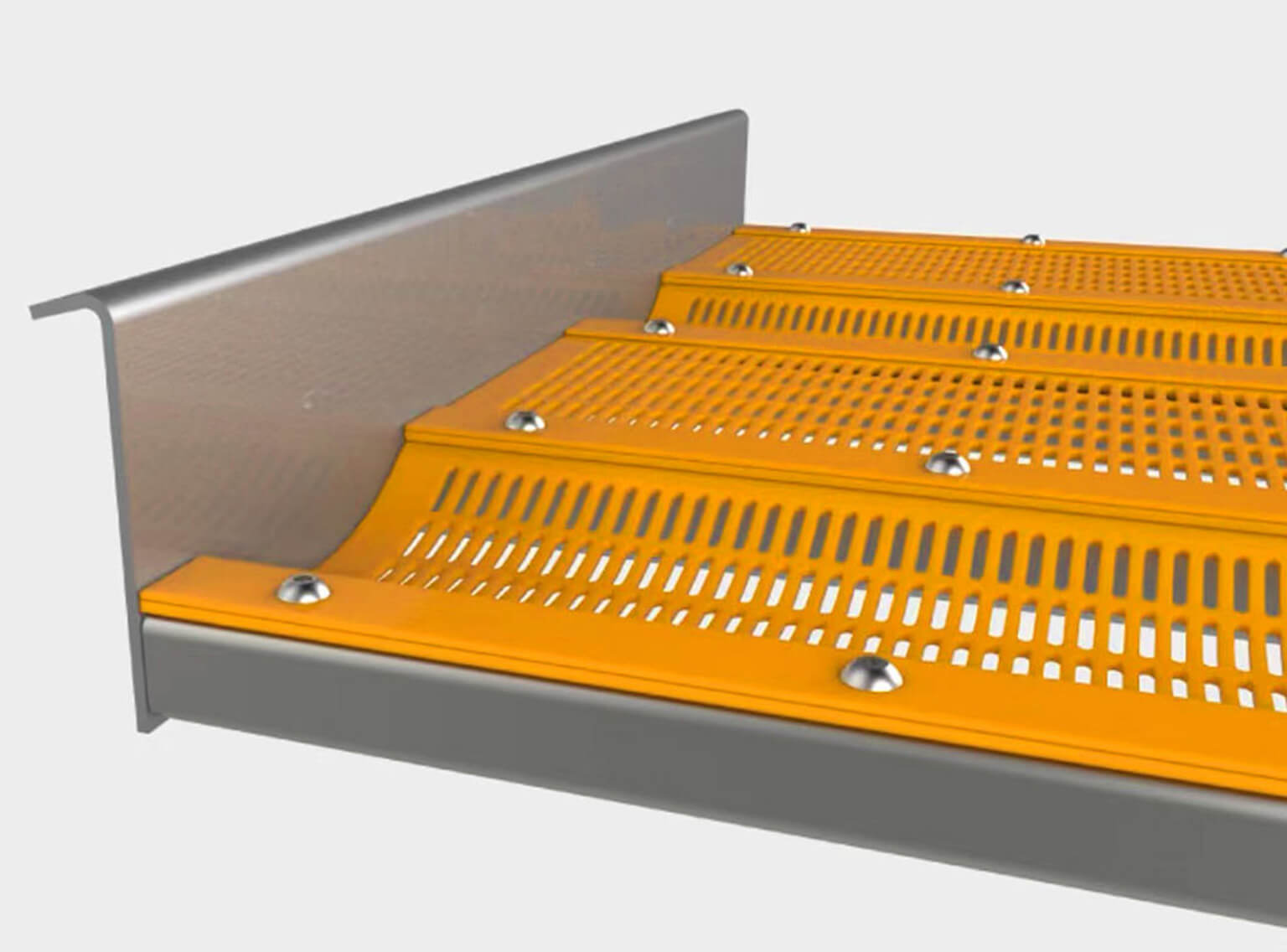

The screen plate does not require any bolts for fixation, making it easy to install, disassemble, and replace quickly.

