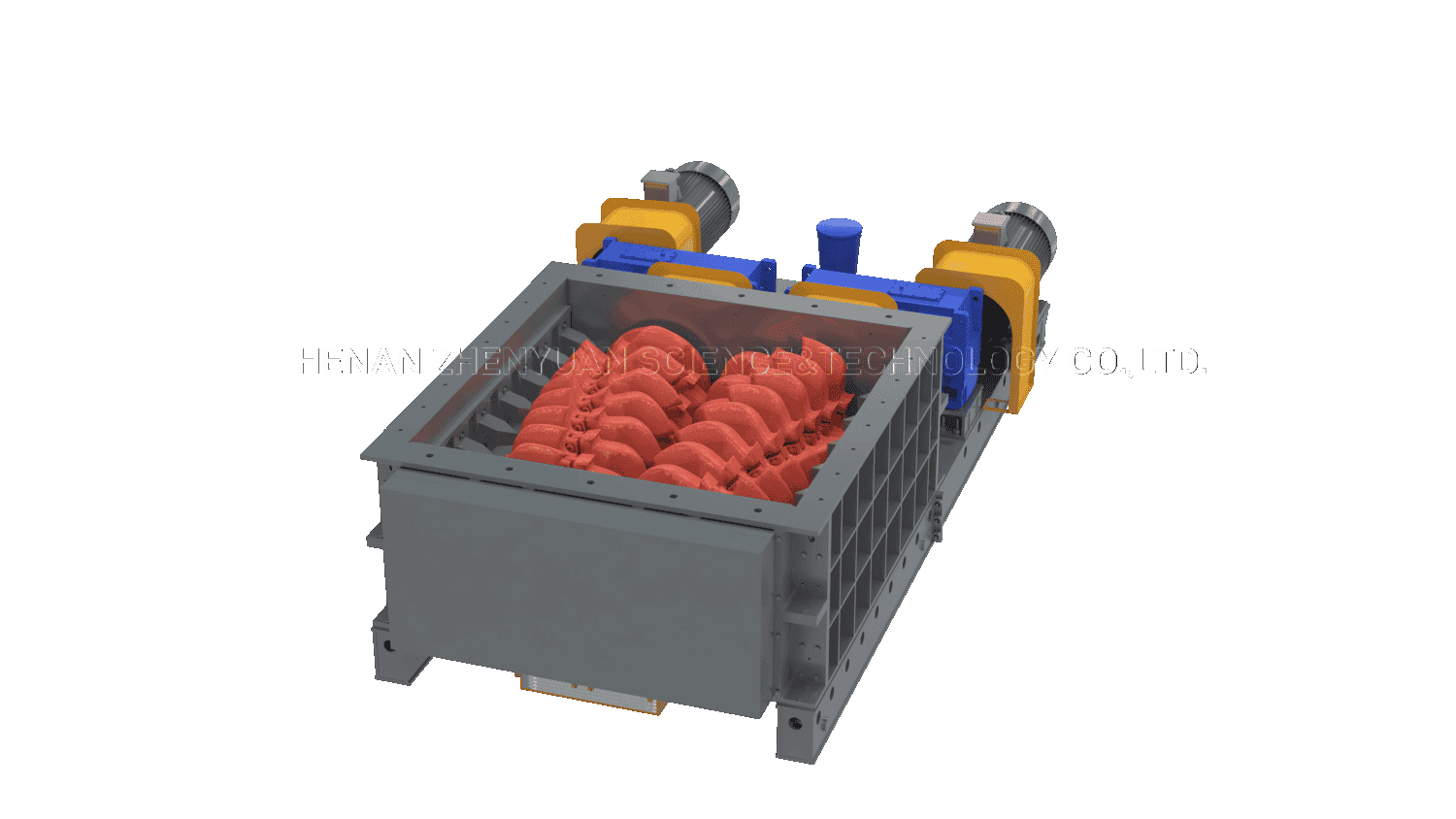

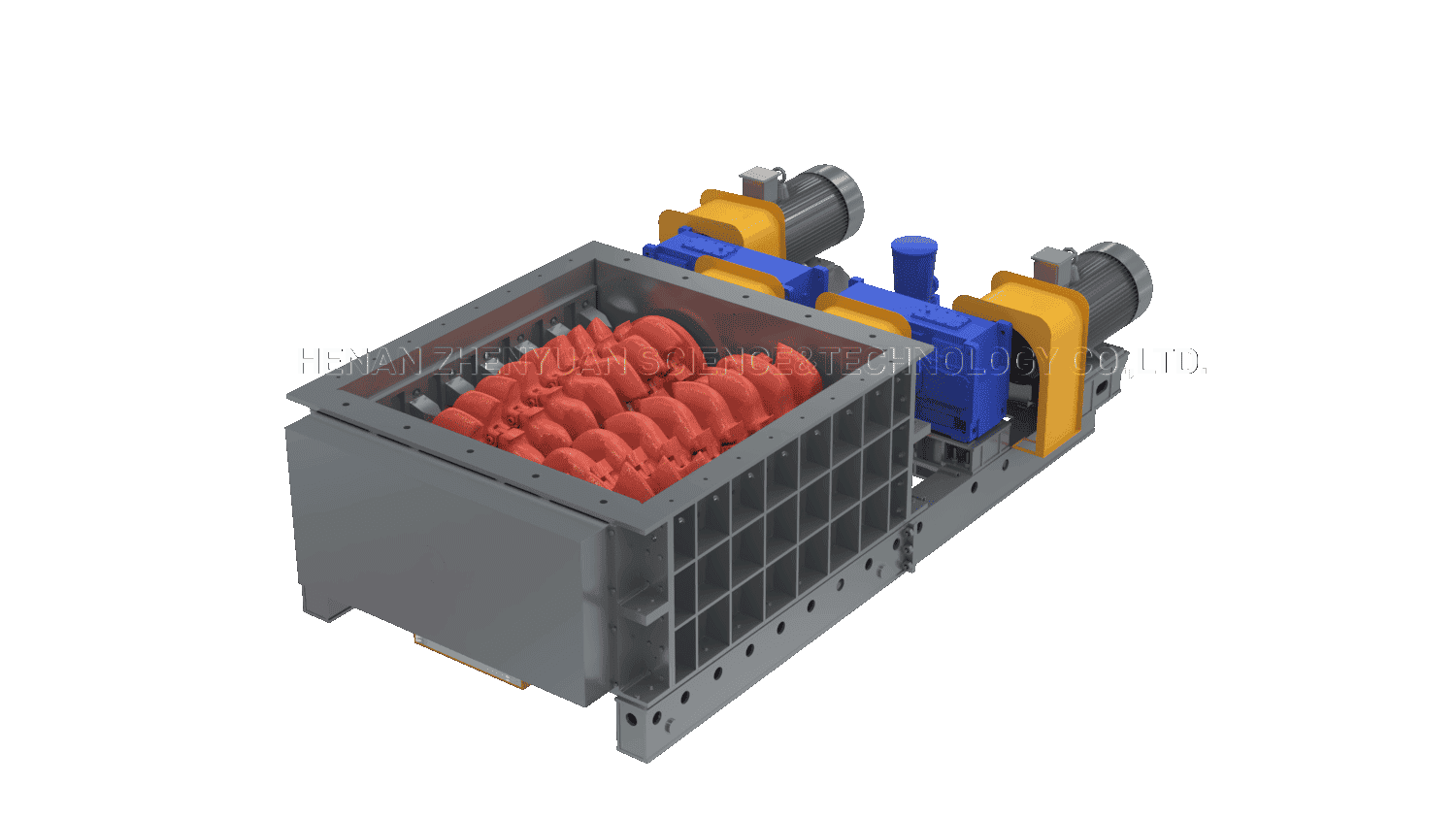

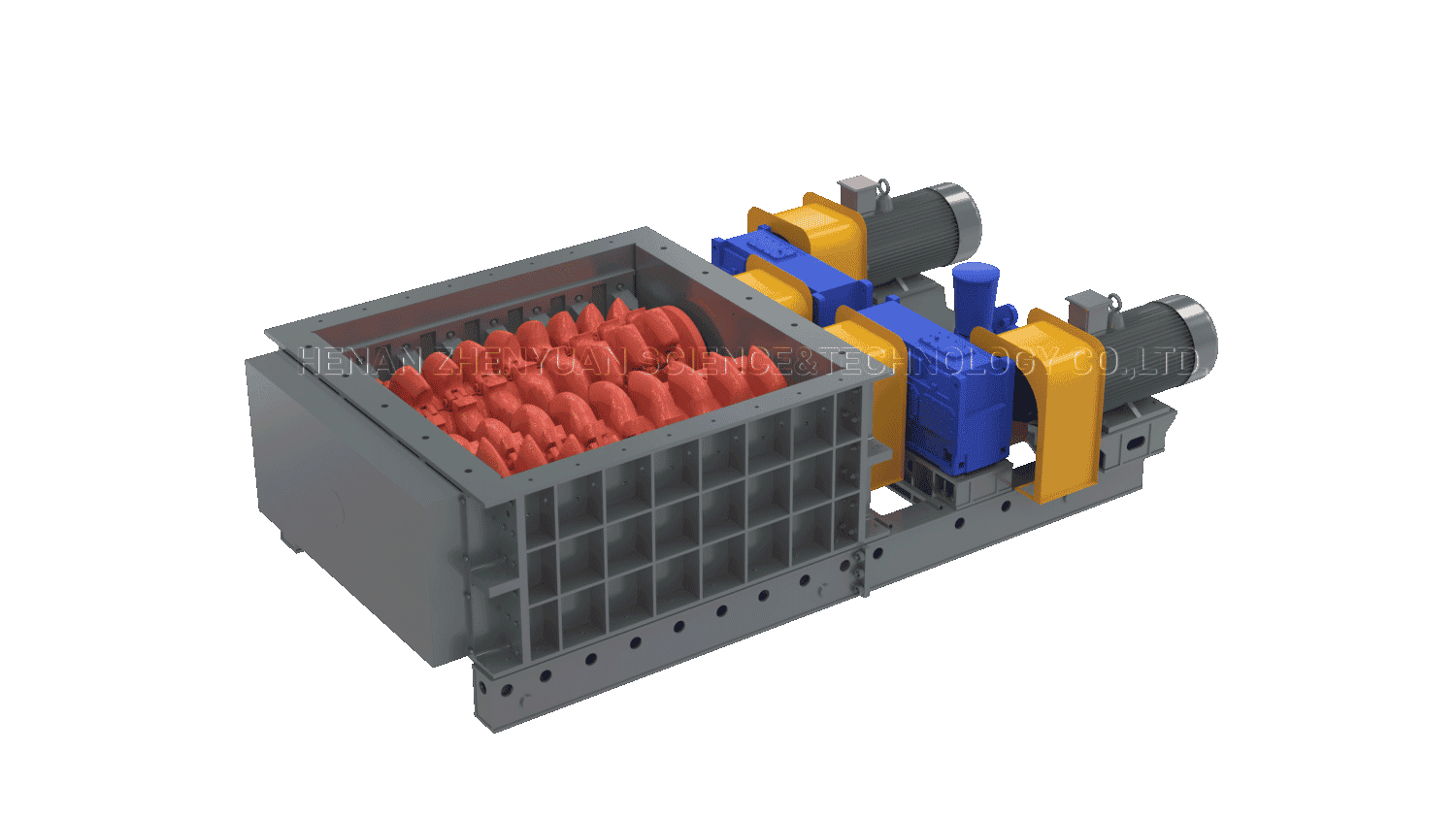

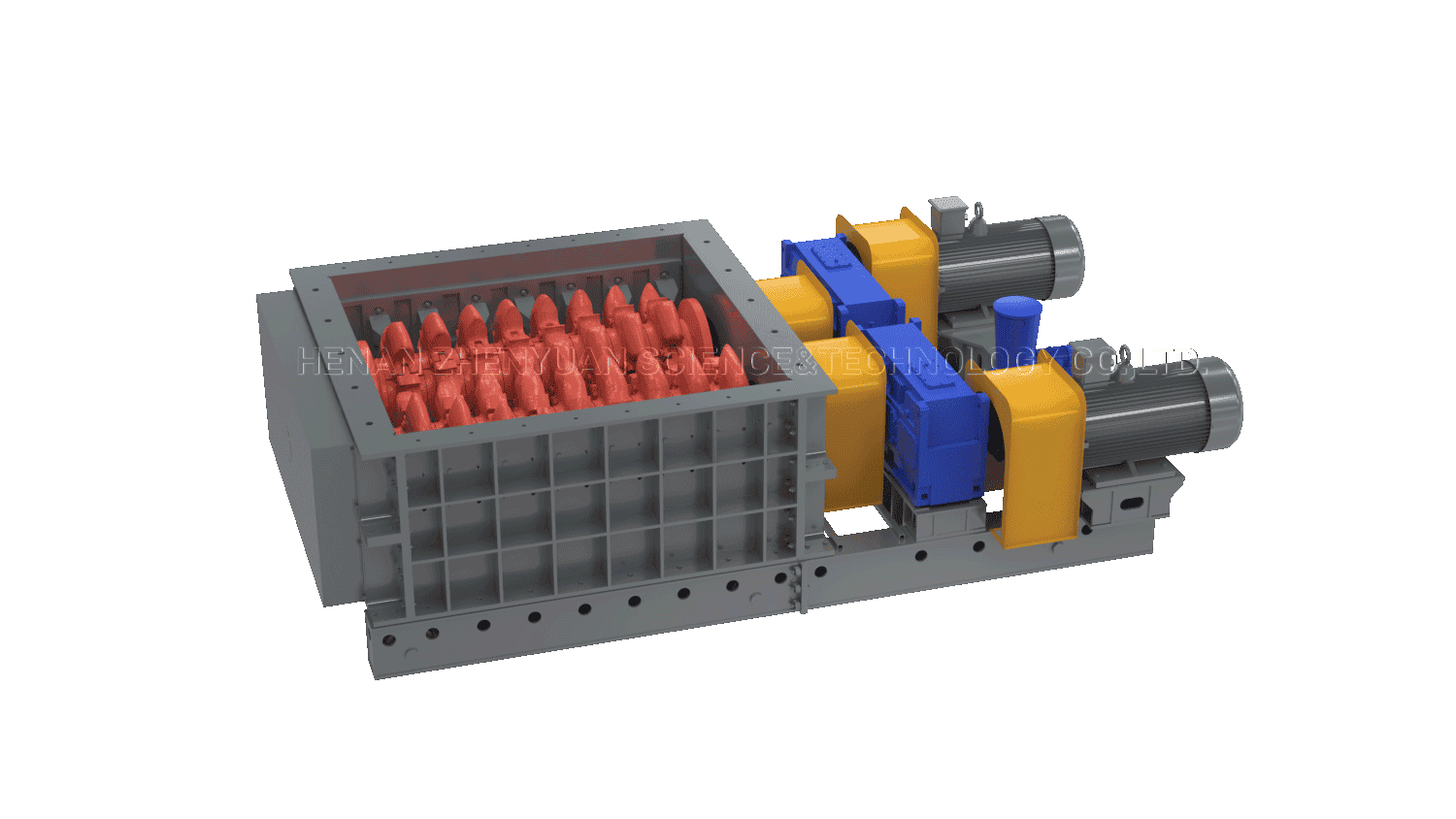

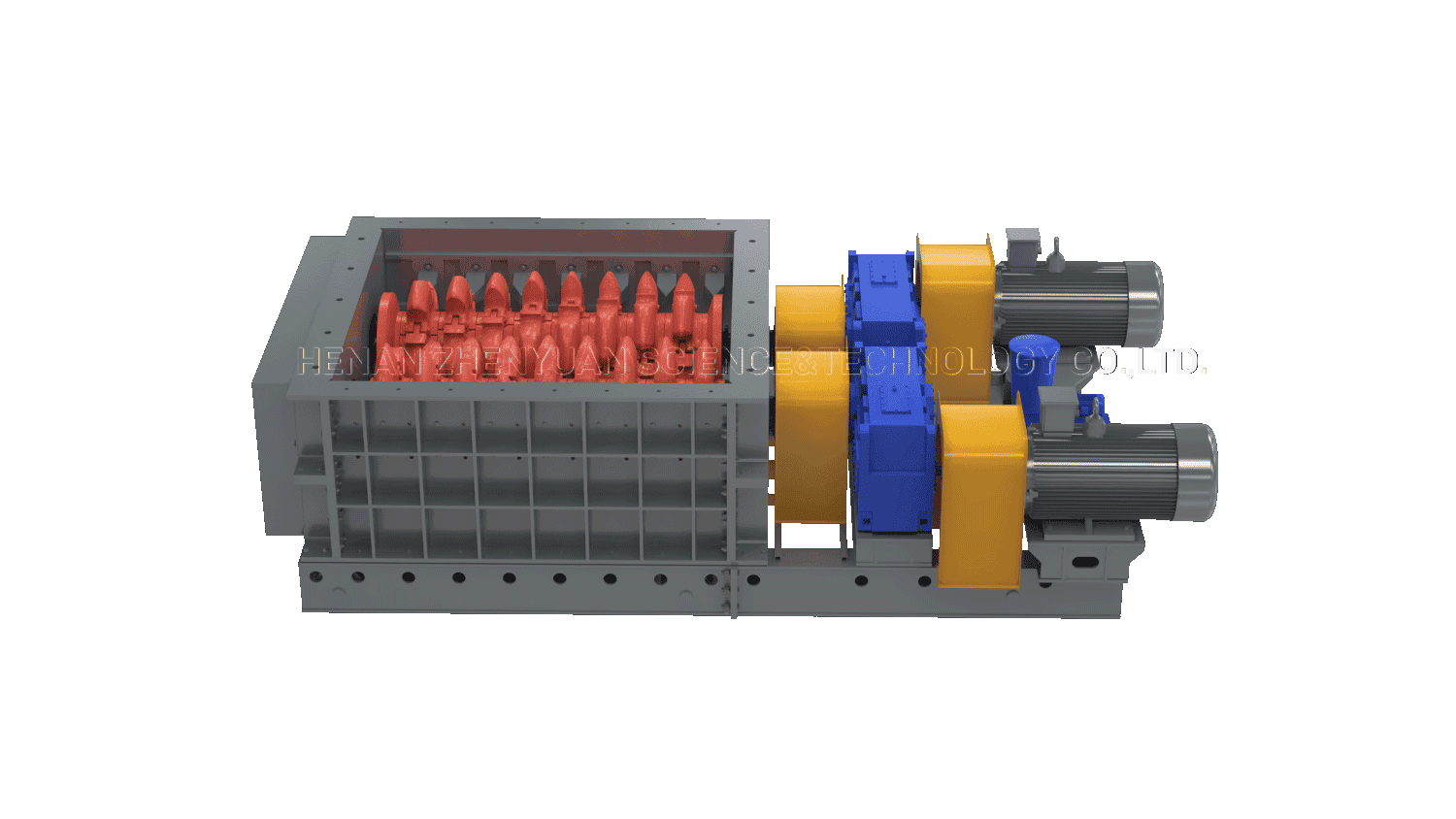

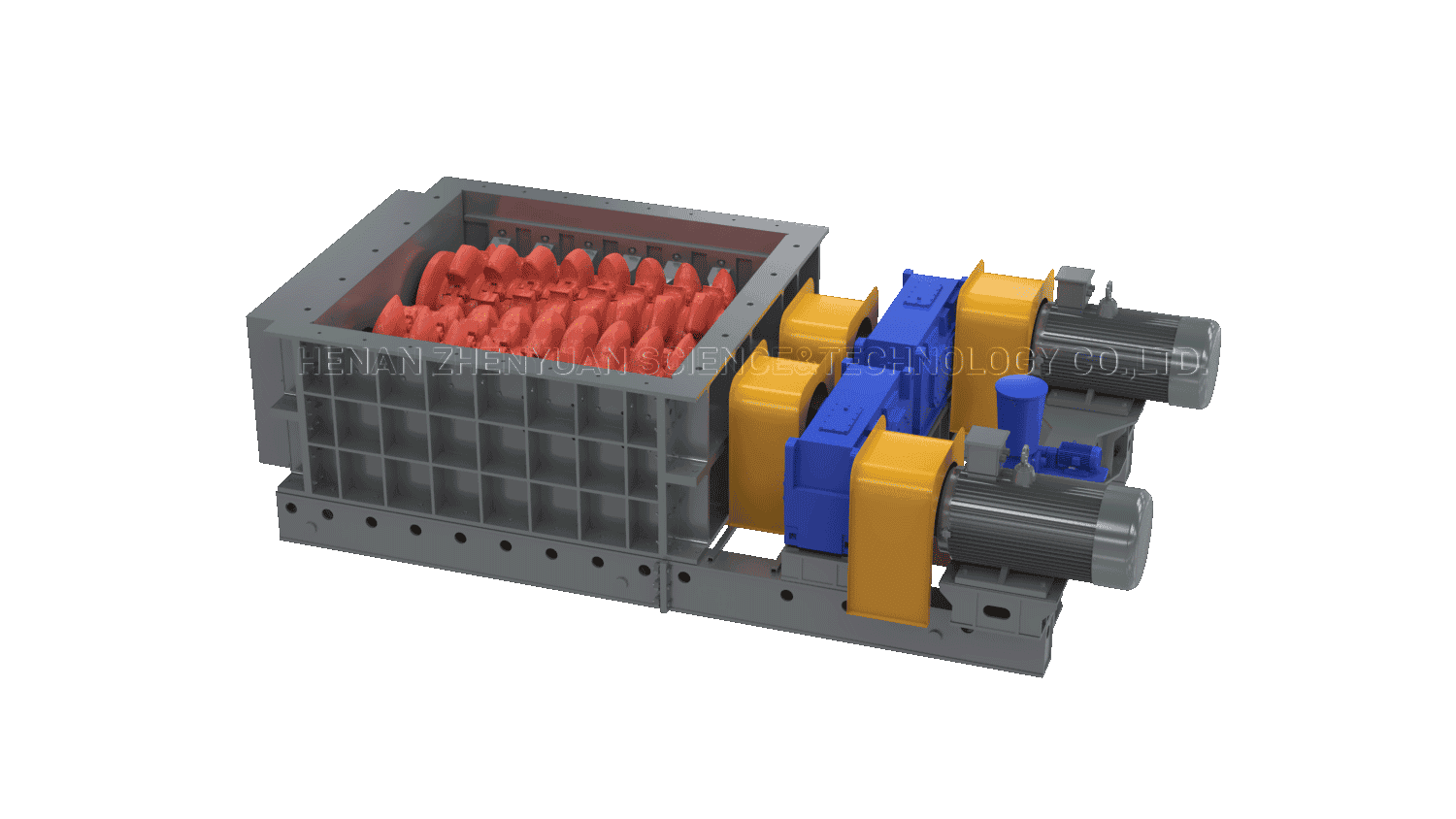

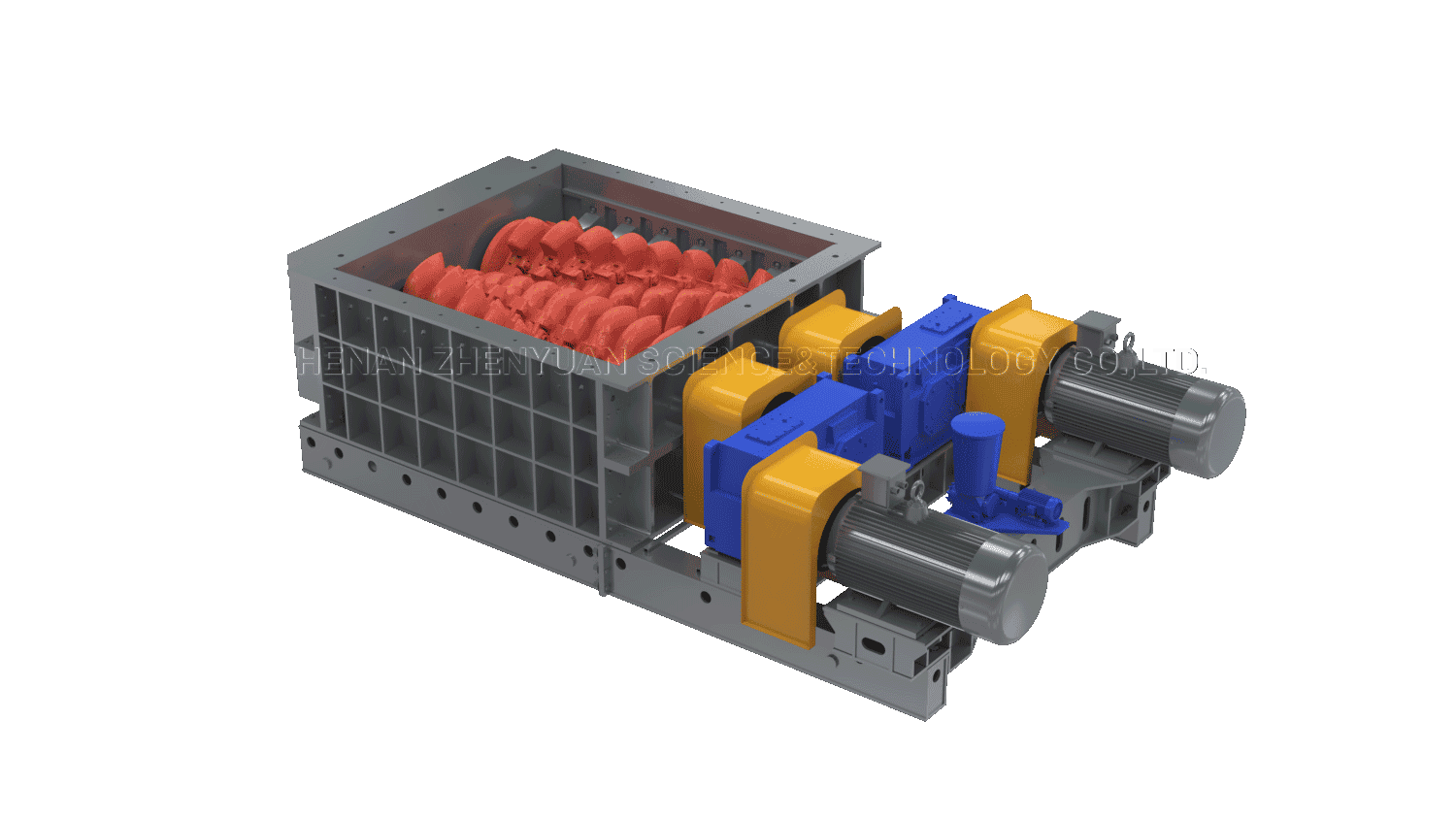