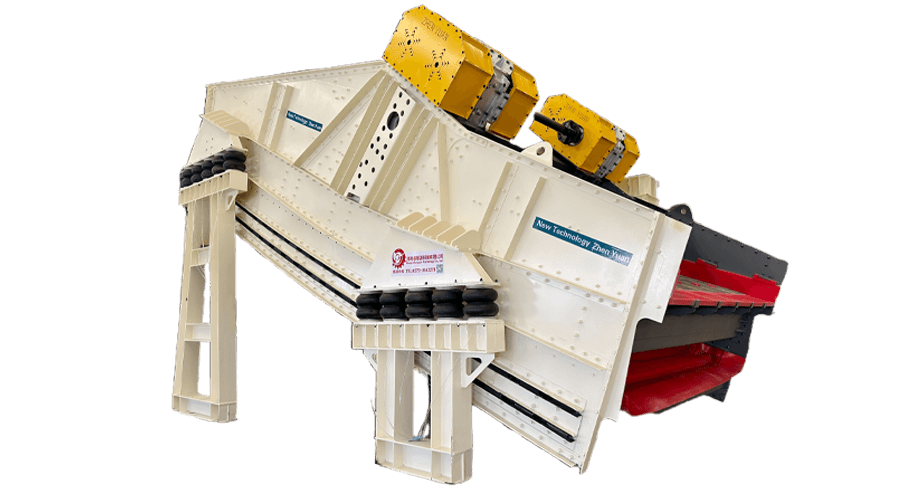

The screen is mounted on hollow rubber springs, providing excellent vibration damping and low noise generation.

The vibration amplitude of the floating screen frame is adjustable, with a vibration intensity range of 10-50g.

The grading size can be as small as 3mm (for non-metallic mines) or 0.2mm (for metallic mines).

Compared to other screening equipment with the same screening area, this screen requires the least motor power.

The screening efficiency can exceed 95%.

The screen plate of the Sreader Vibrating Flip-Flow Screen is specially designed to withstand a vibration intensity of 50g and a flexing rate of 800 times per minute, ensuring a long service life.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Screen Plate |