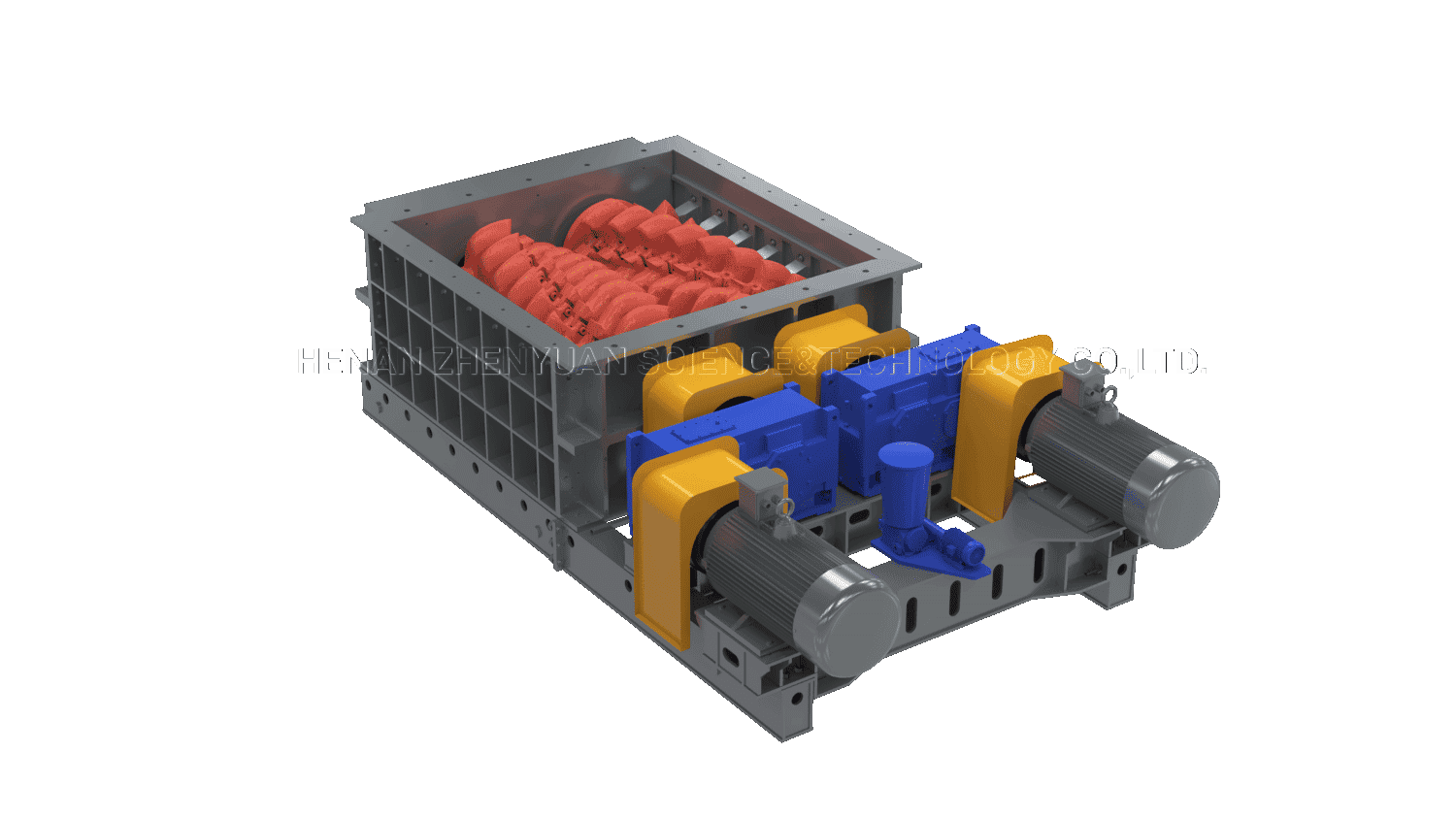

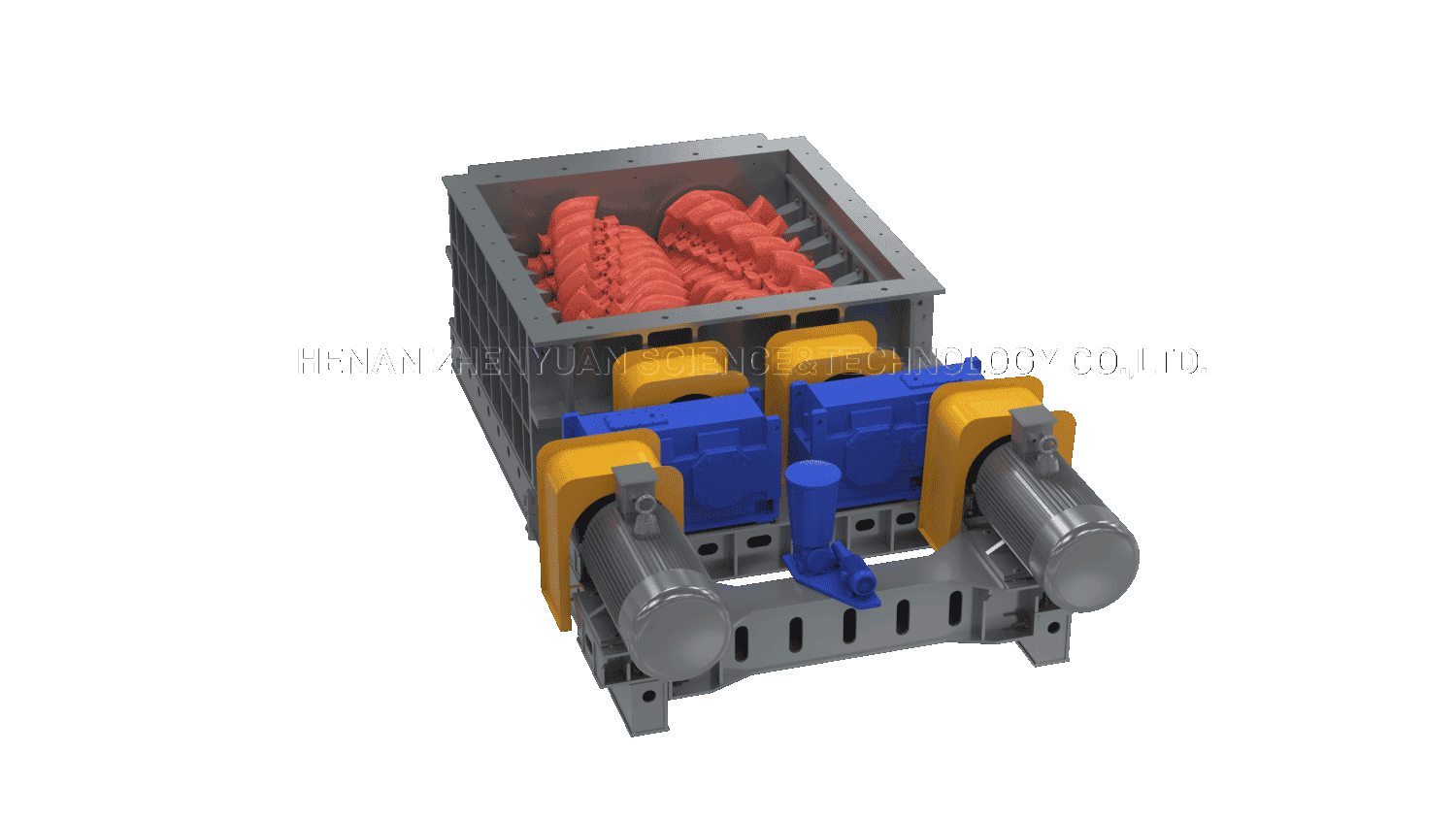

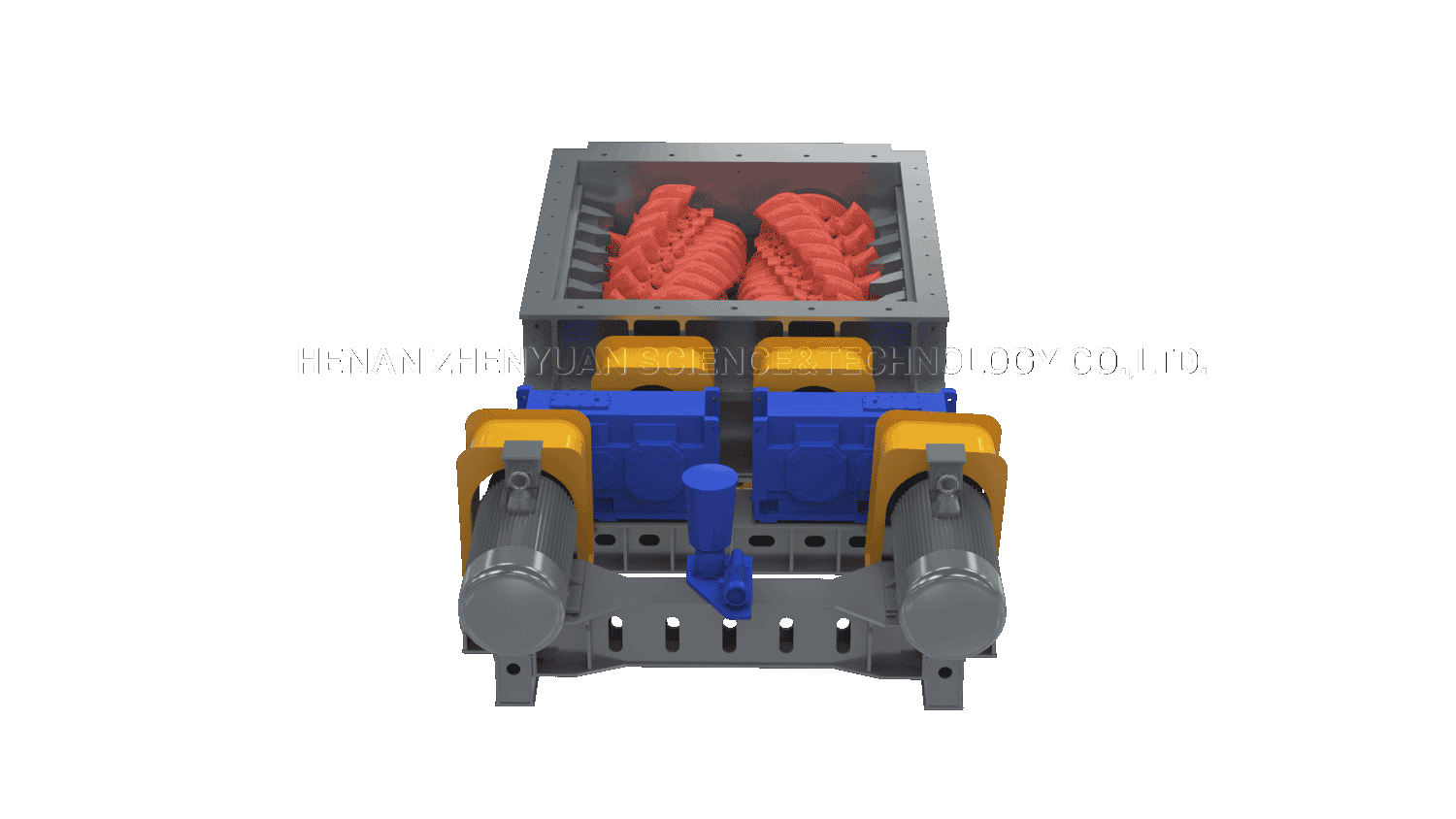

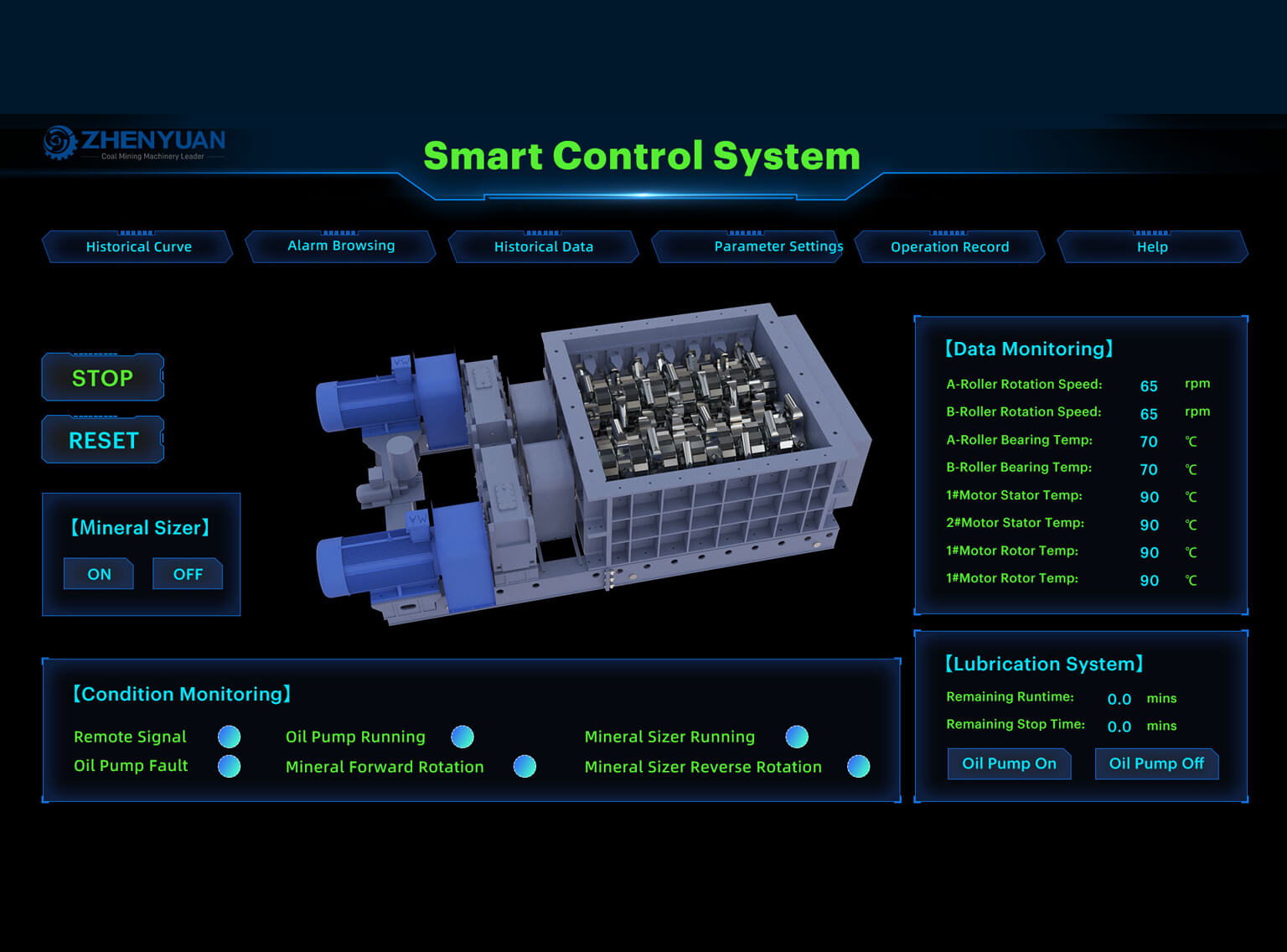

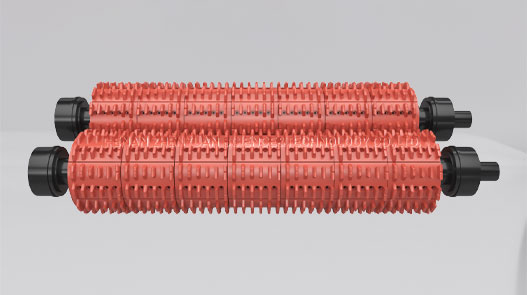

Mineral Sizer is an innovative device integrating high-efficiency crushing and screening functions. Featuring modular design, mineral sizer primarily consists of an electric motor, torque-limiting fluid coupling, connection housing, gearbox, coupling, teeth rollers, and main frame. It incorporates both primary mineral sizer and secondary mineral sizer.