Max. Input Size |

Capacity |

Electrical Motor |

|||

|

Layer(s) |

Area(m2) |

Mesh Size(mm) |

(mm) |

(t/h) |

Power(kw) |

Qty(pcs) |

|

|

VFDB(SF)1861 |

1 |

10.98 |

0.5-8 |

80 |

100-300 |

22 |

1 |

|

2VFDB(SF)1861 |

2 |

10.98×2 |

Upper:8-30 Lower: 0.5-8 |

80 |

200-400 |

30 |

1 |

|

VFDB(SF)2461 |

1 |

14.64 |

0.5-8 |

80 |

150-400 |

37 |

1 |

|

2VFDB(SF)2461 |

2 |

14.64×2 |

Upper:8-30 Lower: 0.5-8 |

80 |

300-500 |

45 |

1 |

|

VFDB(SF)3061 |

1 |

18.3 |

0.5-8 |

100 |

200-600 |

45 |

1 |

|

2VFDB(SF)3061 |

2 |

18.3×2 |

Upper:8-30 Lower: 0.5-8 |

100 |

300-650 |

55 |

1 |

|

VFDB(SF)3685 |

1 |

30.6 |

0.5-8 |

100 |

300-800 |

55 |

1 |

|

2VFDB(SF)3685 |

2 |

30.6×2 |

Upper:8-30 Lower: 0.5-8 |

100 |

500-1050 |

75 |

1 |

|

VFDB(SF)43100 |

1 |

43 |

0.5-8 |

100 |

400-1000 |

75 |

1 |

|

2VFDB(SF)43100 |

2 |

43×2 |

Upper:8-30 Lower: 0.5-8 |

100 |

660-1300 |

90 |

1 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

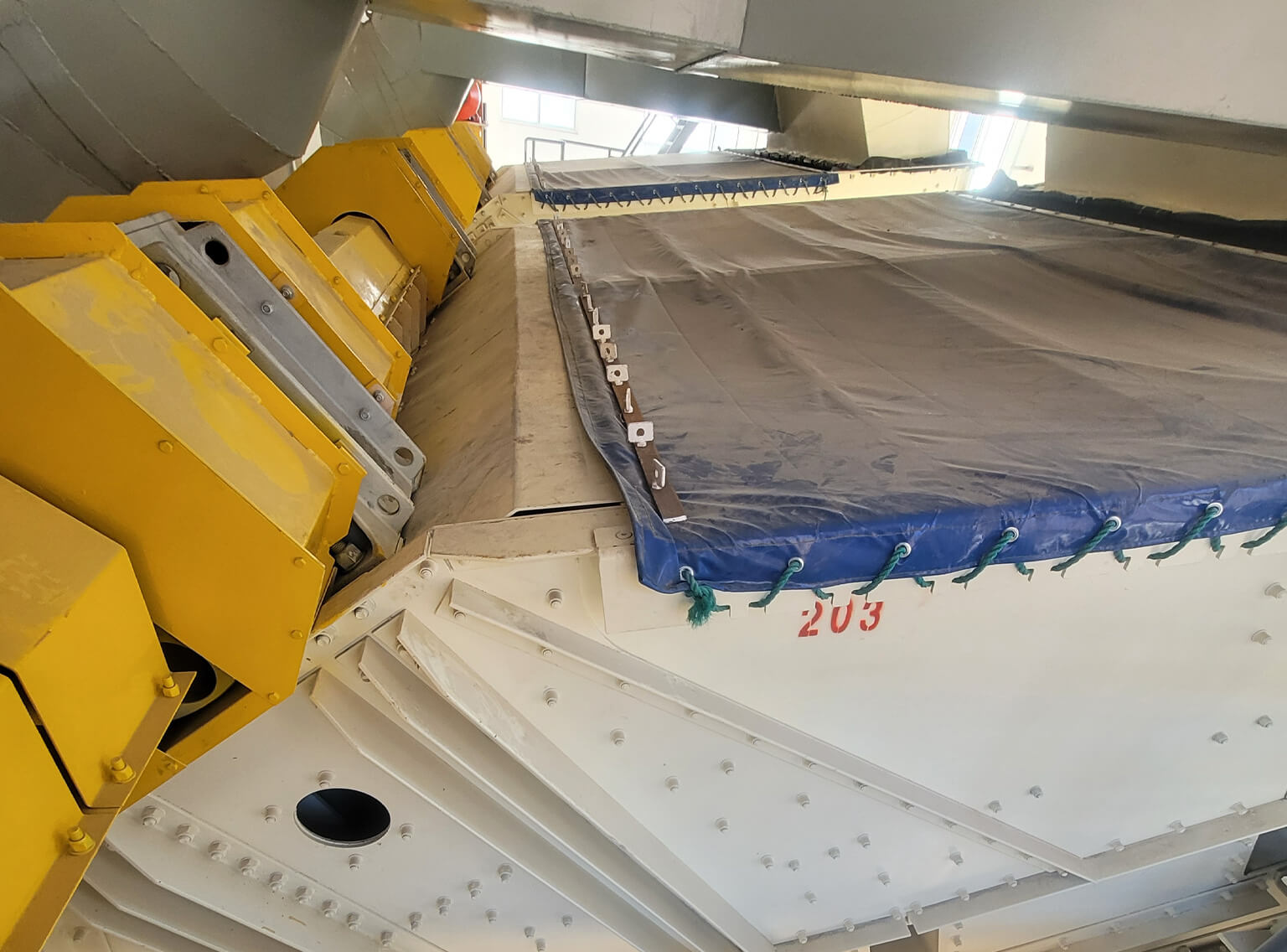

Processing Materials: Coal

Input Size: 0-100mm

Upper Screen Mesh Size: 25mm

Lower Screen Mesh Size: 3mm

Capacity: 300-350TPH

Processing Materials: Raw Coal

Input Size: 0-100mm

Upper Screen Mesh Size: 30mm

Lower Screen Mesh Size: 8mm

Capacity: 800-850TPH