The motors drive the two teeth rollers to rotate in forward or reverse directions, synchronously completing material crushing and screening. Qualified materials pass through inter-teeth spaces into discharge chutes, while oversized particles undergo comprehensive fragmentation, shearing, and tensile forces exerted by roller teeth, finally discharged from the outlet.

Innovative shear crushing technology effectively reduces the fines generation,ensuring high yield and a cleaner working environment.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Primary Mineral Sizer |

||||

|

150 Series Primary Mineral Sizer |

||||

|

Model&Specification |

2PLF-150/250 |

2PLF-150/300 |

2PLF-150/350 |

2PLF-150/400 |

|

Roller Diameter(mm) |

1500 |

1500 |

1500 |

1500 |

|

Roller Length(mm) |

2500 |

3000 |

3500 |

4000 |

|

Input Size(mm) |

≤1500 |

≤1500 |

≤1500 |

≤1500 |

|

Output Size(mm) |

≤300 |

≤300 |

≤300 |

≤300 |

|

Capacity(t/h) |

≤4500 |

≤5500 |

≤6500 |

≤7500 |

|

140 Series Primary Mineral Sizer |

||||

|

Model&Specification |

2PLF-140/200 |

2PLF-140/250 |

2PLF-140/300 |

2PLF-140/350 |

|

Roller Diameter(mm) |

1400 |

1400 |

1400 |

1400 |

|

Roller Length(mm) |

2000 |

2500 |

3000 |

3500 |

|

Input Size(mm) |

≤1400 |

≤1400 |

≤1400 |

≤1400 |

|

Output Size(mm) |

≤300 |

≤300 |

≤300 |

≤300 |

|

Capacity(t/h) |

≤3000 |

≤4000 |

≤5000 |

≤6000 |

|

120 Series Primary Mineral Sizer |

||||

|

Model&Specification |

2PLF-120/150 |

2PLF-120/200 |

2PLF-120/250 |

2PLF-120/300 |

|

Roller Diameter(mm) |

1200 |

1200 |

1200 |

1200 |

|

Roller Length(mm) |

1500 |

2000 |

2500 |

3000 |

|

Input Size(mm) |

≤1200 |

≤1200 |

≤1200 |

≤1200 |

|

Output Size(mm) |

≤300 |

≤300 |

≤300 |

≤300 |

|

Capacity(t/h) |

≤1500 |

≤2000 |

≤2500 |

≤3000 |

|

100 Series Primary Mineral Sizer |

||||

|

Model&Specification |

2PLF-100/120 |

2PLF-100/150 |

2PLF-100/200 |

2PLF-100/250 |

|

Roller Diameter(mm) |

1000 |

1000 |

1000 |

1000 |

|

Roller Length(mm) |

1200 |

1500 |

2000 |

2500 |

|

Input Size(mm) |

≤1000 |

≤1000 |

≤1000 |

≤1000 |

|

Output Size(mm) |

≤300 |

≤300 |

≤300 |

≤300 |

|

Capacity(t/h) |

≤800 |

≤1200 |

≤1500 |

≤2000 |

|

Secondary Mineral Sizer |

||||||||||

|

100 Series Secondary Mineral Sizer |

||||||||||

|

Model&Specification |

2PLF-100/150 |

2PLF-100/200 |

2PLF-100/250 |

2PLF-100/300 |

2PLF100/350 |

|||||

|

Roller Diameter(mm) |

1000 |

1000 |

1000 |

1000 |

1000 |

|||||

|

Roller Length(mm) |

1500 |

2000 |

2500 |

3000 |

3500 |

|||||

|

Input Size(mm) |

≤400 |

≤400 |

≤400 |

≤400 |

≤400 |

|||||

|

Output Size(mm) |

50-150 |

50-150 |

50-150 |

50-150 |

50-150 |

|||||

|

Capacity(t/h) |

400-800 |

500-1000 |

650-1200 |

800-1500 |

1000-1800 |

|||||

|

80 Series Secondary Mineral Sizer |

||||||||||

|

Model&Specification |

2PLF-80/150 |

2PLF-80/200 |

2PLF-80/250 |

2PLF-80/300 |

||||||

|

Roller Diameter(mm) |

800 |

800 |

800 |

800 |

||||||

|

Roller Length(mm) |

1500 |

2000 |

2500 |

3000 |

||||||

|

Input Size(mm) |

≤300 |

≤300 |

≤300 |

≤300 |

||||||

|

Output Size(mm) |

50-150 |

50-150 |

50-150 |

50-150 |

||||||

|

Capacity(t/h) |

300-500 |

400-800 |

500-1200 |

600-1500 |

||||||

|

60 Series Secondary Mineral Sizer |

||||||||||

|

Model&Specification |

2PLF-60/120 |

2PLF-60/160 |

2PLF-60/200 |

|||||||

|

Roller Diameter(mm) |

600 |

600 |

600 |

|||||||

|

Roller Length(mm) |

1200 |

1600 |

2000 |

|||||||

|

Input Size(mm) |

≤300 |

≤300 |

≤300 |

|||||||

|

Output Size(mm) |

50-150 |

50-150 |

50-150 |

|||||||

|

Capacity(t/h) |

200-400 |

250-600 |

300-800 |

|||||||

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

Processing Materials: Lignite Coal/Long Flame Coal

Input Size: 0-1200mm

Output Size: 0-120mm

Capacity: 1000-1200TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-30mm, 30-80mm

Capacity: 2500-3000TPH

Processing Materials: Raw Coal

Input Size: 0-1200mm

Output Size: 0-80mm

Capacity:2000-2500TPH

Processing Materials: Raw Coal

Input Size: 0-1000mm

Output Size: 0-80mm

Capacity:2000-2500TPH

Processing Materials: Raw Coal

Input Size: 0-1500mm

Output Size: 0-300mm

Capacity: 3500-4000TPH

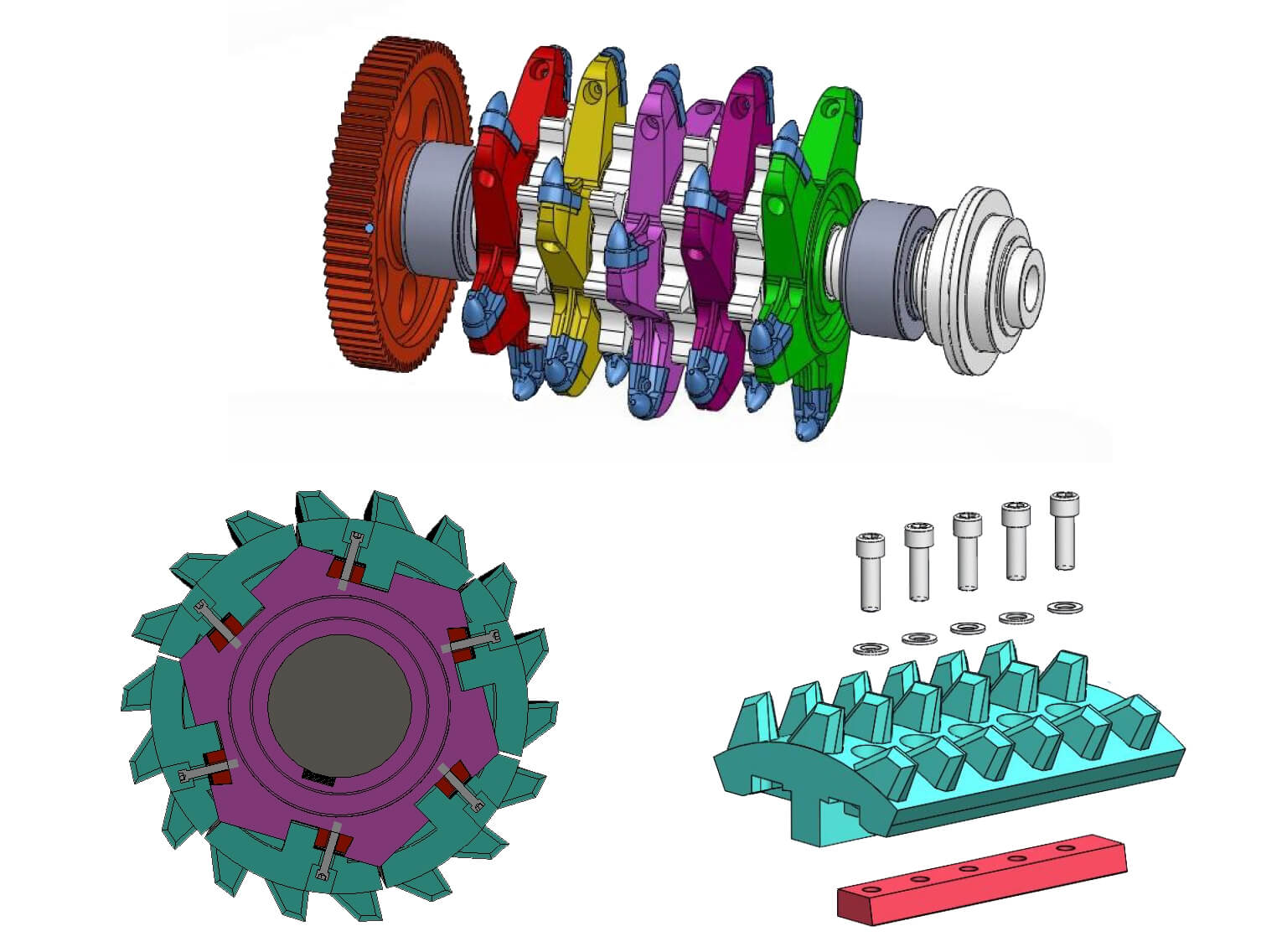

Synchronous Gear

Fluid Coupling

Oil Pump

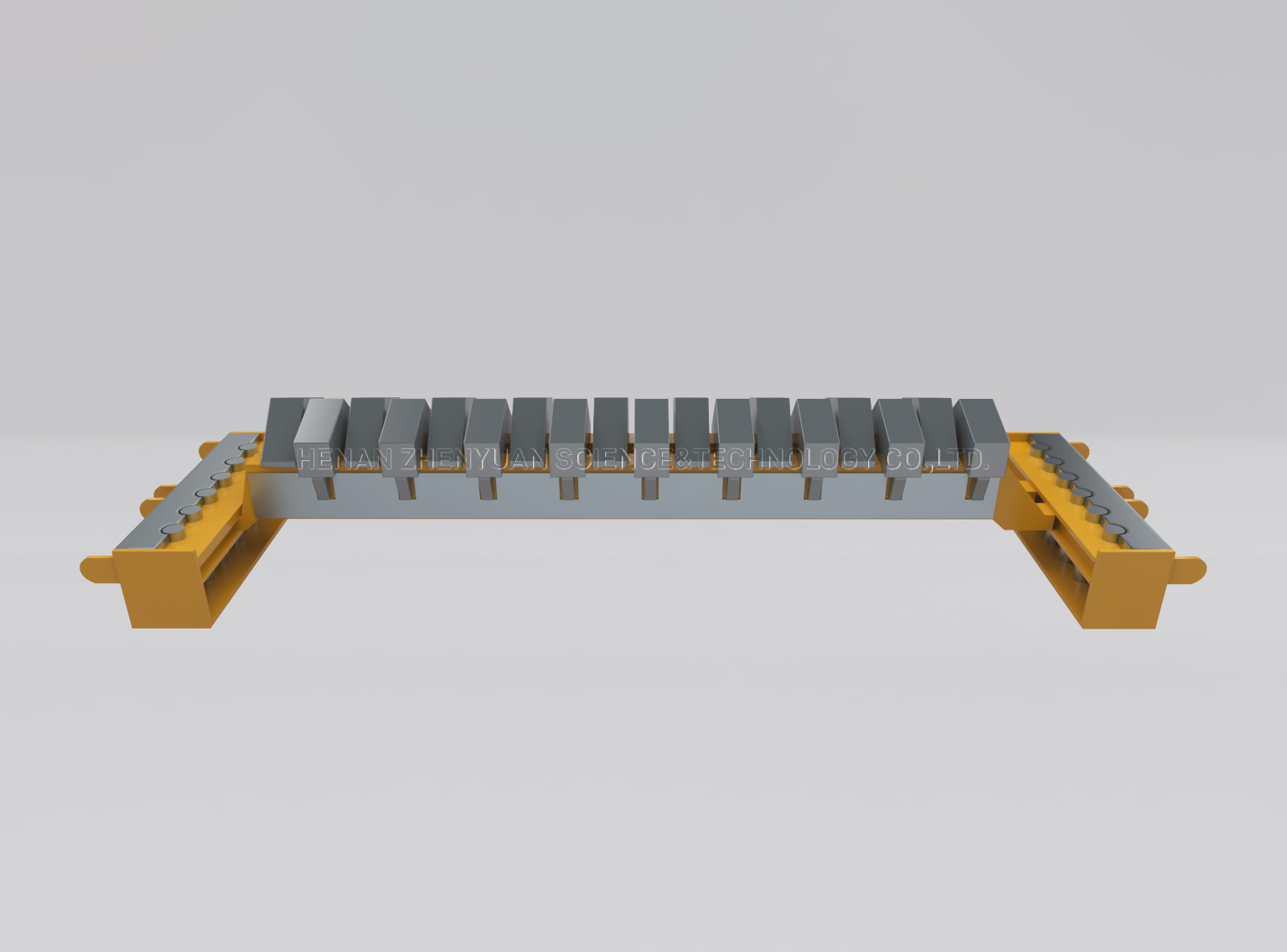

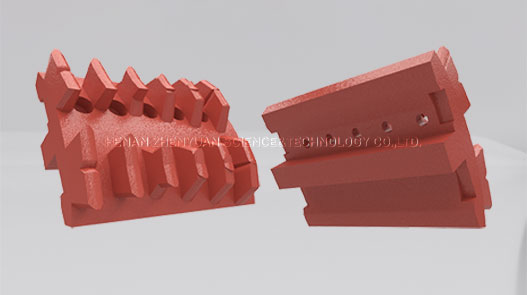

Secondary Teeth Plate

Secondary Teeth Roller Assembly

Primary Teeth Roller Assembly